Product

Hexamethylene Diisocyanate Price Trend and Forecast

Hexamethylene Diisocyanate Price Trend and Forecast

Hexamethylene Diisocyanate Regional Price Overview

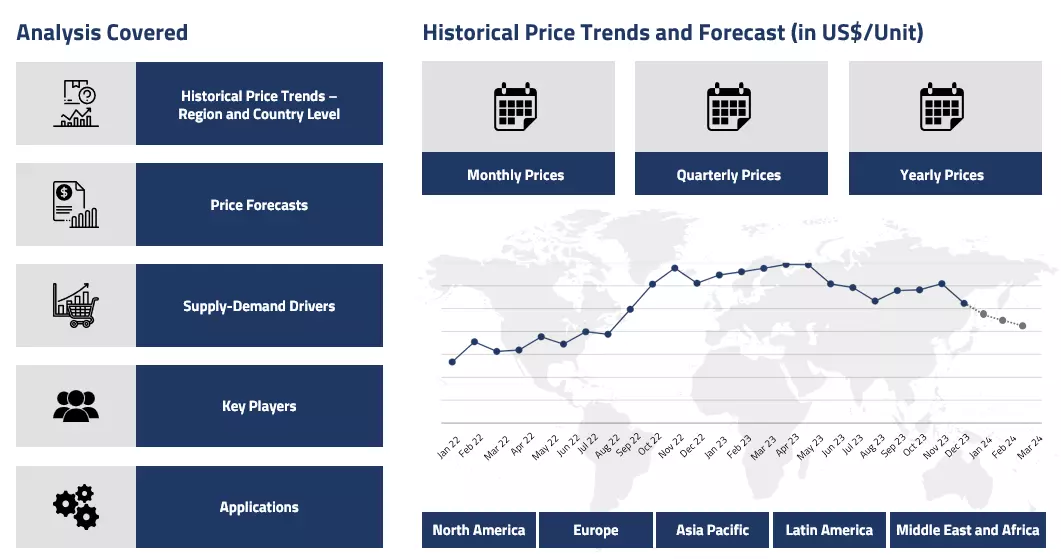

Get the latest insights on price movement and trend analysis of Hexamethylene Diisocyanate in different regions across the world (Asia, Europe, North America, Latin America, and the Middle East & Africa).

Hexamethylene Diisocyanate (HDI) Price Trend for the First Half of 2025

Asia

HDI prices in the Asia-Pacific region showed a mixed trend throughout the first half of 2025. In Q1, prices rose in January due to steady production and better feedstock supply. However, weak demand in automotive and construction, especially in China, led to a price drop in February.

Hexamethylene Diisocyanate Price Chart

Please Login or Subscribe to Access the Hexamethylene Diisocyanate Price Chart Data

After the Lunar New Year, stockpiles increased, keeping prices under pressure. In Q2, demand remained moderate in Southeast Asia, but China’s sluggish recovery and subdued property sector kept overall consumption low. Supply remained stable, but market sentiment stayed cautious due to inconsistent end-use sector performance.

Europe

In Europe, HDI prices were highly volatile in H1’25. Q1 began with a price surge due to limited raw material availability, geopolitical risks, and weather-related energy strain. But mid-quarter saw sharp declines as labor strikes, port congestion, and external trade tensions disrupted logistics.

In March, recovery began as production stabilized and demand from the automotive sector, especially EVs, picked up. In Q2, strong downstream demand from polyurethane applications in construction and automotive helped prices rebound further. However, supply chain issues, including port delays and rerouted shipments, kept supply tight and contributed to firm pricing.

North America

North American HDI prices showed a generally bullish trend in H1’25. Q1 faced weather-related production issues and shipping delays, but strong demand from automotive and construction industries supported pricing. In Q2, consistent offtakes and growing interest in electric vehicles continued to push demand. Although feedstock costs were relatively stable, freight and operational challenges added to the pricing pressure, keeping the market firm.

Analyst Insight

According to Procurement Resource, HDI prices are likely to stay elevated in early Q3’25, supported by healthy demand from polyurethane applications and tighter supply conditions globally.

Hexamethylene Diisocyanate (HDI) Price Trend for Q4 of 2024

Asia

During the fourth quarter of 2024, the HDI market in the Asia-Pacific region showed weaker performance compared to the previous quarter. Although production levels stayed steady and feedstock availability was sufficient, overall demand was mixed.

The automotive sector supported consumption thanks to stable vehicle production, but the construction industry struggled due to inflation, limited investments, and reduced housing activity. Export activity grew but faced hurdles such as trade delays and international tariffs, which affected trade flow. As a result, the market lacked strong momentum, and prices remained under pressure throughout the quarter.

Europe

In Europe, HDI prices dropped sharply in Q4’24, driven mainly by subdued demand across multiple industries. The construction sector remained especially weak due to economic uncertainty and a fall in housing activity, while the automotive segment lost strength towards the end of the quarter.

Inventories rose due to poor offtake, and production costs fluctuated because of changing crude oil prices and early-quarter raw material shortages. Even though crude supply issues eased later, port congestion and slowing exports continued to weigh on the market. As a result, the region recorded a significant quarter-on-quarter price drop.

North America

The North American HDI market also experienced a decline in Q4’24. Despite stable production, the construction and furniture sectors showed limited demand, contributing to a buildup in stock. Slower orders from polyurethane producers added to the weak market tone.

Export activity was lower due to reduced overseas demand, while feedstock costs came down due to falling crude oil prices, adding further downward pressure. Although the automotive industry maintained steady demand, it wasn't enough to offset broader weakness in other sectors.

Analyst Insight

According to Procurement Resource, the HDI market is expected to remain cautious, with recovery tied closely to improvements in construction and export performance across all major regions.

Hexamethylene Diisocyanate Price Trend for Q3 of 2024

Asia

The market for hexamethylene diisocyanate (HDI) in Asia experienced significant price volatility. Prices were heavily influenced by fluctuations in feedstock costs, as well as the broader instability in crude oil prices. Tight supply in some key manufacturing regions, combined with periodic production challenges, led to short-term price increases. However, these were tempered by weaker downstream demand from sectors like automotive, coatings, and construction, where consumption remained subdued.

The result was a market characterized by periodic price hikes followed by corrections as demand remained inconsistent. The outlook for HDI prices in Asia suggests continued volatility, driven by supply chain disruptions and raw material price fluctuations.

Europe

In Europe, the HDI market also saw considerable price fluctuations in Q3'24. As in Asia, the rising cost of feedstocks, exerted upward pressure on HDI prices. Geopolitical tensions and volatility in the crude oil market further complicated price trends, leading to frequent price adjustments by producers. Demand from key industries like automotive and construction was weak, which prevented prices from sustaining the highs observed during certain periods of the quarter. As a result, the European market was volatile, with prices oscillating in response to both cost increases and the lack of substantial demand recovery. Given the current economic uncertainties, this volatility is likely to continue in the short term.

North America

North America experienced similar fluctuations in HDI prices during Q3’24. Rising feedstock prices, combined with supply constraints, initially pushed prices upward. However, these price increases were offset by sluggish demand from industries such as coatings and automotive, which are sensitive to broader economic conditions. The petrochemical sector's challenges, compounded by the ongoing volatility in crude oil prices, kept the market unstable. Producers adjusted prices throughout the quarter to reflect these changing conditions, leading to oscillations in the HDI market.

Analyst Insight

According to Procurement Resource, the price of Hexamethylene Diisocyanate is likely to remain volatile given the rising feedstock costs, geopolitical factors, and weaker downstream demand.

Hexamethylene Diisocyanate Price Trend for Q2 of 2024

Asia

Hexamethylene Diisocyanate is a crucial compound used primarily in the polyurethane and adhesive industries. Since both HMDA (Hexamethylenediamine) and chlorine act as feedstock materials for its production, the price trend depends heavily on their market latitudes. During the second quarter of the year 2024, the Asian Hexamethylene Diisocyanate markets showcased frequent fluctuations throughout the entire span.

The quarter had a dull start, pertaining to a higher carryover from the previous months, which led to an overflow of inventories. This exerted a downward pressure on the Hexamethylene Diisocyanate's price trend. Concurrently, the demands from the downstream industries also kept the markets struggling. For China, the decline in international orders also affected the pricing outlooks. Some occasional corrections mid-quarter propelled the prices slightly, however, the overall market trajectory remained downward wavering. The downfall in crude oil prices also elevated the cost pressure for Asian Hexamethylene Diisocyanate markets.

Europe

Influenced by the depreciation in Asian markets the Hexamethylene Diisocyanate prices did not show much enthusiasm in the European markets as well. HDI-based polyurethanes are widely used in automotive, aerospace, and construction industries for protective coatings and finishes. However, a dip in purchase queries from these sectors dampened the suppliers' interest in Hexamethylene Diisocyanate markets. In Europe, regional trade was already struggling because of the logistical disruptions and supply chain curtailments. Moreover, this decline in the demand curve subdued the market fundamentals. Besides some occasional variation, the price trend for Hexamethylene Diisocyanate remained sublimated throughout the entire span.

North America

In the American markets, the Hexamethylene Diisocyanate prices were found to oscillate throughout the said time period. The said quarter had a firm start as the supply and demand equation supported the pricing outlook initially. The downstream polyurethane and adhesive sectors kept the demand trajectory stable. However, as time progressed, consumer demands started to decline in the American markets, especially in the construction sector. Therefore, the price graph took a mild downturn around the latter months of the quarter. Overall, mixed market sentiments were witnessed.

Analyst Insight

According to Procurement Resource, Hexamethylene Diisocyanate prices are expected to vary going forward; current supply and demand dynamics suggest buoyancy in the global markets.

Hexamethylene Diisocyanate Price Trend for Q1 of 2024

Asia

Hexamethylene Diisocyanate, or HDMI, is directly produced from Hexamethylene Diamine (HDMA), which is generally sourced from cyclohexane or cyclohexene. So, because of the close association in the production and consumption of these chemicals their price trends also align closely with one another. During the first quarter of the year 2024, the Asian hexamethylene diisocyanate market was largely stable and consolidated since the gap between the supply and demand outlooks sustained for the majority of the said period. The majority of the upliftment came from the upstream costs.

The escalation in crude oil prices in the said quarter raised the manufacturing and processing rates; this was reflected directly in commodity prices. However, despite this surge, the downstream demands remained largely subdued. The adhesive and coating sectors were not able to provide any significant support. So, with this bidirectional push and pull, the prices wavered within the same positions at the price index. The price trend was very short ranged and bound during the said period for hexamethylene diisocyanate.

Europe

In the European hexamethylene diisocyanate market, the prices were observed to vary over the discussed span of the first three months of the year. Initially, the market sentiments were still positive as the construction sector was still able to attract consumer’s interest. The New Year and Christmas holidays called for an increment in housing and renovation activities, thus the hexamethylene diisocyanate demands rose in the early phase.

The manufacturing costs were already heavily inclined and were already pushing the market up for hexamethylene diisocyanate. In the later phase of the quarter, the demands did dwindle a little bit, but the overall market performance was still optimistic for the most part. A moderate price trajectory was observed for hexamethylene diisocyanate during Q1’24 in Europe.

North America

The American hexamethylene diisocyanate market was found to be exhibiting similarities with the Asian market during the said period. The prices were wavering within confined boundaries here as well. The market outlook was more or less balanced in a similar manner. The inclining crude oil and energy prices did motivate suppliers to raise their quotations. The market demands remained steady amidst all this. Suppliers expected better results, but the achieved neutral marker performance was also bearable for hexamethylene diisocyanate.

Analyst Insight

According to Procurement Resource, the Hexamethylene Diisocyanate price trends are expected to continue the soft run in the coming months since the demand dynamics are not likely to alter much going forward.

Hexamethylene Diisocyanate (HDI) Price Trend for Q4 (October - December) of 2023

Asia

The hexamethylene diisocyanate price trend wavered in close proximity during the final quarter of the year 2023. Since hexamethylene diisocyanate is extensively used in the paint, coating, adhesives, and polyurethane industries, the market trend were directly proportional to the performance of these downstream sectors.

Demands from these markets could not help the HDI market much during the given time frame as the market offtakes dwelled on the lower side during the year-end period. A substantial decline in crude oil prices also plunged the raw material costs for hexamethylene diisocyanate, giving the market another pushback.

Europe

The global recession in crude oil prices was replicated in the hexamethylene diisocyanate prices in the European markets. The cut down in global trade activities because of freight disturbances also pushed the market trend backward. An underwhelming market performance was witnessed as the prices vacillated around the lower side of the price graph.

North America

The North American market trend for hexamethylene diisocyanate were no different from the Asian and European markets. The market was observed to be witnessing abatement during the last three months of the year 2023. Downward spiraling price trend were observed during the fourth quarter of 2023.

Analyst Insight

According to Procurement Resource, the existing Hexamethylene Diisocyanate inventory stocks project the continuation of similar market patterns in the coming months as prices are expected to vacillate in a narrow range.

Hexamethylene Diisocyanate Price Trend for Q3 (July - September) of 2023

Asia

In the Asia Pacific region, the hexamethylene diisocyanate price trend registered a bearish tone throughout the third quarter of 2023. The demand for hexamethylene diisocyanate not only from the domestic but also from the international industries remained muted during this phase.

On the supply side, the production rates also suffered from the limited availability of raw materials. There was some relief in the consistent decline in the hexamethylene diisocyanate prices during the month of September when the downstream fertilizer sector improved its procurement rates.

Europe

In the third quarter of 2023, the bearish sentiments of the hexamethylene diisocyanate prices were a direct consequence of the poor momentum of European markets. The downstream industries suffered from the cautious purchasing activities of consumers during the holiday season. Further, the declining condition of the European economy also altered the trajectory of the hexamethylene diisocyanate price graph during the third quarter. In addition to this, the competitiveness in the market was enhanced by the influx of cheap imports from Asian countries, forcing the traders to lower their price quotations.

North America

The initial half of the third quarter witnessed a gradual decline in the hexamethylene diisocyanate price trend as industrial activities slumped in the North American region. The excess availability of the stocks and muted demand for hexamethylene diisocyanate negatively affected its prices during this phase. But, during the second half of this quarter, the supply chains got disrupted due to low levels of water in the majority of North American rivers, stabilizing the supply-demand equilibria. In addition to this, the pressure of inflation also eased out, increasing the purchasing potential of consumers.

Analyst Insight

According to Procurement Resource, the price trend of Hexamethylene Diisocyanate are estimated to follow an inclining trajectory as the demand seems to be improving in the upcoming quarters.

Hexamethylene Diisocyanate Price Trend for the First Half of 2023

Asia

The first half of the year 2023 witnessed a fluctuating price trend for hexamethylene diisocyanate. The market trend started on a positive note at the beginning of the first quarter as the downstream foam industries posed consistent demands. And since the international supply chains were disrupted because of the war in Europe, the upstream costs rose consistently, attributed to the heightening of crude oil and energy prices. However, as quarter two arrived, many industries already succumbed to the inflationary pressure and had ceased production temporarily or permanently.

This led to a sudden backtracking of downstream demands, and also the inventory levels had already risen to the levels which were very easily capable of catering to the existing demands. So, with the rising trend in Q1’23 and market depreciation in Q2’23, the overall market outlook was mixed.

Europe

The European markets were suffering the most because of the war going on in its backyard. Given the costs of living crisis, the expenditure in the region totally became necessity-centric, which resulted in the hexamethylene diisocyanate market facing demand depreciation. Suppliers cut down on production in order to prevent further losses. Overall, muted market sentiments were observed.

North America

Just like the Asian market, the hexamethylene diisocyanate prices exhibited sluggish price trend for most of the discussed period after starting positively in the first half of the first quarter of 2023. Economic inflation remained the key determining factor throughout the said time. Overall, sliding price patterns were observed.

Analyst Insight

According to Procurement Resource, Hexamethylene Diisocyanate prices are likely to exhibit mixed price trend in the coming months, given the current demand variations in the global markets.

Hexamethylene Diisocyanate Price Trend for Second, Third, and Fourth Quarter of 2022

Asia

The last three quarters of the year 2022 experienced mixed market behavior for hexamethylene diisocyanate in the Asian region. In the Chinese market, the haunting memories and effects of the COVID-19 lockdown were still very fresh. With the skepticism and uncertainty around the lockdown situation, the suppliers were still hesitant to restart industries.

So, as a result, the price graph of the second quarter for hexamethylene diisocyanate showed almost negligible movement. However, things started to change for the better by the beginning of the third quarter. The industries started opening up at a slow pace. This resulted in a steady comeback of market queries for hexamethylene diisocyanate. The second half of the year 2022 was still better in this regard. Overall, varied market sentiments were observed.

Europe

The hexamethylene diisocyanate price trend were mostly escalating throughout the said period. Most of the forward push in the hexamethylene diisocyanate price index was coming from the mountainous inflation inflicted upon the entire region because of Russia’s armed invasion of Ukraine. Because of sudden leaps in energy prices, everything got costlier. The discussed span of time witnessed severe economic tribulations in the European region.

North America

Just like Europe, the American market also faced the wrath of high global inflation rates as the market prices for hexamethylene diisocyanate kept wavering at the high end of the price curve.

Analyst Insight

According to Procurement Resource, Hexamethylene Diisocyanate prices are likely to fluctuate as per market demands and the economic situations of different regions.

Hexamethylene Diisocyanate Price Trend for First Quarter of 2022

Asia

Due to severe Covid 19 regulations and the return of the virus in numerous Asian nations in late February, feedstock liquid chlorine prices fell in the APAC area. Manufacturing cost increased in Q1 due to disruption in production activities under the Zero covid policy. However, Covid's revival in Asian countries resulted in only a few inquiries from the home market. In the month of January, demand for the goods was lower than predicted.

Furthermore, some chemical manufacturing enterprises in China, such as Shanghai, experienced shutdowns and output cuts, resulting in a decrease in the price of chlorine, impacting hexamethylene diisocyanate prices as well. In India, the price was evaluated at 158 USD/MT in March.

Europe

Due to suspended manufacturing and disturbed supply as a result of the Russia-Ukraine war, the price of liquid chlorine increased in the European market. In late March, the European market experienced a supply deficit of chlorine due to various production decreases. Due to decreased material availability, manufacturers were forced to adjust their offers.

Furthermore, demand for primary chlorine-consuming PVC remained robust in the European market, contributing to price increases. In the month of March, liquid chlorine prices increased by about 5%. Being one of the key feedstocks for hexamethylene diisocyanate, volatility in chlorine price affected hexamethylene diisocyanate prices as well.

North America

Several chlor-alkali plant shutdowns in North America caused a spike in chlorine prices in the first quarter of 2022. In mid-March, an Olin chlor-alkali facility in Texas with a 3 million MTPA capacity was shut down.

In mid-February, Formosa Plastics, which has a capacity of 736 KTPA, underwent a turnaround. Traders and manufacturers were put under strain as a result of these disruptions about the availability of resources and product costs. In March, prices in the United States were estimated at 122 USD/MT ex-Louisiana. Furthermore, strong demand for downstream PVC supported chlorine offtakes in North America.

Hexamethylene Diisocyanate Price Trend for Fourth Quarter of 2021

Asia

In October, demand for the feedstock increased significantly due to increased demand for downstream Poly Vinyl Chloride (PVC) resin from the pipes and fittings industry for the replacement of ageing infrastructure.

Due to the fact that chlorine is a coproduct of caustic soda manufacturing, abundant caustic soda production coincided with a slump in PVC prices in India. In December, liquid chlorine prices in India were estimated at 125 USD/MT Ex-Works Dahej, owing to a decreased demand and supply mismatch.

Europe

Due to high energy costs and climatic issues, the availability of the feedstock in Europe remained limited. The supply of Vinnolit's Chlorine was further impacted by a force majeure at its caustic soda facility in the first part of the quarter ending December. Although supplies began to level out in late November as plant activity resumed, price remained high due to high energy prices.

North America

Because the market dynamics of PVC and Chlor-Alkali are interwoven, limiting chlorine production as a result of low operating rates in numerous caustic soda plants as a result of Hurricane Ida has strained the supply of the chemical from mid-Q2 2021.

The availability of the feedstock remained constrained as production in some caustic soda factories in the United States remained below the necessary level. However, after hitting an all-time high in October, prices began to fall in accordance with the gradual normalisation of production activity and the offseason dullness in PVC demand. Prices fell to 380 USD/MT FOB USGC in December as supply outstripped demand.

Hexamethylene Diisocyanate Price Trend for First, Second and Third Quarter of 2021

Asia

The Asian market for the feedstock displayed conflicting attitudes from multiple downstream industries, while supply varied in several segments, influencing pricing. Following the Chinese lunar holidays, certain downstream customers claimed to be short on chlorine gas, resulting in a considerable increase in its value in this segment. In India, however, significant availability due to abundant by-product caustic soda production and decreased demand pushed down the price of chlorine.

Prices in the Indian and Chinese markets fell in March, reaching 202.3 USD/MT and 211 USD/MT, respectively. During the third quarter of 2021, the Asian market saw a significant increase in the price of the feedstock. Bullish demand from the downstream PVC and agrochemicals sectors in India boosted the price of the feedstock across the nation.

Due to significant Chlor-Alkali output in the domestic market, demand and supply fundamentals remained stable. As a result of the rise in offtakes due to favourable demand, prices in India reached 108 USD/MT in September. In Q3, the ample availability of inventory levels aided in meeting the country's total demand.

Europe

During this quarter, the European market saw solid demand from the household disinfection industry. On a year-over-year basis, Europe's consumption of the feedstock increased, but production improved sufficiently to meet this demand. Due to massive plant turnarounds, imports from the United States remained suspended. Furthermore, lower output at large Middle Eastern facilities hindered the region's supply activity. Overall, regional liquid chlorine prices improved little over the previous quarter.

Several industry players saw the European domestic market as tight in Q3 2021. During Q2 and early Q3, certain scheduled and unanticipated turnarounds at various European production facilities resulted in supply bottlenecks. Following the economic recovery in key European nations such as Germany, downstream demand remained constant during the quarter, with similar volume intakes. In August, European chlorine output totaled 842 kt, a 1.2 percent decrease from July's average daily production.

North America

During this quarter, key chlorine manufacturers reported orderly pricing increases for bulk chlorine from downstream industries.

The downstream disinfectants segment's demand increased month after month. However, unusual weather hampered the production of various facilities, lowering demand for liquid chlorine from industrial chemical segments such as pulp and paper, PVC, textiles, and so on, even if demand from the pharmaceutical segment remained steady throughout the quarter.

In addition, other large factories, including Westlake, Olin, and OxyChem, declared force majeure on their chlorine operations in the Gulf of Mexico because to unfavourable weather conditions. During the March quarter, prices rose due to strong demand and insufficient supply.

In the third quarter of 2021, the price increased in the North American region. Five PVC factories along the Mississippi River in the United States were shut down ahead of Hurricane Ida's impact. Plants that produce up to 41% of North American PVC capacity gradually reopened following the incident but were hampered by a lack of crucial industrial gases.

Due to a shortage of upstream VCM feedstock, Shintech, the largest US PVC maker, shut down its 1.45 million mt/year PVC operation in Freeport, Texas, at the end of last week. During this quarter, market analysts predicted that prices would rise as a result of Ida's onslaught.

Hexamethylene Diisocyanate Price Trend For the Year 2020

Asia

Following the relaxation of COVID-19 limitations in key Asian markets, a number of chlor-alkali manufacturers announced that operations had returned to normal in the third quarter. A much-needed bounce back in the third quarter results enabled chlor-alkali producers to proceed with their scheduled forward integration initiatives in the chlorine-caustic supply chain, boosted by improved offtakes by many chlorine derivative manufacturers.

The demand for chlorine value-added products remained strong in the third quarter, driven by increased consumption from healthcare and hygiene, drinking water, and other industrial industries, according to an Indian chlor-alkali behemoth. Reduced caustic demand, on the other hand, kept output low, leading industrial grade liquid chlorine prices in Southeast Asia to stay rangebound between 200 and 260 USD/MT CFR. Hexamethylene diisocyanate prices followed a similar trend.

Europe

Demand for the feedstock increased after a significant drop in Q2 as demand from downstream PVC makers increased following a big comeback in building activity later in Q3. Despite lingering worries of a second coronavirus wave in some European states, chlor-alkali operations settled at above 80% rates as lockdowns relaxed. Chlorine's prospects remained bright, market participants were observed attempting to achieve a balance between PVC and caustic, since the latter's sales remained under pressure.

North America

During the third quarter, the North American chlorine business remained highly volatile, with supply primarily disrupted by outages induced by high winds as a result of Hurricane Laura and a succession of regional storms that followed. Despite declining demand for the by-product caustic soda lye, chlor-alkali production rates were around average in the first half of the quarter.

Constrained chlor-alkali rates and a scarcity of chlorine feedstock for PVC manufacturing exacerbated the risk of a PVC export shortage for some US firms. Later, following a dramatic increase in inquiries for chlorine derivatives such as EDC (ethylene dichloride), VCM (vinyl chloride monomer), and PVC (polyvinyl chloride), demand began to rise.

Procurement Resource provides latest prices of Hexamethylene Diisocyanate. Each price database is tied to a user-friendly graphing tool dating back to 2014, which provides a range of functionalities: configuration of price series over user defined time period; comparison of product movements across countries; customisation of price currencies and unit; extraction of price data as excel files to be used offline.

About Hexamethylene Diisocyanate

Hexamethylene diisocyanate (HDMI) is a clear liquid with no colour. Because of its exceptional characteristics, HDMI is a significant chemical building block in the manufacturing of high-value-added polyurethane.

Hexamethylene Diisocyanate Product Details

| Report Features | Details |

| Product Name | Hexamethylene Diisocyanate |

| Industrial Uses | Paints, Adhesives |

| Chemical Formula | C8H12N2O2 |

| Synonyms | 1,6-Diisocyanatohexane, 1,6-Hexamethylene diisocyanate, HMDI |

| Molecular Weight | 168.19 g/mol |

| Supplier Database | Bayer, Vencorex, BASF SE, Asahi Kasei Corporation, Tosoh, WANHUA, Merck KGaA, Chemtura/Lanxess, Mitsui Chemicals |

| Region/Countries Covered | Asia Pacific: China, India, Indonesia, Pakistan, Bangladesh, Japan, Philippines, Vietnam, Iran, Thailand, South Korea, Iraq, Saudi Arabia, Malaysia, Nepal, Taiwan, Sri Lanka, UAE, Israel, Hongkong, Singapore, Oman, Kuwait, Qatar, Australia, and New Zealand Europe: Germany, France, United Kingdom, Italy, Spain, Russia, Turkey, Netherlands, Poland, Sweden, Belgium, Austria, Ireland Switzerland, Norway, Denmark, Romania, Finland, Czech Republic, Portugal and Greece North America: United States and Canada Latin America: Brazil, Mexico, Argentina, Columbia, Chile, Ecuador, and Peru Africa: South Africa, Nigeria, Egypt, Algeria, Morocco |

| Currency | US$ (Data can also be provided in local currency) |

| Supplier Database Availability | Yes |

| Customization Scope | The report can be customized as per the requirements of the customer |

| Post-Sale Analyst Support | 360-degree analyst support after report delivery |

Note: Our supplier search experts can assist your procurement teams in compiling and validating a list of suppliers indicating they have products, services, and capabilities that meet your company's needs.

Hexamethylene Diisocyanate Production Processes

- Hexamethylene Diisocyanate Production from HMDA & Chlorine

Hexamethylenediamine (HMDA) and chlorine are used to make hexamethylene diisocyanate. Chlorine and carbon monoxide react to produce phosphogene. The acquired phosgene is reacted with HMDA, and HDI is generated as a by-product with hydrogen chloride.

Methodology

The displayed pricing data is derived through weighted average purchase price, including contract and spot transactions at the specified locations unless otherwise stated. The information provided comes from the compilation and processing of commercial data officially reported for each nation (i.e. government agencies, external trade bodies, and industry publications).

Assistance from Experts

Procurement Resource is a one-stop solution for businesses aiming at the best industry insights and market evaluation in the arena of procurement. Our team of market leaders covers all the facets of procurement strategies with its holistic industry reports, extensive production cost and pre-feasibility insights, and price trends dynamics impacting the cost trajectories of the plethora of products encompassing various industries. With the best analysis of the market trends and comprehensive consulting in light of the best strategic footstep, Procurement Resource got all that it takes.

Client's Satisfaction

Procurement Resource has made a mark for itself in terms of its rigorous assistance to its clientele. Our experienced panel of experts leave no stone unturned in ensuring the expertise at every step of our clients' strategic procurement journey. Our prompt assistance, prudential analysis, and pragmatic tactics considering the best procurement move for industries are all that sets us apart. We at Procurement Resource value our clients, which our clients vouch for.

Assured Quality

Expertise, judiciousness, and expedience are the crucial aspects of our modus operandi at Procurement Resource. Quality is non-negotiable, and we don't compromise on that. Our best-in-class solutions, elaborative consulting substantiated by exhaustive evaluation, and fool-proof reports have led us to come this far, making us the ‘numero uno' in the domain of procurement. Be it exclusive qualitative research or assiduous quantitative research methodologies, our high quality of work is what our clients swear by.

Table Of Contents

Our Clients

Get in Touch With Us

UNITED STATES

Phone:+1 307 363 1045

INDIA

Phone: +91 8850629517

UNITED KINGDOM

Phone: +44 7537 171117

Email: sales@procurementresource.com