Product

Acetylene Price Trend and Forecast

Acetylene Price Trend and Forecast

Acetylene Regional Price Overview

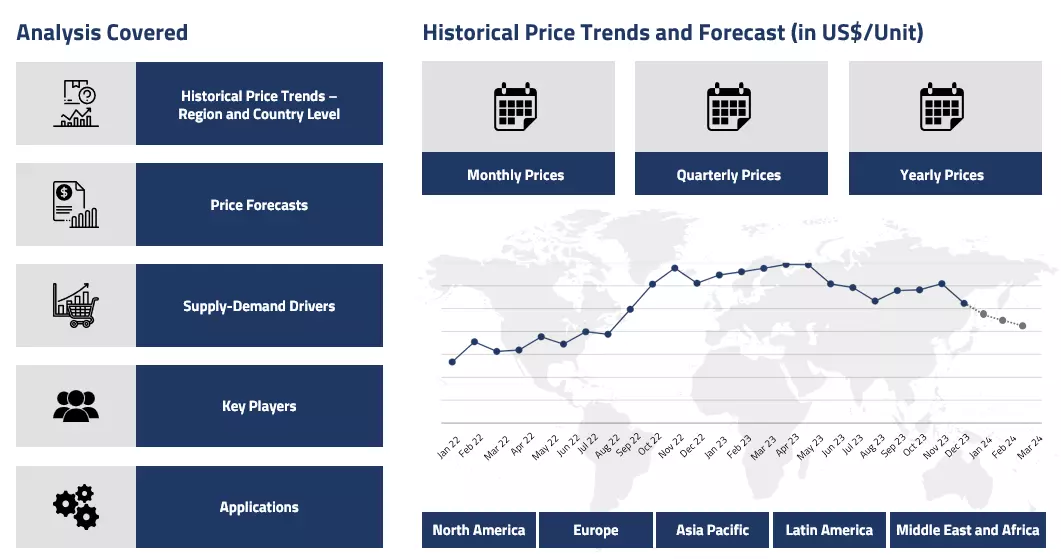

Get the latest insights on price movement and trend analysis of Acetylene in different regions across the world (Asia, Europe, North America, Latin America, and the Middle East & Africa).

Acetylene Price Trend for the Q4 of 2024

Asia

In Asia, acetylene prices demonstrated a bearish trend throughout most of Q4. Chinese production remained robust despite some temporary shutdowns for environmental inspections.

Acetylene Price Chart

Please Login or Subscribe to Access the Acetylene Price Chart Data

Demand from the metal cutting and welding sectors stayed moderate, while the construction industry's seasonal slowdown in winter months further dampened consumption. Southeast Asian markets followed the Chinese price trajectory, though at a slower pace.

Europe

European acetylene markets experienced volatility in Q4, primarily driven by fluctuating natural gas prices and energy costs. The surge in LNG prices due to colder weather impacted production costs significantly. Demand from the automotive and construction sectors remained subdued due to economic uncertainties and seasonal factors. However, the chemical synthesis segment maintained steady offtake.

North America

North American acetylene markets showed resilience in Q4, supported by stable calcium carbide supplies and consistent demand from industrial applications. The region saw improved demand from metal fabrication and chemical synthesis sectors. However, rising energy costs in December, coupled with weather-related disruptions from Hurricane Rafael, caused some supply tightness towards the quarter's end.

Analyst Insight

According to Procurement Resource, the Acetylene market is expected to remain under pressure in early 2025, with potential volatility tied to energy costs and seasonal demand patterns. The incoming Trump administration's energy policies could influence production costs, while growing industrial automation might support demand.

Acetylene Price Trend for the Q3 of 2024

Asia

In the Chinese market, acetylene prices exhibited mixed trends throughout the quarter. Prices followed the downward trajectory of calcium carbide, a key feedstock, and declined sharply due to increased supply, which led to high inventories amid low consumption by downstream industries.

This weakened acetylene’s position in the market. Additionally, downstream demand for acetylene suffered due to the centralized maintenance of PVC manufacturing plants. As a result of these ongoing challenges, market pessimism increased, with fewer new orders and squeezed profit margins.

Europe

The European market mirrored the trend seen in the Chinese market. Acetylene prices fluctuated throughout the quarter as the economy continued recovering from supply disruptions in the previous quarter. Production enterprises struggled with high costs. Additionally, they faced high inventories as downstream procurement maintained a weak outlook. Major demand sectors for acetylene, including construction and automotive, remained troubled due to reduced sales and fewer new orders. Overall, limited upstream cost support and weak downstream demand kept acetylene prices fluctuating throughout the quarter.

North America

In the third quarter of 2024, the price trend of acetylene in the United States mirrored that of its European and Asian counterparts. Acetylene prices were influenced by fluctuations in the natural gas market and developments in the welding industry. With the U.S. presidential election approaching, stable infrastructure investments were observed, signaling positive demand in the downstream welding sector. Additionally, logistical challenges arose due to hurricanes, which are common during this season. Some plants had to shut down production due to disruptions caused by the storms, but the impact was not very severe, and normal supply levels could be restored after a short while.

Analyst Insight

According to Procurement Resource, the prices of acetylene are expected to increase in the near future. Still, they will maintain a fluctuating trend, market projections look optimistic.

Acetylene Price Trend for the Q2 of 2024

Asia

In the second quarter of 2024, the acetylene market in Asia experienced an upward trend driven by increased downstream demand, particularly in China and India. This surge was fueled by a recovering Chinese economy, improvements in the construction sector. In India, strong demand across sectors such as PVC, agrochemicals, retail packaging, automotive, and infrastructure also contributed to the market's upward momentum throughout this quarter.

The rise in coal prices in April led to higher acetylene production costs, yet the overall operating rate increased, ensuring ample supply to meet growing demand. Additionally, the Labor Day holiday intensified procurement activities, further supporting the uptrend of acetylene prices. Additionally, global factors such as rising shipping container rates, fluctuating crude oil prices, and geopolitical tensions in the Middle East influenced the market. A major Taiwanese producer's decision to raise PVC shipment prices and increased inquiries in China and Southeast Asia also contributed a fair share in sustaining the momentum of the market.

Europe

The price trajectory of acetylene in the second quarter of 2024 was influenced by the fluctuations in crude oil prices. Crude oil prices rose due to heightened geopolitical risks in Europe and the Middle East, where ongoing conflicts threaten global oil supply. Ukrainian attacks on Russian oil infrastructure and the potential escalation of the Israel-Hezbollah conflict have contributed to the risk premium in crude futures.

As crude oil is a critical feedstock for acetylene production, these geopolitical and economic factors have led to increased production costs and higher prices for acetylene. The cost support from feedstock calcium carbide amid sustained stable supply chain further contributed to the overall northward movement of acetylene price trend.

North America

In the second quarter of 2024, the price trend of acetylene in the US is heavily influenced by fluctuations in crude oil prices and developments in the welding industry. Rising geopolitical risks, such as Ukrainian attacks on Russian oil infrastructure and potential Middle East conflict has increased crude oil prices, raising acetylene production costs.

On similar grounds, the welding industry experiences robust growth due to infrastructure investments and technological advancements, suggesting positive demand for acetylene. Additionally, the legislative support for infrastructure projects and the increased need for skilled welders further boosted market activity. Consequently, these geopolitical and economic factors have collectively led to higher acetylene prices, with the market remaining sensitive to crude oil price movements and industrial demands.

Analyst Insight

According to Procurement Resource, the price trajectory of Acetylene is expected to sustain in the positive zone in the next quarters as well with the help of extended support from the downstream and feedstock sectors.

Acetylene Price Trend for the Q1 of 2024

| Product | Category | Region | Price | Time Period |

| Acetylene | Chemicals | USA | USD 3300/MT | March 2024 |

| Acetylene | Chemicals | Europe | USD 3400/MT | March 2024 |

Stay updated with the latest Acetylene prices, historical data, and tailored regional analysis

Asia

The Asian acetylene market observed a mixed price trend during the first three months of 2024. The Indian market began firmly with the onset of New Year as the feedstock crude oil prices kept inching higher. In the middle of the quarter, Iraq, one of the most dominant players in OPEC+, confirmed its intention to limit oil output in the coming months because it breached its OPEC+ quota in January.

This reflects how the demand and consumption for petroleum and petroproducts is on the rise. In the Chinese acetylene market, the prices loosened up a little in the second half of the quarter as the demand pressure started to ease down steadily. However, largely positive market sentiment was noticed for the most period since the acetylene price trend showed a strong performance for the majority of said period.

Europe

The ever-rising political and military tensions in the region continued to disturb the overall trading dynamics. Ukraine launched drone attacks on Russian oil refineries, mainly Lukoil Nizhny, Rosneft Ryazan, and Surgut Kirshi, causing partial operational shutdowns.

Consequently, the oil output from the OPEC+ nation tumbled by around 7%, which in turn raised the petrochemical prices in the global markets. As a result of these tribulations in the European markets, the acetylene prices hopped on an inclined trajectory during the said period. The downstream consuming sectors also supported this market behavior. An overall positive performance was experienced.

North America

The North American market behavior for acetylene was not much different from its Asian and European counterparts. The various geopolitical tensions hurdled the industry in the American markets as well. Majorly, the rising armed conflict between Israel and Hamas complicated the trade situation in the US market.

Along with the rising Houthi pirate threats in the Red Sea, they have also disturbed the US market. However, the downstream demands mostly wavered at the lower side, which gave a little reverse push to the acetylene price trend. Overall, a varying price curve was witnessed.

Analyst Insight

According to Procurement Resource, given the current state of geopolitical tensions, the trade situations are likely to trample even more going forward. Acetylene supply crunch is anticipated in the coming months.

Acetylene Price Trend for the October - December of 2023

Asia

The majority of Asian countries struggled with the consistent rise in the level of inventories as the demand for acetylene, along with other petrochemical products, took the route of gradual decline in the fourth quarter of 2023. However, the prices of acetylene in India emerged against the normal trend, and the cost of petrochemicals increased. The domestic producers in India enjoyed the high demand, but it took the traders an entire quarter to utilize the existing inventories, and thus, the market failed to show the expected appreciation in the acetylene price trend.

Europe

Europe's petrochemical industry faces a significant decline as manufacturers struggled with soaring energy prices which was evident in the trajectory of acetylene prices in the fourth quarter of 2023. Due to this substantial decline in manufacturing activities, the consumption of crude oil products in Europe hit a new low. Amid the soaring cost of production, the traders found it more feasible to import acetylene from the US than to produce it domestically, drastically affecting the acetylene price graph movement.

North America

In North America, initially the acetylene prices were stable due to the rise in export activities. However, as the quarter progressed, issues such as drought in the Panama Canal led to a lower number of exports from the nations concerned the traders. In the later stages, the US crude oil prices also depreciated by almost 10%, further hampering the acetylene price trend.

Analyst Insight

According to Procurement Resource, the price trend of Acetylene are likely to fluctuate in the coming quarter, given the current economic scenario and the upset in crude oil prices.

Acetylene Price Trend for the July - September of 2023

Asia

The Asian Acetylene markets observed depreciating price trend during the third quarter of the year 2023. Both key industrial economies, India and China, witnessed a similar fall in the Acetylene price graph. High levels of Acetylene inventory stocks played a pivotal role in these trend.

In China, a slump in downstream demands of Acetylene from the chemical, metallurgical, welding, cutting, and other consuming sectors led to the aggregation of inventories. However, the expansive run of Indian industries in the first half of the year was the reason suppliers ordered more quantities of product to be able to cater to rising demands, but the demands maintained a moderate level during the discussed period. So, the excess stocks created pressure and forced suppliers to discount the commodity prices in order to promote product purchases. Overall, a moderate to cold market response was observed for Acetylene during the said period.

Europe

The inflationary pressure continued to influence the Acetylene market in the European region at the beginning of the third quarter as well. As a result of this, the third quarter had a very disappointing start. However, as suppliers started cutting down on supplies and production quantities, the existing stock quantities became the limiting factor. And even with extant poor demands, the market was able to rise by the end of the third quarter. Overall, mixed market sentiments were observed.

North America

Contrary to the global trend, Acetylene prices in the US market escalated throughout the said period. High production costs, especially because of positive cost support from the feedstock side, guided the Acetylene market sentiments. The general market outlook was upward-looking.

Analyst Insight

According to Procurement Resource, Acetylene prices are likely to continue fluctuating in the coming months as well since various factors are influencing different regional markets.

Acetylene Price Trend for the First Half of 2023

Asia

Acetylene observed mixed price patterns in the first half of 2023 in the Asian market. Prices began with strong positive sentiments in January 2023 and rose steadily for the first couple of months because of good demands from the downstream metallurgical industries. But in the later Q1 Acetylene market suffered as the inventory stocks rose.

Given the high demand, the suppliers started hoarding the products for better profits. To their dismay, the demand subsided, thereby leading to market stockpiles. The suppliers actively participated in destocking. Further, the lowered feedstock prices and improved freight situation caused the prices to decline. Overall, the market fluctuated on a declining trend throughout the remaining months of said period.

Europe

The European Acetylene market kept fluctuating throughout the first half of 2023. Overflowing inventory levels proved detrimental to the market sentiments in the first quarter. Price trend were almost stagnant and showed little wavering on the lower side. But from the onset of the second quarter, demands picked a little pace, and the first half of the second quarter witnessed some short-lived recovery. However, soon the inventories again started dominating the market trend given the strong supply causing the prices to fall towards the end of Q2.

North America

The North American Acetylene market almost replicated the European market behavior in the said period. The market plummeted later in Q1 because of decreased demand from downstream sectors. Production cuts as recovery measures helped a bit at the beginning of Q2, but limited offtakes took over, causing the pricing fundamentals to revert to the lowered wavering trend in later Q2. Overall, mixed market sentiments were observed.

Analyst Insight

According to Procurement Resource, the price trend for Acetylene are expected to continue showcasing mixed price patterns given the current market dynamics. The uncertain demand and rising global inflation will likely impact the acetylene market.

Acetylene Price Trend for the Second Half of 2022

Asia

The price trend for acetylene registered a declining trend in the Chinese domestic market as the prices of feedstock calcium carbide decreased. The price of calcium carbide went from 3900 RMB/MT in July to 3766.67 RMB/MT in September 2022. Also, the upstream crude oil and natural gas prices relaxed providing respite to the petrochemical industry.

With the removal of covid restrictions, factories started operating but the rates were still below the optimum levels, also many plants were under planned shutdowns due to maintenance. The demand from the downstream PVC sector was dismal, hence the supply and demand mismatch led to the acetylene prices falling.

However, the demand improved during the initial few months of the fourth quarter. The upward cost pressure provided much-needed support to the higher prices along with the renewed market demand dynamics. The demand from downstream rubber and food processing industries increased causing the prices to rise. Despite the rise, the prices were still low compared to the values of the initial quarters of 2022.

Europe

The crude oil and natural gas tanked slightly but still far from the desired rates; hence the upstream cost pressure impacted the prices of acetylene. With the high operating costs and muted market transactions, many manufacturers reduced the production levels to only maintain buffer quantities. The reduced market inquiries amid the economic backlash further suppressed buying activity causing the prices to fall.

The prices stabilized momentarily during the start of the fourth quarter as the water levels in the Rhine River (responsible for 80% of the water freight of Germany) began to rise. As transportation and logistics recovered prices decreased. However, soon the rising demand from the downstream sector caused the prices to rise owing to the limited inventories and reduced operating rates.

North America

Acetylene prices fell throughout the US domestic market owing to reduced upstream cost pressure, deserted market transactions, and skilled labour shortages/strikes. The methane futures fell during the said period causing the prices of petrochemicals plus derivatives to decline. The same outlook continued through the fourth quarter. The reduced market inquiries coupled with high operating rates caused the prices to decline.

Analyst Insight

Acetylene prices are likely to incline in the coming months as the international market stabilizes. The rising demand coupled with low inventories and eased logistics will likely affect the prices of acetylene.

Acetylene Price Trend For the Second Quarter of 2022

Asia

The price trend for acetylene were uneven throughout the second quarter of 2022. Due to a lack of inquiries from the construction industry, prices dropped in India during the first half of the said period. The backlog of supplies caused upstream calcium carbide costs to soar in China, which has further depressed the market value of acetylene in India, a country that imports most of its raw materials from China.

The manufacturing costs have increased as a result of the increased spot prices for upstream calcium carbide, thus impacting the benchmark prices for acetylene in the domestic market. Overall, it was seen that the price of acetylene marginally increased at the end of the second quarter.

Europe

Throughout Q2, there had been fluctuations in acetylene prices in Germany. Acetylene prices were restrained by adequate supply and decreasing demand from central Europe. According to the traders, businesses saw a slowdown over time due to backlogged orders, and downstream pipe producers reported battling with weak demand from the construction industry, which put negative cost pressure on price realizations of acetylene in the local market. Moreover, when the second quarter came to a finish, the spot offers for acetylene were under pressure due to the depreciation of the Euro against the US dollar.

North America

In the second quarter of 2022, there was a decline in acetylene pricing patterns. Upstream calcium carbide price offers decreased by over 10%, putting downward cost pressure on acetylene market values in the local market.

Inconsistencies in terminal demand were brought on by the consequences of Russia's invasion of Ukraine. The spot offers for acetylene dramatically decreased toward the end of the second quarter as a result of falling calcium carbide prices and declining downstream PVC demand from the construction industry.

Analyst Insight

Acetylene prices are likely to incline in the coming months as the international market stabilizes. The rising demand coupled with low inventories and eased logistics will likely affect the prices of acetylene.

Acetylene Price Trend For the First Quarter of 2022

Asia

Many businesses focused on specific carbon that had a high added value and performance. Furthermore, the sunrise industries' demand for lithium-ion batteries was expanding, resulting in increased product demand. The majority of manufacturers were expanding their product lines and producing new versions of their existing products.

The Asia calcium carbide market fell in the fourth quarter of 2021 after reaching a new high. Against the solid demand from the downstream PVC manufacturing sector, high charges and restricted availability of freight vessels in the region imposed disproportionate cost support in the exported volumes.

The Chinese authorities' persistent attempts to reduce electricity rationing enhanced the operational loads in the Chinese domestic market. The offers for calcium carbide were settled at 978 USD/MT during the fourth quarter, as a result of the ripple effect. In 2021, China dominated the market in Asia Pacific, thanks to the increased infrastructure and electronics investment, which boosted acetylene black market revenue.

Europe

The demand for acetylene black was driven by an increase in tyre demand in the replacement market around the world. The industry was consolidated, with a few major players controlling a large portion of the worldwide market; as a result, product producers' primary strategy was to develop new items. Throughout the fourth quarter of 2021, the European market for calcium carbide remained positive.

This shift in market sentiment was related to Europe's prolonged energy crisis, which resulted in lower production rates at manufacturing plants. As a result, international prices for mining metals and chemicals were reduced. Due to the increased demand from the downstream industry, calcium carbide prices remained buoyant during the fourth quarter of 2021.

North America

Due to expanded metalworking applications across North America, the metal fabrication industry dominated the global acetylene market. Despite an improvement in the supply-demand imbalance, market sentiment for the raw material, calcium carbide, in the North American region remained depressed throughout the fourth quarter of 2021. This improvement was linked to improved post-hurricane season output rates at manufacturing plants in the United States.

The LME and worldwide markets for mining metals and chemicals, on the other hand, saw large drops. As a result, the offers were constantly dropped, and FOB Midwest (USA) negotiations for calcium carbide powder fell by 7.37% during the quarter, with prices finalised at 1130 USD/MT in December.

Latin America

Acetylene non-tyre specialist applications boosted black market expansion. In 2021, the demand for rubber goods was boosted by rapid urbanisation and industrialization in Asia Pacific and South America.

Acetylene Price Trend For First, Second and Third Quarters of 2021

Asia

During the first quarter of 2021, demand in the Asian market was mild to firm from downstream metal fabrication and BDO manufacturing industries. The overall output of China was temporarily lowered due to Chinese lunar holidays. Several dealers, on the other hand, had already maintained their supplies high in anticipation of the impending shortage. Despite the buildup of advance stocks, acetylene prices in the Asian market surged sharply in February.

In line with this, the Indian market saw a 5.22% increase in dissolved acetylene prices from January to March, with acetylene prices settling at 4265.2 USD/MT in March 2021. Because of the increased demand from downstream sectors, acetylene prices rose significantly in the third quarter of 2021 across the Asia Pacific area.

Limited mining activity in China, combined with government controls to preserve energy, continued to limit raw material calcium carbide exports to a number of countries.

Because calcium carbide is primarily imported in India, downstream acetylene prices rose dramatically in the first half of the year. The issue of power curtailment in the Northern region with the goal of reducing carbon development resulted in a steady increase in calcium carbide pricing in the Chinese domestic market. The increased prices of calcium carbide prompted downstream acetylene manufacturers to adopt a wait-and-see attitude.

Europe

Europe, like other places, had a serious scarcity of acetylene, which is used to make downstream chemicals like BDO and THF. Decreasing imports from the United States contributed to the shortage, since their own regional supply was running low due to lower domestic output. As a result, acetylene prices began to rise. Furthermore, rising shipping container and freight costs effectively pushed up the prices across the region.

In Q3, the European market saw a significant increase in demand for acetylene gas from the industrial gases category, but it struggled to import enough gas to close the gap. In July, acetylene prices increased by a factor of ten. The market trend for the rest of 2021 was dominated by rising feedstock carbide prices and robust demand from the building sector. Larger price rises for construction and auto repair helped maintain its demand.

North America

Acetylene manufacturing in North America is typically reliant on the availability of LNG throughout the region. Approximately 7.4% of the total LNG output was affected as a result of the terrible winter storm, resulting in a critical shortage in the region. Meanwhile, downstream BDO (Butanediol) demand remained strong, driving up the prices during the quarter. Major regional players also raised their rates for acetylene cylinders, contributing to the total increase in export prices.

Despite the uncertainty created by the second wave in Q2, the market in North America remained stable, with significant demand for acetylene from a variety of end-use sectors. Following the industrial rebound caused by the winter storm, there was an increase in the chemical’s pricing in Q3, as several downstream manufacturers increased their production. During the third quarter, downstream acetylene makers increased their demand for calcium carbide in the North American market.

Acetylene Price Trend For the Year 2020

Asia

Although Asian acetylene sales improved from Q2 to Q3, they remained below the pre-COVID levels. Higher margins due to a shortage of raw materials somewhat compensated for the producer's margin drop. Construction activity recovered from deep reductions in the previous quarter, resulting in resilient demand for oxyacetylene cylinders. Major plant turnarounds heard at several Chinese acetylene-based PVC factories, on the other hand, put strain on demand patterns, resulting in limited offtakes and muted offers across the area.

Europe

The COVID-19 pandemic had a substantial impact on the European acetylene demand in Q2 and Q3, with a significant drop in in-person trading. Limited requirements were heard for metal cutting and construction projects while the majority of the people stayed at home due to the pandemic-induced slump. Western Europe, where the lockdown had been lengthier and more severe than in Central,

Eastern, and Northern Europe, saw a significant reduction in demand. However, demand for oxyacetylene from civil infrastructure remained strong in eastern Europe. As the largest producers declared maintenance turnarounds by the end of the third quarter to balance their stockpiles, certain supply limitations emerged.

North America

During the third quarter of 2020, the demand in the Americas remained subdued. The production disruptions induced by Hurricane Laura continued to hamper operations at BASF's petrochemical plant in Geismar, Louisiana, which had a minor impact on overall profits. The company's Geismar Acetylene plant had an annual production capacity of 130 MT.

The industrial gas sector in the United States had a mixed quarter-on-quarter performance, owing to a gradual shift in demand for medicinal gases including oxygen and carbon dioxide. Demand for dissolved acetylene and other industrial gases, on the other hand, remained muted due to lower welding hardgoods sales.

Procurement Resource provides latest prices of Acetylene. Each price database is tied to a user-friendly graphing tool dating back to 2014, which provides a range of functionalities: configuration of price series over user defined time period; comparison of product movements across countries; customisation of price currencies and unit; extraction of price data as excel files to be used offline.

About Acetylene

Acetylene, also known as ethyne, is the simplest and most well-known member of the hydrocarbon series composed of one or more pairs of carbon atoms joined by triple bonds. This series is referred to as the acetylenic series, or alkynes. It is a colourless, flammable gas that is widely utilised as a fuel in oxyacetylene welding and metal cutting processes, as well as a raw ingredient in the synthesis of a wide variety of organic compounds and plastics.

Acetylene Product Details

| Report Features | Details |

| Product Name | Acetylene |

| Industrial Uses | Glass Industry, Production of solvents and alkenes, Flame scarfing, Metallurgical heating and hardening, Welding, Cutting |

| Chemical Formula | C2H2 |

| Synonyms | Ethyne, Narcylene |

| Molecular Weight | 26.03 g/mol |

| Supplier Database | BASF SE, Gulf Cryo, Linde, Praxair Technology Inc., SINOPEC, Chengdu Xinju Chemical Co. Ltd. |

| Region/Countries Covered | Asia Pacific: China, India, Indonesia, Pakistan, Bangladesh, Japan, Philippines, Vietnam, Iran, Thailand, South Korea, Iraq, Saudi Arabia, Malaysia, Nepal, Taiwan, Sri Lanka, UAE, Israel, Hongkong, Singapore, Oman, Kuwait, Qatar, Australia, and New Zealand Europe: Germany, France, United Kingdom, Italy, Spain, Russia, Turkey, Netherlands, Poland, Sweden, Belgium, Austria, Ireland Switzerland, Norway, Denmark, Romania, Finland, Czech Republic, Portugal and Greece North America: United States and Canada Latin America: Brazil, Mexico, Argentina, Columbia, Chile, Ecuador, and Peru Africa: South Africa, Nigeria, Egypt, Algeria, Morocco |

| Currency | US$ (Data can also be provided in local currency) |

| Supplier Database Availability | Yes |

| Customization Scope | The report can be customized as per the requirements of the customer |

| Post-Sale Analyst Support | 360-degree analyst support after report delivery |

Note: Our supplier search experts can assist your procurement teams in compiling and validating a list of suppliers indicating they have products, services, and capabilities that meet your company's needs.

Acetylene Production Processes

- Production of Acetylene from Methane; and from Coal

Acetylene is produced by partial combustion, electric arc, or high temperature regeneration processes from gaseous hydrocarbons like methane or liquid hydrocarbons (e.g., petroleum products). After that, acetylene is removed from the resulting gas mixture.

Methodology

The displayed pricing data is derived through weighted average purchase price, including contract and spot transactions at the specified locations unless otherwise stated. The information provided comes from the compilation and processing of commercial data officially reported for each nation (i.e. government agencies, external trade bodies, and industry publications).

Assistance from Experts

Procurement Resource is a one-stop solution for businesses aiming at the best industry insights and market evaluation in the arena of procurement. Our team of market leaders covers all the facets of procurement strategies with its holistic industry reports, extensive production cost and pre-feasibility insights, and price trends dynamics impacting the cost trajectories of the plethora of products encompassing various industries. With the best analysis of the market trends and comprehensive consulting in light of the best strategic footstep, Procurement Resource got all that it takes.

Client's Satisfaction

Procurement Resource has made a mark for itself in terms of its rigorous assistance to its clientele. Our experienced panel of experts leave no stone unturned in ensuring the expertise at every step of our clients' strategic procurement journey. Our prompt assistance, prudential analysis, and pragmatic tactics considering the best procurement move for industries are all that sets us apart. We at Procurement Resource value our clients, which our clients vouch for.

Assured Quality

Expertise, judiciousness, and expedience are the crucial aspects of our modus operandi at Procurement Resource. Quality is non-negotiable, and we don't compromise on that. Our best-in-class solutions, elaborative consulting substantiated by exhaustive evaluation, and fool-proof reports have led us to come this far, making us the ‘numero uno' in the domain of procurement. Be it exclusive qualitative research or assiduous quantitative research methodologies, our high quality of work is what our clients swear by.

Related News

Table Of Contents

Our Clients

Get in Touch With Us

UNITED STATES

Phone:+1 307 363 1045

INDIA

Phone: +91 8850629517

UNITED KINGDOM

Phone: +44 7537 171117

Email: sales@procurementresource.com