Product

Dimethyl Terephthalate Price Trend and Forecast

Dimethyl Terephthalate Price Trend and Forecast

Dimethyl Terephthalate Regional Price Overview

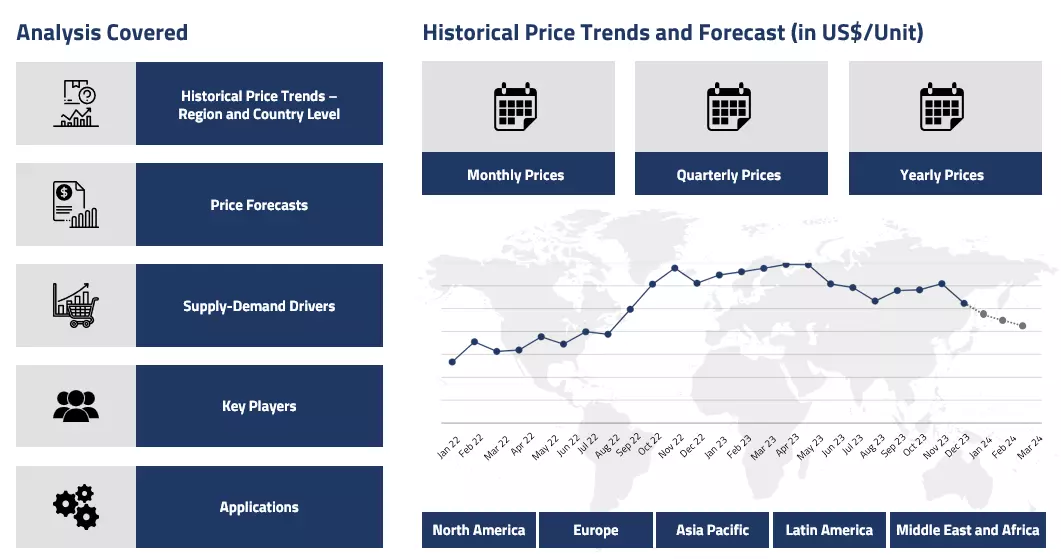

Get the latest insights on price movement and trend analysis of Dimethyl Terephthalate in different regions across the world (Asia, Europe, North America, Latin America, and the Middle East & Africa).

Dimethyl Terephthalate (DMT) Price Trend for the Year 2024

Asia

In Asia, DMT prices exhibited a fluctuating pattern throughout 2024. The first quarter saw a slight uptick driven by increased feedstock costs and moderate demand from polyester producers. By Q2, prices stabilized as production capacities improved and supply chains normalized. However, the third quarter experienced downward pressure due to weak downstream demand and oversupply, particularly in China.

Dimethyl Terephthalate Price Chart

Please Login or Subscribe to Access the Dimethyl Terephthalate Price Chart Data

Chinese manufacturers reduced production rates in response to sluggish consumer demand and rising inventory levels. The final quarter continued this bearish trend with prices dropping further as imports from other regions increased and domestic consumption remained subdued.

Europe

European DMT markets displayed a more stable trajectory in 2024. The year began with firm prices supported by tight supply and higher energy costs. During the second quarter, prices marginally increased as production constraints persisted and demand from the packaging sector remained steady.

The third quarter witnessed a slight decline as feedstock costs eased and imports from Asia increased. By Q4, the market softened further with prices trending downward due to weakening demand from downstream industries and economic uncertainties, particularly in Germany and Belgium where industrial activity slowed.

North America

North American Dimethyl Terephthalate market experienced mixed trends throughout 2024. The first quarter saw elevated prices driven by supply constraints and increased production costs. Production disruptions caused by adverse weather conditions in the early months tightened supply significantly. By mid-year, prices stabilized as supply improved and demand remained consistent. The third quarter showed a gradual decline as feedstock costs decreased and imports from Asia increased. The final quarter continued this downward trajectory with prices dropping further due to softening demand from key end-use sectors and ample supply.

Analyst Insight

According to Procurement Resource, DMT prices are expected to remain under pressure in early 2025 due to ongoing oversupply and weak demand fundamentals. However, potential feedstock cost increases and production rationalizations might provide some support to prices in the later months.

Dimethyl Terephthalate Price Trend for the Second Half of 2023

Asia

During the second half of 2023, dimethyl terephthalate prices in China experienced a slight decline, gradually in the third quarter but steeply in the fourth quarter of 2023. However, the stability in the market during the third quarter was supported by the consistent demand from the PET plastic industry.

But the other market fundamentals such as cost support from the feedstock industries and sluggish development of the Asian industrial sector, particularly in the fourth quarter, exerted a negative influence on the pricing patterns of dimethyl terephthalate.

Europe

Throughout the latter half of 2023, the European dimethyl terephthalate market correlated closely with the pricing movements of terephthalic acid, a feedstock for dimethyl terephthalate production. The decline in terephthalic acid and crude oil prices during Q3 and Q4 contributed to the downfall of dimethyl terephthalate prices. Further, factors such as negative consumer sentiment and inflation pressure, along with disruptions in the Red Sea route due to the ongoing Israel-Hamas crisis, had a significant impact on exports, further leading to inventory rises and supporting the downward spiral of dimethyl terephthalate price trend.

North America

In the US domestic market, dimethyl terephthalate price trends followed the same trajectory as paved by the slowdown seen in Europe. The sharp decline in domestic crude oil prices and disruptions in overseas orders due to drought-like conditions in the Panama Canal during late 2023 significantly contributed to the downward trend in the dimethyl terephthalate market. The persistent downgrading of economic parameters and strict lending policies adopted by the banks also limited the growth rate of the dimethyl terephthalate price trend.

Analyst Insight

According to Procurement Resource, the price trend of Dimethyl terephthalate is expected to face the ill consequences of depreciating consumer sentiments and global trade disruptions.

Dimethyl Terephthalate Price Trend for the First Half of 2023

Asia

Dimethyl Terephthalate is made from its feedstock, xylene, so the price trend for both these align very closely. As the Chinese industries had been working at their full pace after a long pandemic shutdown, the downstream demands from PET, PBT, packaging, automotive, electronics, etc., industries were high. So, the prices inclined for most of the said period of the first six months, with some reverse fluctuations in the second quarter. Overall, the market sentiments were observed to be mixed.

Europe

In the European Dimethyl Terephthalate market, inventory levels and existing demands determined the market behavior. Dimethyl Terephthalate price trend fluctuated throughout the discussed period. The prices fluctuated positively during the initial months of the first quarter and then declined till the middle of the second quarter as the stocks started piling up. The latter half of the second quarter again witnessed an inclination in the price curve.

North America

The prices started slowly at the beginning of the first quarter and inclined for the majority period. However, some fluctuations were observed at the end of both quarters. But demands were fairly stable throughout, and the overall market sentiments were also comparatively positive.

Analyst Insight

According to Procurement Resource, with given steadiness in the demand spectrum, the Dimethyl Terephthalate price trend are expected to continue oscillating in a narrow range in the upcoming months.

Dimethyl Terephthalate Price Trend for the Year 2022

Asia Pacific

The prices of dimethyl terephthalate are dependent on the market sentiments of its feedstock material i.e., paraxylene. In the first quarter of 2022, the prices inclined exponentially as crude oil prices increased given the tensions between Russia and Ukraine. The demand from the end-user industries also increased due to ample supply and high demand to counter it. In the second quarter, the upward trajectory was maintained due to weak supply and high demand from the downstream derivative market.

The third quarter, however, did not follow the same trajectory. The demand became stagnant while the supply rose leading to a rise in the level of inventories. The adverse weather conditions in the region further aided the low prices. The prices returned to their previous levels in the fourth quarter initially but declined due to low consumer confidence and high uncertainties in the market demand.

Europe

The feedstock p-xylene market, rose in the first two quarters as crude oil prices soared due to strong demand and weak supply owing to the Russia-Ukraine war. This also increased the production cost and with increased offtakes, the price trend in the region increased.

Another reason for the incline was high freight charges and difficulties in trade due to port congestion activities. The prices, however, plunged in the fourth quarter as the inventory levels rose and the demand from the end-user industries remained stagnant. The prices improved marginally in the last quarter, only to decline in the subsequent months due to weak market conditions.

North America

The price trend for dimethyl terephthalate remained on the negative side throughout 2022. In the first quarter, the price trend were adversely affected by the disruptions caused by the ongoing war between Russia and Ukraine and the retaliatory Western sanctions against Russian exports. In the third and fourth quarters of 2022, the price trend suffered from weak global economic conditions, sluggish demand, and soaring inflation rates in the region. These factors contributed to keeping the price trend for dimethyl terephthalate in the negative zone.

Analyst Insight

According to Procurement Resource, the prices of dimethyl terephthalate are expected to fluctuate in the upcoming months as the price trend will be affected by high demand, weak economic conditions, and uncertain operational costs.

Dimethyl Terephthalate Price Trend For the Fourth Quarter of 2021

Asia

In October 2021, dimethyl terephthalate prices rose sharply due to rising demand from the domestic market and low output levels throughout the market. For paraxylene, one of key raw materials of DMT, India relied significantly on imports from China and other far East Asian nations. Ex-Ahmedabad, paraxylene costs were estimated to be 137770 INR/MT.

Due to a downturn in demand in the domestic market, PX market sentiment weakened in the second half of Q4. Demand from the Purified Terephthalic Acid (PTA) market bolstered the upstream PX market in China, but as the quarter progressed, market sentiment worsened. This affected dimethyl terephthalate prices as well.

Europe

Upstream PX manufacturers had high profits during the fourth quarter thanks to a healthy PET market. As a result of the heightened market activity, strong bullish prices for paraxylene emerged. On FOB basis, dimethyl terephthalate prices climbed from 925 USD/MT in October to 1055 USD/MT in December 2021. Throughout the quarter, energy input costs remained high, pushing up overall production costs and resulting in significant price increases for DMT.

North America

The North American paraxylene market started the fourth quarter on a high note, thanks to rising demand for PTA, a precursor for PET bottles. PX prices in the United States surged to 989 USD/MT FOB Texas in October, but demand degradation in the second half of the year significantly impacted market sentiment, and prices fell to 865 USD/MT in December. Traditional consumption decline in lieu of the winter holiday season contributed to the drop in demand.

Dimethyl Terephthalate Price Trend For First, Second and Third Quarters of 2021

Asia

Due to restricted spot availability of upstream products and various plant shutdowns recorded in the region during the Chinese Lunar New Year holidays, supplies of the feedstock paraxylene were tight in the Asia Pacific during Q1 2021, resulting in a total loss of 480,000 tonnes of output.

In March, numerous companies including Sinopec (East China), Zhejiang Petrochemical, Sinopec Yangtze, CNPC Sichuan, and others were temporarily offline, contributing to inventory constraints and raising offers. In March, dimethyl terephthalate prices in China increased by 23.9% on a month-over-month basis, to 173 USD/MT, due to a worldwide supply deficit. The market's mood was boosted by strong demand for Chinese PX from the United States.

On the strength of growing demand from downstream manufacturers, the APAC paraxylene market saw moderate recovery in the third quarter of 2021. After a period of continuous weekly reductions in August, prices began to rise in September. In September, Sinopec refineries in China reduced throughputs in response to 'dual cutbacks' in energy consumption and carbon emissions in several areas, such as Jiangsu province in eastern China.

The province's Sinopec Jinling Petrochemicals cut its run rates by around three percentage points in August, affecting PX prices in the region during Q3. After the ease in pandemic cases in India, there has been a small rebound followed by a comeback in economic operations. In September, the ex-Mumbai price of paraxylene was estimated to be 1685 USD/MT.

Europe

During the first quarter of 2021, supplies in the European region were limited due to decreased operating rates of refineries in the northwest European region due to cold weather conditions, followed by a fall in imports from the United States, which further constrained market supply.

Offtakes from the downstream PTA industry boosted demand. Some market players were hopeful that product fundamentals had improved in the previous year and that the bullishness would endure at least through H1 2021. During the third quarter of 2021, the general market forecast for paraxylene in Europe was viewed as tight. After experiencing logistical challenges early in the quarter, supply fundamentals improved as imports from Asia lessened.

OB Hamburg offers declined from 900 USD/MT in July to 890 USD/MT in September, indicating a downward trend in Germany. In Q3, the downstream PTA industry experienced a rise in demand.

North America

The North American paraxylene supply remained tight in the first quarter of 2021, owing to production interruptions induced by the arctic freeze that slammed the US gulf region, suspending 73 percent of the region's total paraxylene capacity and resulting in worldwide supply constraints. Due to the lack of paraxylene, demand from the downstream PTA and PET industries soared. Dimethyl terephthalate prices increased dramatically in the North American, with April delivery prices estimated to be about 895 USD/MT, up 205 USD/MT from February delivery rates.

In the third quarter of 2021, the general demand picture in the North American domestic market remained unclear. The majority of production was shut down throughout the first part of the quarter, although several critical ports and waterways reopened in the first week of September after Hurricane Ida hit the US Gulf coast, causing massive damage and power disruptions.

Despite the suspension in raw material production, the supply of paraxylene remained stable. Given the high input volumes from the packaging sector in the wake of the US economic recovery, downstream PTA demand was strong in Q3. During the third quarter, feedstock prices were estimated to be 940-980 USD/MT FOB Texas.

Dimethyl Terephthalate Price Trend For the Year 2020

Asia

Because of the planned maintenance turnarounds at various PTA factories, demand for the Asian paraxylene steadily declined due to dull offtakes for the derivative PTA. Due to the weak production margins observed by end-use sectors, manufacturers were heard operating at a lower pace than the previous quarter.

In the quarter ending September 2020, the resumption of operations at some factories in the manufacturing hub China, such as Dongying Weilian Chemical and Sinopec Hainan, added to the pressure on the market fundamentals of paraxylene.

North America

Due to an unforeseen outage in one refinery followed by a maintenance turnaround in another refinery, market sentiment for the raw material remained positive. The scarcity of aluminum boosted demand for PET bottles and containers, boosting demand for paraxylene. However, a sudden scarcity of the co-feedstock MEG for PET manufacturing, along with a series of extended turnarounds conducted in the wake of Hurricane Laura, produced a backlog in PET production, decreasing paraxylene profit margins.

Europe

In Q3 2020, the market for paraxylene was dull due to abundant supply and depressed demand in the area due to weakening PTA. The vendors had little room to extend their profit margins due to plentiful product inventories. Few European companies were observed adopting output cutbacks to help the lingering fundamentals, but it was clearly insufficient to lift emotions. Spot operations were severely limited due to low regional demand, as purchasers were hesitant to acquire large volumes due to the current demand uncertainties.

Procurement Resource provides latest prices of Dimethyl Terephthalate. Each price database is tied to a user-friendly graphing tool dating back to 2014, which provides a range of functionalities: configuration of price series over user defined time period; comparison of product movements across countries; customisation of price currencies and unit; extraction of price data as excel files to be used offline.

About Dimethyl Terephthalate

The chemical compound dimethyl terephthalate is a diester made up of terephthalic acid and methanol. It's a white solid that melts into a colourless liquid that may be distilled.

Dimethyl Terephthalate Product Details

| Report Features | Details |

| Product Name | Dimethyl Terephthalate |

| Industrial Uses | Polyethylene Terephthalate (PET), Polybutylene Terephthalate (PBT), Packaging, Electrical & Electronics, Automotive |

| Chemical Formula | C15H16O2 |

| Synonyms | Bisphenol A, 80-05-7, 2,2-Bis(4-hydroxyphenyl)propane, 4,4'-Isopropylidenediphenol |

| Molecular Weight | 228.29 g/mol |

| Supplier Database | SASA Polyester Sanayi A, SK Chemicals co. ltd, Eastman Chemical Company, Fiber Intermediate Products Co., JSC Mogilevkhimvolokno |

| Region/Countries Covered | Asia Pacific: China, India, Indonesia, Pakistan, Bangladesh, Japan, Philippines, Vietnam, Iran, Thailand, South Korea, Iraq, Saudi Arabia, Malaysia, Nepal, Taiwan, Sri Lanka, UAE, Israel, Hongkong, Singapore, Oman, Kuwait, Qatar, Australia, and New Zealand Europe: Germany, France, United Kingdom, Italy, Spain, Russia, Turkey, Netherlands, Poland, Sweden, Belgium, Austria, Ireland Switzerland, Norway, Denmark, Romania, Finland, Czech Republic, Portugal and Greece North America: United States and Canada Latin America: Brazil, Mexico, Argentina, Columbia, Chile, Ecuador, and Peru Africa: South Africa, Nigeria, Egypt, Algeria, Morocco |

| Currency | US$ (Data can also be provided in local currency) |

| Supplier Database Availability | Yes |

| Customization Scope | The report can be customized as per the requirements of the customer |

| Post-Sale Analyst Support | 360-degree analyst support after report delivery |

Note: Our supplier search experts can assist your procurement teams in compiling and validating a list of suppliers indicating they have products, services, and capabilities that meet your company's needs.

Dimethyl Terephthalate Production Process

- Dimethyl Terephthalate Production from Toluene and Methanol

The disproportionation procedure is the method used to make DMT. ExxonMobil PxMax is comparable. As an intermediate, p-xylene is produced. After that, P-xylene is oxidised, combined with methanol, and lastly esterified to form DMT.

Methodology

The displayed pricing data is derived through weighted average purchase price, including contract and spot transactions at the specified locations unless otherwise stated. The information provided comes from the compilation and processing of commercial data officially reported for each nation (i.e. government agencies, external trade bodies, and industry publications).

Assistance from Experts

Procurement Resource is a one-stop solution for businesses aiming at the best industry insights and market evaluation in the arena of procurement. Our team of market leaders covers all the facets of procurement strategies with its holistic industry reports, extensive production cost and pre-feasibility insights, and price trends dynamics impacting the cost trajectories of the plethora of products encompassing various industries. With the best analysis of the market trends and comprehensive consulting in light of the best strategic footstep, Procurement Resource got all that it takes.

Client's Satisfaction

Procurement Resource has made a mark for itself in terms of its rigorous assistance to its clientele. Our experienced panel of experts leave no stone unturned in ensuring the expertise at every step of our clients' strategic procurement journey. Our prompt assistance, prudential analysis, and pragmatic tactics considering the best procurement move for industries are all that sets us apart. We at Procurement Resource value our clients, which our clients vouch for.

Assured Quality

Expertise, judiciousness, and expedience are the crucial aspects of our modus operandi at Procurement Resource. Quality is non-negotiable, and we don't compromise on that. Our best-in-class solutions, elaborative consulting substantiated by exhaustive evaluation, and fool-proof reports have led us to come this far, making us the ‘numero uno' in the domain of procurement. Be it exclusive qualitative research or assiduous quantitative research methodologies, our high quality of work is what our clients swear by.

Table Of Contents

Our Clients

Get in Touch With Us

UNITED STATES

Phone:+1 307 363 1045

INDIA

Phone: +91 8850629517

UNITED KINGDOM

Phone: +44 7537 171117

Email: sales@procurementresource.com