Copolymer Production Cost Reports

Chemicals

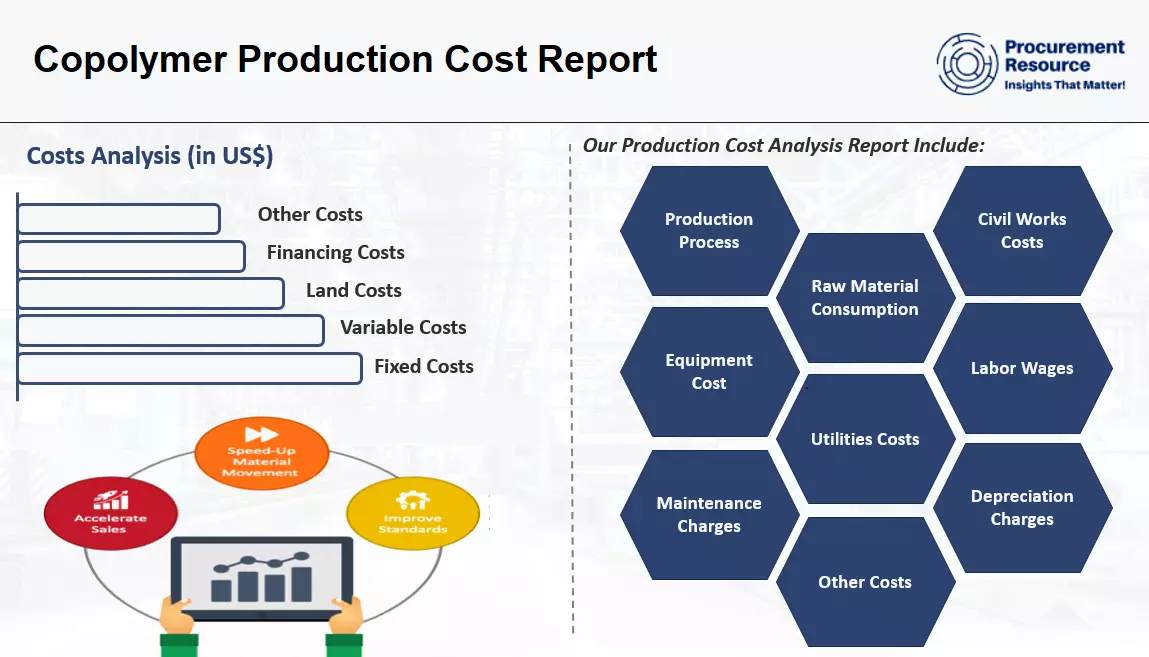

Copolymer production cost report provides a comprehensive analysis and know-how for setting up a Copolymer production plant. The study covers all the requisite aspects that one needs to know for the production of Copolymer. This includes manufacturing processes, raw material requirements, utility requirements, infrastructure requirements, machinery and technology requirements, manpower requirements, packaging requirements, transportation requirements, etc.

Copolymer is a type of polymer comprising two or more distinct repeating units or monomer species; for instance, Lego blocks that contain several acrylonitriles, butadiene, and styrene subunits is a type of copolymer. Most of the commercially significant polymers are copolymers, such as nitrile rubber, polyethene-vinyl acetate (PEVA), and acrylonitrile butadiene styrene (ABS).

Copolymer is formed using multiple species of monomers via copolymerization. They are a diverse class of high molecular weight substances made by chemical combination, typically into long chains, of molecules of two or more simple compounds (monomers that form the polymer). Some types of Copolymers are Butadiene styrene copolymer, nitrile rubber, styrene isoprene styrene etc. They are classified on the basis of their structures. The ones with a single chain are called linear copolymers, while ones containing polymeric side chains are known as branched copolymers.

Copolymers are mainly used for enhancing or modifying some properties of plastics. It is employed in the production of several products, such as tires, plastics, and tubes which drives market growth. They are also used as corrosion inhibitors as well as for improving plastic material's mechanical properties. Copolymers of hygroscopic and hydrophilic polymers usually have applications in drug delivery, cosmetics, and self-polishing paint applications.

Furthermore, Acrylic copolymers find application in the production of personal care products like eyeliners, nail polish, sunscreens, lipsticks, skin lotions, etc. As membranes, Graft polymers can be used for splitting gas and liquids and also in emulsifiers and biomedical applications furthering the market demand.

Spandex, employed as synthetic fibre, is a block copolymer, which is like other block polymers, including polyester and polyamide TPEs that are used in sports goods, hose tubing, and automotive components. Also, Nylon -6-6- is a type of copolymer commonly used for carpeting, in textiles, as well as an engineering material in bearings and gears as it has self-lubricating properties.

Copolymer Production Cost Processes with Cost Analysis

Copolymer Production from an Elastomer and a Vinyl Aromatic Compound

The study offers a detailed cost analysis of Copolymer Production from an Elastomer and a Vinyl Aromatic Compound. In addition, the report incorporates the manufacturing process with detailed process and material flow, operating costs along with financial expenses and depreciation charges.

Details: Germany - based plant Q1 2024 From $ 2499.00 USD

Product Details

| Particulars | Details |

|---|---|

| Product Name | Copolymer |

| Scope | Manufacturing Process: Process Flow, Material Flow, Material Balance Raw Material and Product Specifications: Raw Material Consumption, Product and Co-product Generation Land and Site Cost: Offsites/Civil Works, Equipment Cost, Auxiliary Equipment Costs, Contingency, Engineering and Consulting Charges, Working Capital Variable Cost: Raw Material, Utilities, Other Variable Costs Fixed Cost: Labor Requirements and Wages, Overhead Expenses, Maintenance Charges, Other Fixed Costs Financing Costs: Interest on Working Capital, Interest on Loans Other Costs: Depreciation Charges, General Sales and Admin Cost |

| Currency | US$ (Data can also be provided in the local currency) |

| Pricing and Purchase Options | Basic: US$ 2499 Premium: US$ 3499 Enterprise: US$ 4799 |

| Customization Scope | The report can be customized as per the requirement of the customer |

| Post-Sale Analysts Report | 10-12 weeks of post-purchase analyst support after report delivery for any queries from the deliverable |

| Delivery Format | PDF and Excel format through email (editable version in PPT/Word format of the report can be also provided on special request) |

Key Questions Answered in This Report

- What are the key requirements for setting up a Copolymer manufacturing plant?

- How is Copolymer manufactured?

- What is the process flow involved in producing Copolymer?

- What are the raw material requirements and costs for producing Copolymer?

- What is the total size of land required for setting up a Copolymer manufacturing plant?

- What are the construction requirements for setting up a Copolymer manufacturing plant?

- What are the machinery requirements for producing Copolymer?

- What are the utility requirements and costs for producing Copolymer?

- What are the manpower requirements for producing Copolymer?

- What are the average salaries/wages of manpower working in a Copolymer manufacturing plant?

- What are the packaging requirements and associated costs for Copolymer?

- What are the transportation requirements and associated costs for Copolymer?

- What are the capital costs for setting up a Copolymer manufacturing plant?

- What are the operating costs for setting up a Copolymer manufacturing plant?

- What should be the price of Copolymer?

- What will be the income and expenditures for a Copolymer manufacturing plant?

FAQs

If you want to change your login details, kindly change from the 'Profile' Section under account details. If you have forgotten your password for any of our products and services kindly click on "Forgot Password' on the login page. Alternatively, you can contact us at: support@procurementresource.com

Need more help?

- We can tailor the report as per your unique requirements such as desired capacity, future expansion plans, product specifications, mode of financing, plant location, etc.

- We can also provide a flexible, easy-to-use, dynamic excel-based cost-model/ dashboard where you can change the inputs to get different outputs

- Speak to our highly skilled team of analysts for insights on the recent trends and innovations, industry best practices, key success and risk factors, product pricing, margins, return on investment, industry standards and regulations, etc.

- Gain an unparalleled competitive advantage in your domain by understanding how to optimize your business operations and maximize profits

- For further assistance, please connect with our analysts