Phosphoric Acid Production Cost Reports

Chemicals

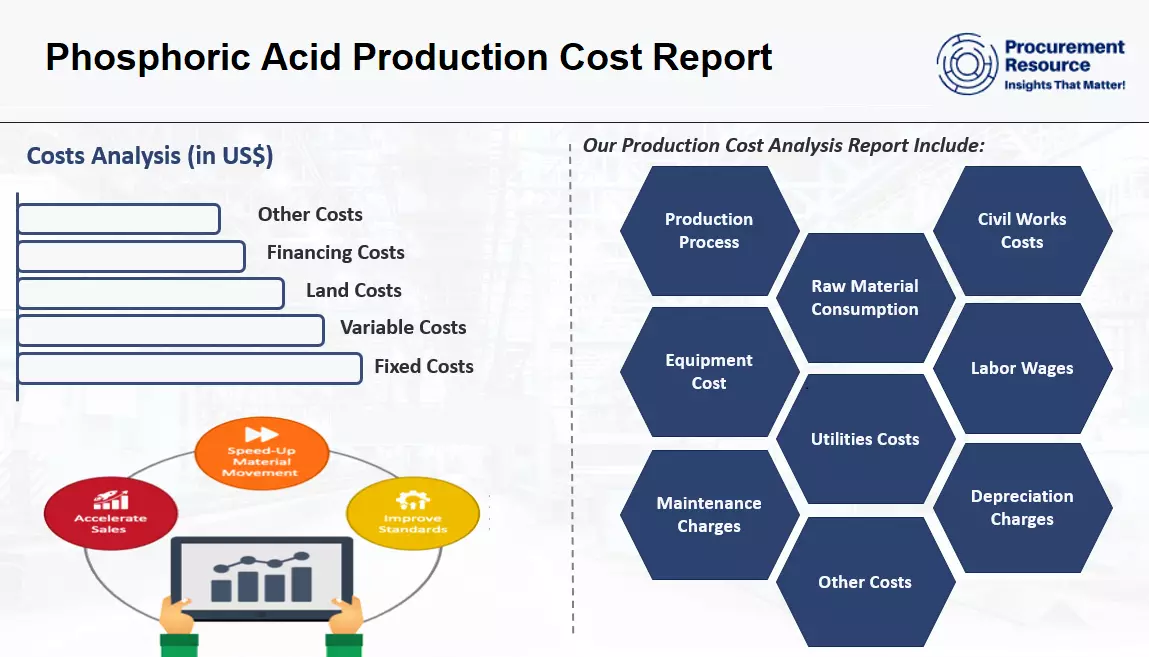

Phosphoric Acid production cost report provides a comprehensive analysis and know-how for setting up a Phosphoric acid production plant. The study covers all the requisite aspects that one needs to know for the production of Phosphoric acid. This includes manufacturing processes, raw material requirements, utility requirements, infrastructure requirements, machinery and technology requirements, manpower requirements, packaging requirements, transportation requirements, etc.

Phosphoric acid or orthophosphoric acid (H3PO4) is the most important oxygen acid of phosphorus. It's a phosphorus oxoacid comprising one oxo and three hydroxy groups covalently linked to a central phosphorus atom. It functions like a solvent, an algal metabolite, a human metabolite, and a fertilizer. It is a conjugate acid of a dihydrogen phosphate and a phosphate ion.

Phosphoric acid, in its pure form, is a crystalline solid that appears like a colourless syrupy liquid in a less concentrated form with no odour. It contains phosphorus and classifies as an inorganic acid. It has a melting point of 42.35 °C and a boiling point of 407 °C, respectively. It has a molar mass of 97.99 g/mol and a density of 1.834 g/cm3. It shipped as a solid as well as a liquid. It is corrosive to tissue and metals. By nature, it is non-toxic and non-volatile and viscous.

Phosphoric acid is mainly used to make fertilizer's phosphate salts. These salts are widely used in various agricultural (as a flavouring agent in animal or poultry feed) and household applications. In dental cement, it is used to prepare albumin derivatives; as an etching solution for cleaning and roughening the teeth surface where dental fillings etc., are to be placed. It is also used in the sugar and textile industries. In food products, it finds application as an acidic food additive, fruit-like flavouring.

It is also used for treating rust and its removal from metal parts, providing metals with resistance against corrosion, and in the process of the phosphate conversion coating. Also, it's used in skin care products to adjust and control the product's pH levels whilst being used in personal care products such as soaps, toothpaste, and detergents which is furthering the market growth. Other applications of the product include its use in phosphoric acid fuel cells; to produce activated carbon; compound semiconductor processing; and in sanitizing brewing and dairy industries.

Phosphoric Acid Production Cost Processes with Cost Analysis

Phosphoric Acid Production from Hemihydrate Process

Phosphoric acid is produced by this process which includes grinding, reaction, filtration and concentration Via Hemihydrate Process.

Details: Germany - based plant Q1 2024 From $ 2499.00 USD

Phosphoric Acid Production from Dihydrate Process

Phosphoric acid is produced by this process which includes grinding, reaction, filtration and concentration.

Details: Germany - based plant Q1 2024 From $ 2499.00 USD

Product Details

| Particulars | Details |

|---|---|

| Product Name | Phosphoric Acid |

| Scope | Manufacturing Process: Process Flow, Material Flow, Material Balance Raw Material and Product Specifications: Raw Material Consumption, Product and Co-product Generation Land and Site Cost: Offsites/Civil Works, Equipment Cost, Auxiliary Equipment Costs, Contingency, Engineering and Consulting Charges, Working Capital Variable Cost: Raw Material, Utilities, Other Variable Costs Fixed Cost: Labor Requirements and Wages, Overhead Expenses, Maintenance Charges, Other Fixed Costs Financing Costs: Interest on Working Capital, Interest on Loans Other Costs: Depreciation Charges, General Sales and Admin Cost |

| Currency | US$ (Data can also be provided in the local currency) |

| Pricing and Purchase Options | Basic: US$ 2499 Premium: US$ 3499 Enterprise: US$ 4799 |

| Customization Scope | The report can be customized as per the requirement of the customer |

| Post-Sale Analysts Report | 10-12 weeks of post-purchase analyst support after report delivery for any queries from the deliverable |

| Delivery Format | PDF and Excel format through email (editable version in PPT/Word format of the report can be also provided on special request) |

Key Questions Answered in This Report

- What are the key requirements for setting up a Phosphoric acid manufacturing plant?

- How is Phosphoric acid manufactured?

- What is the process flow involved in producing Phosphoric acid?

- What are the raw material requirements and costs for producing Phosphoric acid?

- What is the total size of land required for setting up a Phosphoric acid manufacturing plant?

- What are the construction requirements for setting up a Phosphoric acid manufacturing plant?

- What are the machinery requirements for producing Phosphoric acid?

- What are the utility requirements and costs for producing Phosphoric acid?

- What are the manpower requirements for producing Phosphoric acid?

- What are the average salaries/wages of manpower working in a Phosphoric acid manufacturing plant?

- What are the packaging requirements and associated costs for Phosphoric acid?

- What are the transportation requirements and associated costs for Phosphoric acid?

- What are the capital costs for setting up a Phosphoric acid manufacturing plant?

- What are the operating costs for setting up a Phosphoric acid manufacturing plant?

- What should be the price of Phosphoric acid?

- What will be the income and expenditures for a Phosphoric acid manufacturing plant?

FAQs

If you want to change your login details, kindly change from the 'Profile' Section under account details. If you have forgotten your password for any of our products and services kindly click on "Forgot Password' on the login page. Alternatively, you can contact us at: support@procurementresource.com

Need more help?

- We can tailor the report as per your unique requirements such as desired capacity, future expansion plans, product specifications, mode of financing, plant location, etc.

- We can also provide a flexible, easy-to-use, dynamic excel-based cost-model/ dashboard where you can change the inputs to get different outputs

- Speak to our highly skilled team of analysts for insights on the recent trends and innovations, industry best practices, key success and risk factors, product pricing, margins, return on investment, industry standards and regulations, etc.

- Gain an unparalleled competitive advantage in your domain by understanding how to optimize your business operations and maximize profits

- For further assistance, please connect with our analysts