Product

Butanal Price Trend and Forecast

Butanal Price Trend and Forecast

Butanal Regional Price Overview

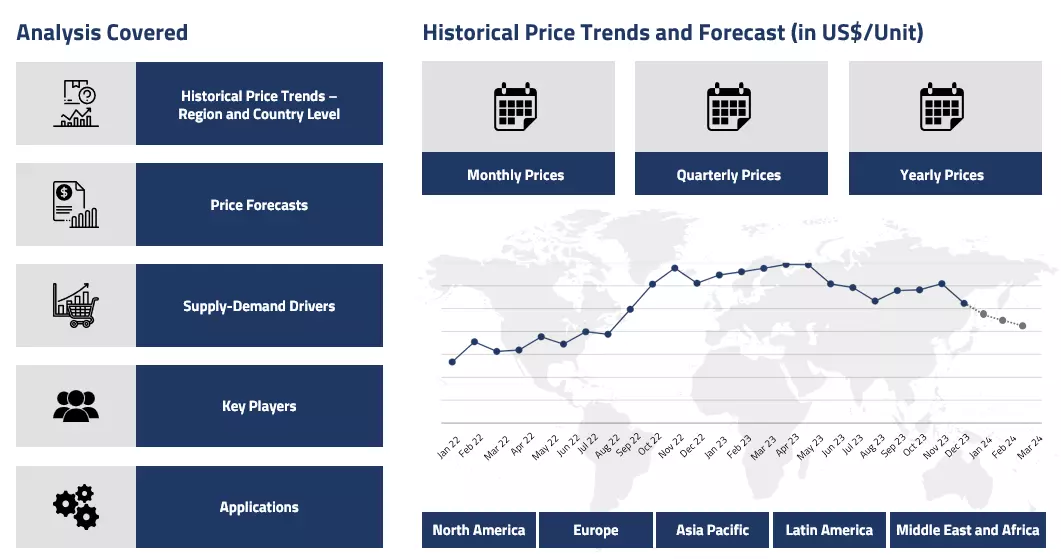

Get the latest insights on price movement and trend analysis of Butanal in different regions across the world (Asia, Europe, North America, Latin America, and the Middle East & Africa).

Butanal Price Trend for Q1 of 2025

Asia

During the first quarter of 2025, the butanal market in Asia was soft and volatile, driven largely by the propylene market. Sluggish demand from the downstream industries, especially the plastics and automotive sectors, placed pressures on prices. Meanwhile, propylene availability was high because of new plant operations in Asia, leading to an oversupply condition.

Butanal Price Chart

Please Login or Subscribe to Access the Butanal Price Chart Data

This surplus supply also held back price hikes. At the beginning of the quarter, a short-term peak in demand, especially from the winter season, gave temporary support to the market, but this did not hold. At the end of the quarter, weak demand from major downstream industries and poor raw material prices kept the market weak, with no decisive upward direction in prices.

Europe

The butanal market in Europe was relatively stable but weak throughout the first quarter of 2025. Sufficient inventories and a benign winter limited energy demand below forecast levels, hence impacting poor industrial demand. This limited economic activity throughout Europe, combined with lower production from downstream markets like resins and polyether, meant poor buying interest for butanal.

Though logistics problems at times slowed imports, total supply was consistent, and the higher euro made imports cheaper, taking some of the pressure off domestic prices. Nevertheless, with all these forces, there was no significant enough impetus to drive prices higher, and the market remained conservative as producers and consumers adapted to the soft demand climate.

North America

Butanal market in North America witnessed volatility during the first quarter of 2025. The early effect of harsh winter weather brought about a short-term price increase due to rising demand for heat, but this was succeeded by supply tightening due to increased export activity.

The pressure on infrastructure compounded the problems, maintaining the market tightness. When winter demand fell off, production rebounded, but stocks remained tight as a result of ongoing high export volumes. Sluggish demand from downstream sectors such as polyether held back any major price recovery. The market did begin to stabilise towards the close of the quarter, but volatility still impacted prices.

Analyst Insight

According to Procurement Resource, butanal market will face a balance between demand and supply but may have price fluctuations caused by raw material prices and logistical issues in the near future.

Butanal Price Trend for the Year 2024

Asia

In Asia, especially India, the butanal market witnessed upward trajectory throughout the year. Initially, prices remained more or less stable with supply and demand conditions offsetting each other. However, as the year progressed, some disruption occurred due to fluctuations in the price of propylene, the major feedstock for butanal production. This caused a gradual increase in the price of butanal as the year progressed, due to tightening of availability of feedstocks and higher production costs.

Furthermore, domestic demand from downstream industries, including those for plastic production during the latter half of the year, supported these price increases. Towards the end of the year, the Indian butanal price trend eased a bit as the upstream propylene market declined.

Europe

In Europe, the butanal price trend was marked by mixed price movements during the year 2024. In the early half of the year, the market observed subdued activity as producers were adapting to the market situation, and there were minimal noteworthy movements in the pricing.

Nonetheless, as the year went on, there was a sharp jump in price levels. This was fueled by combination of reasons, primarily elevated freight costs due to disruptions across key shipping corridors such as the Red Sea. These supply chain constraints imposed tight conditions, leading to a surge in butanal prices. Following this steep increase, the market settled as producers adjusted to the new pricing conditions and demand normalized.

North America

The North American butanal market witnessed a fluctuating price trend throughout 2024. In the first part of the year experienced relatively flat prices, with little movement. But as disruptions in the Red Sea caused freight expenses to increase, the region experienced a steep rise in butanal prices. This disruption was exacerbated by supply chain problems, which impacted the cost structure of downstream products.

Following this peak, the market stabilized somewhat, and prices started to stabilize as the international market got used to the increased logistics costs. In the last quarter of the year, the prices started to decline, indicating a slump in the upstream propylene market, which put pressure on the prices of butanal downwards.

Analyst Insight

According to Procurement Resource, the butanal markets will likely experience some volatility in prices at the beginning of the year. But with stable supply chains and a normal correction in freight rates, the market will likely stabilize during Q1’25.

Butanal Price Trend for the Second Half of 2023

Asia

The butanal market exhibited a very mixed performance during the second half of 2023. The third quarter performed better than the fourth quarter, with internal variations within in region as the Chinese market performed better than the Indian market for butanal.

The edge both Indian and Chinese petrochemical industries had with access to cheap Russian oil was steadily vanishing; thus, the prices inclined marginally in the third quarter. However, as the inventory stocks started dominating in the fourth quarter, the prices started to slide in the Asian markets. The observed market fluctuations were, however, confined within narrow ranges. Overall, mixed market sentiments were witnessed.

Europe

The European butanal market was observed to be following its Chinese counterpart during the said period; the prices fluctuated within close limits here as well. Influenced by the fluctuations in the feedstock propylene prices and the demands from the downstream coating and pharma industries, the price trend was more inclined in the third quarter compared to the fourth quarter. Given the long holiday season and disturbances in international trade during the fourth quarter, the prices were observed to be constantly sliding during this time.

North America

In the American butanal market, the prices started slow at the beginning of the third quarter in July’23. With supportive inventories and dull demands, the price graph initially tottered at low levels; however, as time progressed and the product movement increased, the prices rose in the later months of Q3. However, the market momentum again took a reverse gear in the fourth quarter as the prices started to fall again because of a tepid demand trajectory. Overall, dull market behavior was witnessed.

Analyst Insight

According to Procurement Resource, the Butanal price trends are expected to vary in the coming months as well. Since the demands are likely to remain weak, not much improvement is anticipated in the price trend.

Butanal Price Trend for the First Half of 2023

Asia

The butanal market exhibited mixed sentiments; prices mostly wavered on the lower side in the first half of 2023. Market demand from the downstream adhesive, pharma, and agrochemical industries remained dull, especially in the Chinese market. Inventories were already high amidst low trade activities in the post-lockdown revival phase of Chinese industries.

So high supplies and dull demands kept the market prices down for Butanal. Indian market had a good start with stable supply–demand dynamics, but a dip in demand in the later H1 pulled the prices down. Overall low swinging price trend for Butanal were observed.

Europe

European market mimicked the Chinese market sentiments and remained riddled with little to no inquiries from sellers and the downstream markets. The availability of cheap Asian imports and high inventory stocks were the major reasons behind falling price trend. Overall, prices hovered on the lower side.

North America

North American Butanal market behaved no differently than other global markets during the said period. Limited offtakes from the downstream industries kept the demands very low, and available stocks were more than enough to cater to them. So, discounts had to be offered for destocking to give space to new purchases. Market sentiments remained dull.

Analyst Insight

According to the Procurement Resource, the Butanal prices are expected to continue similar bearish market trend as the growth in downstream demand is vital to improving the Butanal market’s fundamentals, but current market projections make it look very unlikely.

Butanal Price Trend for the Second Half of 2022

Asia

The price trend for Butanal exhibited mixed price patterns in the Asia-Pacific region during the second half of 2022. Given the lowered price of feedstock propylene and bearish demands from the downstream oxo-alcohol industries, the butanal prices fell during the initial months of Q3. However, soon the demand from allied sectors improved, providing the much-needed respite to the butanal prices.

The same upward trend continued in Q4, given the rising demand from the paints and coating sector. However, soon the market turned bearish, and price trend declined as the inventory level rose; the manufacturers were forced to lower their quotations in order to remain competitive.

Europe

The European region witnessed the direct consequences of the Russia-Ukraine war. The acute energy crisis triggered a cost-of-living crisis, thereby contracting the purchasing capacity and demand of the consumers. The prices declined initially but soon stabilized towards the end of Q3. The same upward trend continued in Q4 as the demand from oxo-alcohol markets increased. However, the demand was short-lived, and prices plunged again as the disbalance between the market dynamics kept widening, given the uncertainties.

North America

The US domestic market mimicked the global trend in terms of butanal pricing. After occasional fluctuations in the Q3, the prices finally plunged in the fourth quarter. The weak cost pressure from feedstock propylene, low product movement, and bearish demands from oxo-alcohol and paint sectors negatively influenced the price trend for Butanal.

Butanal Price Trend For the Second Quarter of 2022

Asia

The price of butanal remained unstable in Q2 of 2022. But as of the first quarter of 2022, the price increased by over 10%. Except for India and China, the majority of Asian nations were buying crude oil from OPEC. Petrochemical prices in the area were unstable as a result.

The price of petrochemicals was affected by the volatility of upstream naphtha and feed propylene costs after inflation as well as Russian crude oil imports. The fluctuating cost of oil also affected the price of fuel and freight. Phthalate was in high demand from the oxo alcohols industries at the beginning of the quarter but gradually decreased toward the end, and offtakes remained moderate in Quarter 2.

Europe

The price trend for butanal was similar throughout the quarter, and prices increased steadily throughout the European region. The price of propylene, a petrochemical feedstock, spiked at the start of Q2, greatly raising the cost of producing the good. The prices of the feedstock propylene and upstream naphtha steadied in the middle of the quarter.

butanal costs remained on the higher side and the product's price increased moderately until the end of the quarter as a result of the region's firm energy and gas costs brought on by gas supply difficulties. With average product offtakes from the local market, the demand from downstream Oxo-alcohol makers remained low.

North America

In the North American region, butanal prices continued to increase during the quarter. High petrochemical costs in the first half of the quarter sharply increased feed Propylene costs, which in turn drove up butanal production costs in the area. However, by the middle of the quarter, feed costs had steadied, and until the end of the quarter, butanal costs had only slightly increased.

Due to higher orders from regional automakers, which decreased until the end of Q2 due to lower automobile sales, the demand from oxy-alcohol industries remained strong from the phthalate producer, and product offtakes were steady throughout Q2 from the domestic market.

Butanal Price Trend For the First Quarter of 2022

Asia

Butanal prices in Asia rose by 14.9 percent in India and 7.8 percent in Japan in the first quarter of 2022, compared to the final quarter of 2021. In January, price in Japan was 2440 USD/MT FOB Tokyo, and by the end of March, it had risen to 2520 USD/MT FOB Tokyo.

Because the Philippines is a significant supplier of butanal, the continuing war between Russia and Ukraine resulted in a rise in freight charges, which resulted in an increase in pricing. Butyraldehyde prices rose as demand from the downstream sector surged, particularly in food additives where it is employed as a flavouring ingredient and for aroma.

North America

Because of rising demand from downstream food firms in baked products, frozen dairy, and alcoholic drinks, butanal prices in North America increased to 2335 USD/MT FOB New York in the first quarter of 2022. Depleting supplies and stockpiles drove up the cost of producing propylene and n-butanol, which pushed up the price of butanal.

Transportation and manufacturing expansion influenced demand predictions, and crude oil market attitudes swung changes in economic fundamentals considerably. Because of the restrictions on large enterprises between Russia and the United States as a result of the ongoing war situation, which impacted North American value chains and resulted in increased energy costs, the United States saw a spike in the Oxo alcohol market.

Europe

Butanal prices grew 4.9 percent in the first quarter of 2022 on the European continent, compared to the final quarter of 2021 in Germany. By the conclusion of the first quarter, butanal prices in Germany were hovering around 2146-2289 USD/MT FOB Hamburg. The cost of propylene and butyryl chloride, which are derivatives of crude petroleum, has been impacted by the price of butanal. Because of its rising demand in the downstream food market as oxo alcohol and efficiency, European businesses have developed a rhodium-based method for the production of butanal, which is somewhat more expensive.

Butanal Price Trend For the Fourth Quarter of 2021

Asia

Due to decreasing arbitrage profits from US LPG imports, the North-East Asian area has seen a progressive change in cracking capacity, with naphtha outperforming propane as the favoured feedstock.

Although China's propane dehydrogenation capacity has grown over the years, there has been a trend reversal in the last three to four quarters as the country becomes more import-dependent for LPG, losing out in the arbitrage market as imports from the United States and the Middle East become insufficient for domestic consumption. Propylene import costs were marginally higher in Q4, with average CFR prices of 1020 USD/MT compared to 1010 USD/MT in Q3.

North America

Throughout Q4 of FY21, the North American market saw remarkable trend consistency. While downstream market trend were essentially inelastic for refinery grade propylene, polymer grade propylene market prices moved in lockstep with downstream polypropylene prices. Following a supply-short third quarter in which refinery output was affected and supply networks along the Gulf Coast were disrupted by hurricanes, the early half of Q4 remained a seller's market.

The pattern shifted in the second half of Q4, with feedstock naphtha and LPG prices beginning to decline in the first week of November and continuing to fall until the end of December. The average prices of propylene refinery and polymer grades were assessed at 520 USD/MT FAS Houston and 1640 USD/MT FOB Houston, respectively (down 5% from the Q3 average). Butanal prices were impacted in a similar manner.

Europe

During the fourth quarter, European markets saw a steady shift in imports from regional markets to Asian propylene due to increased arbitrage margins. The average price of the chemical sourced from domestic trade was estimated at 1245 USD/MT on an FD Hamburg basis, while import prices from North-East Asia were estimated at 1135 USD/MT on a CIF Hamburg basis.

Butanal Price Trend For First, Second and Third Quarters of 2021

Asia

During the first quarter, the supply of propylene in Asia remained balanced, thanks to the inclusion of new facilities in China, followed by the restart of key facilities in South Korea, including LG Chem. After a turnaround, Yeochun NCC (YNCC) began operations in the second part of Q1 2021 and announced an expansion of its Ethylene and Propylene facility.

As the arbitrage between the European and North American regions emerged, Asian producers moved their stockpiles to meet western demand for higher revenue. Throughout the quarter, demand in Asia increased as a result of improved downstream offtakes. In mid-February, propylene CFR China prices surpassed 1000 USD/MT.

Butanal prices were range bound as demand for downstream Polypropylene increased, while supply remained plentiful in the third quarter. With the start of GS Caltex's new steam cracker facility in Yeosu on July 5th, the region's propylene supply increased. Another steam cracker facility, with a capacity of roughly 410 KTPA, added to the basics of supply. However, propylene prices in the domestic market continued to fall, accompanied by reduced demand in numerous regions of Asia as a result of additional delta variant instances.

Due to the drop in market activity caused by covid infections, negotiations for downstream Polypropylene remained limited in China. In India, too, ample supply combined with strong demand drove butanal prices down from 1175 USD/MT to 1158 USD/MT during the quarter.

North America

During the first quarter of 2021, the chemical’s supplies in the region were limited, limiting margins in the downstream derivatives market, resulting in an increase in demand as some petrochemicals production units shut down in the US Gulf region due to severe freeze weather.

Major facilities such as LyondellBasell and INEOS olefins shut down in mid-February due to harsh weather, resulting in a multi-fold increase in propylene costs in the United States. Domestic propylene (PGP) prices soared to an all-time high of 1950 USD/MT in mid-February.

During the third quarter of 2021, the general market prognosis for the feedstock in North America improved. Leading firms such as ExxonMobil and Dow Chemicals in Baton Rouge, Louisiana, and Taft, Louisiana, respectively, began production in the second week of September after storm Ida shut down several plants. In Q3 2021, the NOVA and Enterprise propylene crackers were reported to be offline.

Polypropylene trended upwards due to the considerable demand draw, thus suppliers focused on increasing stocks as demand from downstream industries remained strong during the quarter. According to industry analysts, storm Ida caused a 5-8 percent decline in propylene supplies. In September, the US Gulf propylene price was estimated to be 1850 USD/MT. Butanal prices followed a similar trend.

Europe

Throughout Q1, the European region's propylene supply remained limited as a result of lower refinery production due to the continuing pandemic and closure limitations. The situation became much worse when a major supplier announced a scheduled reversal in early February. Nonetheless, demand remained steady throughout the quarter.

Due to the terrible weather conditions in the United States, the trend of exports switched from the United States to Asian providers. Europe remains the most affordable continent in terms of costs. In the third quarter of 2021, the supply of propylene in Europe increased, owing to the recovery of PDH plants, crackers, and refineries.

The downstream sectors' demand expanded steadily during the quarter. Prices in Germany continued to rise, eventually settling at 1305 USD/MT FD. In Q3 2021, Hamburg saw a considerable price increase in its upstream.

Butanal Price Trend For the Year 2020

Asia

By the end of Q3, the supply of feedstock propylene had tightened across Asia, with pricing talks increasingly starting up, notably in northeast Asia. Fluid catalytic cracking (FCC) and steam cracking Naphtha facilities in Japan had been hit by a number of scheduled and unforeseen outages. Export cargo availability was limited due to strong local demand in South Korea. In July, two Propane Dehydrogenation (PDH) plants with a combined nameplate capacity of 1050 KTPA were commissioned in China, showing that demand was more or less steady.

North America

The protracted closure of BASF Total's Port Arthur cracker in Texas impacted regional propylene supplies. Due to lower gasoline demand, America's combined refinery run rate was kept at 75-80 percent due to the pandemic-induced lockdown, further reducing Propylene output. Hurricane Laura triggered a series of force majeure declarations, causing a brief interruption in regional supplies. As industrial activity steadily improved during the quarter, propylene prices in the US Gulf increased amid production concerns and outlook turning optimistic.

Europe

Due to the unstable economic conditions, butanal prices were settled in a limited range in the third quarter, with the demand forecast mostly mixed-to-low. Unexpected cracker turnarounds in early August hampered the product's timely supply, but they were remedied by the first half of September.

The continuous outage at Borealis' Stenungsund, Sweden cracker added to the product availability shortage. The pricing graph last exhibited a rising tendency in July, when it was estimated to be about 780 USD/MT FD NWE, before tapering off at the end of the quarter.

Procurement Resource provides latest prices of Butanal. Each price database is tied to a user-friendly graphing tool dating back to 2014, which provides a range of functionalities: configuration of price series over user defined time period; comparison of product movements across countries; customisation of price currencies and unit; extraction of price data as excel files to be used offline.

About Butanal

Butyraldehyde, often known as butanal, is an organic molecule that is a butane aldehyde derivative. It belongs to a group of botanicals made up of propane with a formyl substituent at the 1-position. This substance is a colourless, flammable liquid with a foul odour. Most organic solvents are soluble in butanal. It oxidises to generate butyric acid with extended contact to air.

Butanal Product Details

| Report Features | Details |

| Product Name | Butanal |

| Industrial Uses | Paints and Coatings, Pharmaceutical, Agrochemical, Polymer |

| Chemical Formula | C4H8O |

| Synonyms | Butyraldehyde, n-butyraldehyde, Butyral |

| Molecular Weight | 72.11g/mol |

| Supplier Database | Mitsubishi Chemical Corporation, Tokyo Chemical Industry Co., Ltd., KH Neochem Co. Ltd, Eastman Chemical Company, BASF SE |

| Region/Countries Covered | Asia Pacific: China, India, Indonesia, Pakistan, Bangladesh, Japan, Philippines, Vietnam, Iran, Thailand, South Korea, Iraq, Saudi Arabia, Malaysia, Nepal, Taiwan, Sri Lanka, UAE, Israel, Hongkong, Singapore, Oman, Kuwait, Qatar, Australia, and New Zealand Europe: Germany, France, United Kingdom, Italy, Spain, Russia, Turkey, Netherlands, Poland, Sweden, Belgium, Austria, Ireland Switzerland, Norway, Denmark, Romania, Finland, Czech Republic, Portugal and Greece North America: United States and Canada Latin America: Brazil, Mexico, Argentina, Columbia, Chile, Ecuador, and Peru Africa: South Africa, Nigeria, Egypt, Algeria, Morocco |

| Currency | US$ (Data can also be provided in local currency) |

| Supplier Database Availability | Yes |

| Customization Scope | The report can be customized as per the requirements of the customer |

| Post-Sale Analyst Support | 360-degree analyst support after report delivery |

Note: Our supplier search experts can assist your procurement teams in compiling and validating a list of suppliers indicating they have products, services, and capabilities that meet your company's needs.

Butanal Production Processes

- Production of Butanal from Propylene

Propylene combines with an aqueous solution of rhodium catalyst to generate aldehyde in this method.

Methodology

The displayed pricing data is derived through weighted average purchase price, including contract and spot transactions at the specified locations unless otherwise stated. The information provided comes from the compilation and processing of commercial data officially reported for each nation (i.e. government agencies, external trade bodies, and industry publications).

Assistance from Experts

Procurement Resource is a one-stop solution for businesses aiming at the best industry insights and market evaluation in the arena of procurement. Our team of market leaders covers all the facets of procurement strategies with its holistic industry reports, extensive production cost and pre-feasibility insights, and price trends dynamics impacting the cost trajectories of the plethora of products encompassing various industries. With the best analysis of the market trends and comprehensive consulting in light of the best strategic footstep, Procurement Resource got all that it takes.

Client's Satisfaction

Procurement Resource has made a mark for itself in terms of its rigorous assistance to its clientele. Our experienced panel of experts leave no stone unturned in ensuring the expertise at every step of our clients' strategic procurement journey. Our prompt assistance, prudential analysis, and pragmatic tactics considering the best procurement move for industries are all that sets us apart. We at Procurement Resource value our clients, which our clients vouch for.

Assured Quality

Expertise, judiciousness, and expedience are the crucial aspects of our modus operandi at Procurement Resource. Quality is non-negotiable, and we don't compromise on that. Our best-in-class solutions, elaborative consulting substantiated by exhaustive evaluation, and fool-proof reports have led us to come this far, making us the ‘numero uno' in the domain of procurement. Be it exclusive qualitative research or assiduous quantitative research methodologies, our high quality of work is what our clients swear by.

Table Of Contents

Our Clients

Get in Touch With Us

UNITED STATES

Phone:+1 307 363 1045

INDIA

Phone: +91 8850629517

UNITED KINGDOM

Phone: +44 7537 171117

Email: sales@procurementresource.com