Product

PA6 (Nylon 6) Price Trend and Forecast

PA6 (Nylon 6) Price Trend and Forecast

PA6 (Nylon 6) Regional Price Overview

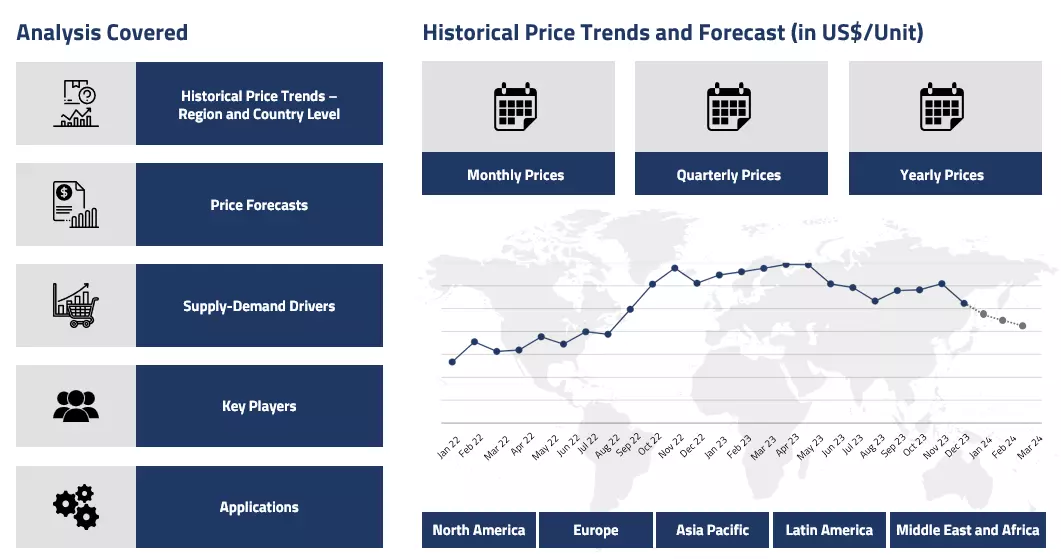

Get the latest insights on price movement and trend analysis of PA6 (Nylon 6) in different regions across the world (Asia, Europe, North America, Latin America, and the Middle East & Africa).

PA6 (Nylon 6) Price Trend for the First Half of 2025

| Product | Category | Region | Price | Time Period |

| PA6 (Nylon 6) | Chemicals | China | USD 1704/MT | January 2025 |

| PA6 (Nylon 6) | Chemicals | China | USD 1610/MT | April 2025 |

Stay updated with the latest PA6 (Nylon 6) prices, historical data, and tailored regional analysis

Asia

In Asia, particularly China, the PA6 market exhibited a fluctuating yet overall declining trend during the first half of 2025. Prices hovered around USD 1704/MT in January and fell to approximately USD 1610/MT by April. The initial decline was driven by weak Caprolactam values and subdued demand from textile and automotive sectors, which led to lower production costs and cautious purchasing behavior. A brief rebound followed, supported by restocking activities and rising feedstock prices, influenced by global crude oil movements. However, this recovery was short-lived.

PA6 (Nylon 6) Price Chart

Please Login or Subscribe to Access the PA6 (Nylon 6) Price Chart Data

Prices resumed their decline due to oversupply, falling feedstock costs, and continued weak export demand. Downstream sectors such as textiles and engineering plastics showed limited buying interest, contributing to a consistent downward movement mid-period. Although there was a slight upward revision toward the end—likely due to cost-push effects or short-term restocking—the overall trend remained negative, with the market characterized by high inventories, overcapacity, and weak downstream pull.

Europe

In Europe, the PA6 market saw a modest price increase early in the year as suppliers attempted to restore margins amid rising energy and feedstock costs. This was partially supported by a moderate rise in Caprolactam values. However, demand remained tepid, particularly from the automotive and consumer durables sectors, with many buyers relying on existing inventories, resulting in low spot trading.

As feedstock prices eased and imports from Asia intensified competition, sellers reduced prices to retain market share. Although there were announcements of Caprolactam capacity closures, immediate supply impacts were minimal. By the latter part of the period, pricing stabilized with limited buying interest, as industrial customers remained cautious amid broader economic uncertainty.

North America

In North America, the PA6 market experienced steady demand but faced rising supply pressure. Early-year support came from the resolution of logistical disruptions and restocking efforts. However, the reactivation of previously offline capacities and flat demand in sectors like construction and automotive led to oversupply. Softer feedstock prices, inflation concerns, and trade policy uncertainties further dampened market sentiment. Buyers focused on short-term procurement, avoiding long-term commitments, which led to a gradual but sustained price decline by the end of the period.

Analyst Insight

According to Procurement Resource, PA6 costs are likely to stay under a cloud in the near term based on ongoing oversupply and reluctant downstream demand. Any recovery, if at all, will rest on feedstock cost movements and continued restocking activity in core sectors.

PA6 (Nylon 6) Price Trend for the Second Half of 2024

Asia

The Asian region, particularly in countries like China, faced a decline in polyamide 6 prices during the second half of 2024. Prices started to decrease in the third quarter, largely due to weak demand from the textile and automotive sectors, combined with an oversupply situation driven by high operating rates.

By the fourth quarter, prices continued to soften as the market was further impacted by falling raw material costs, particularly pure benzene, which weakened cost support for PA6 production. Limited export orders and subdued international demand further contributed to the downward trend in prices.

Europe

In Europe, the polyamide 6 market showed a similar pattern. During the third quarter, prices remained stable, with Germany experiencing some upward movement due to localized supply and demand conditions, especially from the automotive sector. However, the fourth quarter saw a gradual decline as the European economy struggled with a contraction in the manufacturing sector. Weak demand for durable goods and a reduction in new orders led to a bearish sentiment. As the year ended, the price adjustments were mild, but the overall trend was negative, influenced by soft demand and an uncertain economic outlook in the eurozone.

North America

In North America, the pricing trend remained relatively stable in the third quarter, with some minor fluctuations driven by regional supply-demand imbalances. During the first part of H2’24, prices remained steady, but a slight decline occurred toward the end of the quarter. This decline was attributed to weakened demand, particularly from industries like textiles and automotive, which contributed to a slowdown in procurement activities. The broader economic uncertainties, including inflationary pressures and fluctuating raw material prices, further dampened market sentiment. By the fourth quarter, prices continued to trend downward, as demand remained subdued, and the market struggled to recover from earlier losses.

Analyst Insight

According to Procurement Resource, the Polyamide 6 market is likely to face continued pressures from weak downstream demand, economic uncertainties, and fluctuating raw material prices. The market may remain sluggish unless significant improvements in demand from key sectors like automotive and textiles occur, and global supply chain conditions stabilize.

PA6 (Nylon 6) Price Trend for the First Half of 2024

| Product | Category | Region | Price | Time Period |

| PA6 (Nylon 6) | Chemicals | China | 2068 USD/MT | January’24 |

| PA6 (Nylon 6) | Chemicals | China | 2078 USD/MT | June’24 |

Stay updated with the latest PA6 (Nylon 6) prices, historical data, and tailored regional analysis

Asia

Nylon 6 prices were found to be fluctuating throughout the first half of the year 2024. The first quarter was relatively firmer and more consistent than the second quarter. The average prices saw a steady incline throughout the first quarter motivated by the strengthening raw material and energy costs. With stable demands, however, the prices were more consolidated. Average prices went from about 2068 USD/MT in January’24 to around 2078 USD/MT in June’24 in the Chinese Nylon 6 market.

Moving forward, a sudden dip was seen in prices as the quarters shifted; this was primarily attributed to the decline in crude oil prices in the region. A plunge in demand trajectory also influenced the sudden dip. Suppliers got cautious and controlled the pace of supply influx to manage the pricing sentiments. This helped in some market correction in the latter phase of the second quarter. As a result, the monthly average prices for Polyacrylamide-6 reached about 2068 USD/MT in China in the month of June again. Overall, mixed market dynamics were witnessed.

Europe

The European nylon 6 markets were largely conflicted during the first two quarters of 2024. The first quarter was still slightly supportive of the market sentiments since the consistent incline in the crude oil prices anchored the upstream costs northwards. However, this cost support took a considerable hit in the latter quarter. Moreover, the manufacturing sector in key European countries like Germany was also struggling. Therefore, the downstream demands also did not support the pricing outlook desirably. Conclusively, a tugged price trajectory was witnessed for Nylon 6 in the European markets during H1’24.

North America

The pricing outlook was not very different in the American markets for PA6 during the said period. Fluctuations in the global markets also influenced the markets in the United States. The prices were found to showcase variations because of various market-driving factors. For the majority period, the demands were very stable and regular. However, the upstream factors imparted notable fluctuations. Overall, the general market outlook remained buoyant for the majority of the time period during H1’24.

Analyst Insight

According to Procurement Resource, given the recent corrections in the Chinese Nylon market, the prices are likely to plunge again in the coming months as the inventories keep stocking up.

PA6 (Nylon 6) Price Trend for the Second Half of 2023

| Product | Category | Region | Price | Time Period |

| PA6 (Nylon 6) | Chemicals | China | 1861 USD/MT | July 2023 |

| PA6 (Nylon 6) | Chemicals | China | 2030 USD/MT | December 2023 |

Stay updated with the latest PA6 (Nylon 6) prices, historical data, and tailored regional analysis

Asia

The Asian polycaprolactam market was majorly hinged upward during the second half of the year 2023. OPEC+ decided to push the crude oil prices in the third quarter to stabilize the oil market, and the edge that the Indian and Chinese markets had with access to Russian oil was no longer there; this added to the production expenses and lifted the prices even more.

The demands from the fiber and fabric industry also kept their pace. So, the Nylon 6 price trend rose during the third quarter; however, as the inventories started building up and the crude oil prices also started to normalize, the Nylon 6 prices started coming down as the fourth quarter began, but this downfall was temporary since the Asian markets picked up again as the demands rose. In the Chinese Nylon 6 market, the monthly average spot prices went from around 1861 USD/MT in July’23 to about 2030 USD/MT in December of 2023, registering an overall incline of about 9%.

Europe

Contrary to the Asian markets, the European Nylon 6 market faced depreciation in the early months of the said period. The European markets were faced with a supply glut and bearish demands. Both these factors kept holding the price trend back despite a substantial surge in crude oil prices. It was only when the inventories backtracked and the stocks became limited the suppliers were able to raise the prices in the latter half of Q4, otherwise, a very subdued market performance was witnessed.

North America

The North American market trend was also very reflective of the European market behavior during the said period. Owing to the pressurized inventories the suppliers had to keep the prices low in order to promote the product movement. As time progressed, the gap between the supply and demand outlooks started reducing steadily, and the price curve plateaued by the end of the fourth quarter. Overall, dull market sentiments were witnessed.

Analyst Insight

According to Procurement Resource, the Nylon 6 price trends are likely to continue to fluctuate going forward as well. For the coming quarter, the market projections look positive.

Nylon 6 Price Trend for the First Half of 2023

Asia

H1 2023 witnessed a mixed price pattern for Nylon 6 in the Asian market. In the Chinese domestic market, the spot prices of nylon 6 averaged around 2002 USD/MT in January and went to about 1890 USD/MT in June’23, thereby registering an overall decline of 5%. The feedstock materials caprolactam and benzene saw price hikes, leading to a momentary incline in the production costs of Nylon 6. However, the bearish downstream demand kept the overall market muted.

Europe

The European Nylon 6 market witnessed an oscillating price pattern in the first half of 2023. The prices inclined slightly given the regional imbalances; however, overall, the price trend kept on a lowered trajectory. With no fresh demands from the downstream sectors, the manufacturers were forced to lower their quotations in hopes of positive product movement. The arrival of cheap imports from China further destabilized the supply-demand dynamics of the market.

North America

The North American nylon-6 market replicated the global trend. Owing to feeble demand, the prices were kept on the lower side of the scale. However, certain peaks were observed, given the momentary rise in feedstock prices. However, any such inclines were short-lived, and overall, the pricing fundamentals kept negative.

Analyst Insight

According to the Procurement Resource, Nylon-6 prices will continue this teetering trend in the upcoming months. The demand projections do not look promising, and the fluctuating feedstock prices will continue to impact the prices.

PA6 (Nylon 6) Price Trend for the Second Half of 2022

Asia

The third quarter showcased mixed trend for the prices of Nylon 6 polymer. The price of caprolactam dipped resulting in a dip in the prices of Nylon 6 polymer. However, the demand from the textile and furniture industry helped in maintaining the price range of the commodity. In addition to that, the demand from cord-fabric, monofilament and other non-textile industries derived the price of this polymer.

The trend was however not followed by the fourth quarter. The prices fell steeply in the fourth quarter averaging around 1908 USD/MT (Spot FD China) towards the end of the said period due to weak demand and rising inventories. High tariffs and fluctuations in polymer prices further decreased the pricing of the commodity.

Europe

The price of Nylon 6 polymer dipped in the third quarter due to the fall in the price of raw materials required for its production. In addition to that, the market for nylon chips, and nylon filaments, also saw a dip in their prices. Also, the decrease in the price of caprolactam further fueled the dip in the price trend. The textile industry also did not favour the price growth of the polymer as the industrial demand remained low throughout the quarter.

The fourth quarter also followed a similar trend and the price of nylon-6 continued to dip. The contraction in demand from the apparel industry was due to a decline in the usage of the polymer in the manufacturing process. The unstable feedstock market and rising inflation further resulted in the decline in the price of this polymer.

North America

The low supply of raw materials for the production of Nylon-6 polymer resulted in the decline in the prices of this polymer in the North American market. However, the industries tend to maintain the equilibrium by increasing the demand for this fibre throughout the third quarter.

The textile industry remains the major driver of the market for the third quarter. However, due to the strong supply and uncertain market conditions, the prices continued to fall. In the fourth quarter also, the prices followed a similar trend. High inventory and the low cost of raw materials were the major cause of the decline in the prices of the commodity.

Analyst Insight

The prices of nylon- 6 are likely to remain volatile during the coming month given the uncertainty of the market both in terms of raw materials and polymer along with the strong supply from the manufacturers.

PA6 (Nylon 6) Price Trend For the Second Quarter of 2022

Asia

Owing to the rising crude oil prices, the prices of feedstock benzene skyrocketed globally, thereby driving the prices of caprolactam (CPL) further. In the Chinese domestic market, the cost of caprolactam averaged 14800 RMB/MT during the said quarter. Since feedstock caprolactam remained firm throughout the domestic market, it supported the higher prices of PA6.

However, towards the end of June, the prices of PA6 began to dip due to the great production and off-season muted demand from the downstream industries. PA6 prices averaged 16,500 RMB/MT in the domestic market.

Europe

The extreme instability and volatility impacted the prices of petrochemicals, thereby affecting all nylon-based products. The high costs of benzene and caprolactam caused the PA6 prices to inflate in the European market. Per ton price of benzene averaged 1427 USD FOB Hamburg in the said quarter.

Since the production of PA6 is a highly energy-intensive process, the manufacturers passed the rising costs of inputs to the downstream sectors. The strong demand from the fibre, automotive and semiconductor sectors sustained the high price trend of PA6.

North America

In line with the European market, the prices of PA6 in the US domestic arena remained strong throughout the quarter. The tightened supply, low inventories and increasing demand from the downstream sector sustained the higher prices across the US market.

PA6 (Nylon 6) Price Trend For the First Quarter of 2022

PA 6 prices were around 15933.33 RMB/MT in China in March 2022. In February, BASF announced that it will increase the price of carpolactum and PA 6 by 0.10 USD/lb, effective March 1.

In 2020, Asia-Pacific had the highest share of the polyamide-6 market, accounting for 40.6%. Due to the rapidly growing population, rise in the automotive industry, favourable government policies, growing electrical and electronics industries, and growing textile production in developing economies such as China, Japan, South Korea, and India in this region, Asia-Pacific is dominating the market.

Because of the rising usage of polyamide-6 in automobiles, the automotive industry has the largest market share of all end-users in the worldwide polyamide-6 market. Growing vehicle production and sales, manufacturing sector advancements, low-cost labour availability, and raw material availability, notably in India and China, are likely to raise polyamide-6 demand in the region.

Procurement Resource provides latest prices of PA6 (Nylon 6). Each price database is tied to a user-friendly graphing tool dating back to 2014, which provides a range of functionalities: configuration of price series over user defined time period; comparison of product movements across countries; customisation of price currencies and unit; extraction of price data as excel files to be used offline.

About PA6 (Nylon 6)

PA6 (Nylon 6) is a polymer that was developed to reproduce the properties of nylon 6,6 without violating its production patent. PA6 (Nylon 6), a semicrystalline polyamide, is not a condensation polymer unlike most other nylons. It is widely used in plastic and textile industry. It is produced using ring-opening polymerization. Owing to its unique properties like high tensile strength, excellent resistance to abrasion and high elasticity and lustre, demand for Nylon 6 has been growing in packaging and engineering plastics sector.

PA6 (Nylon 6) Product Details

| Report Features | Details |

| Product Name | PA6 (Nylon 6) |

| Industrial Uses | Carpets, Tire cords, Apparel, Hosiery and upholstery, Seat belts, Parachutes, Ropes and industrial cords, Extrusion, injection and blow moulding, Engineering materials, Moulded parts |

| Chemical Formula | (C6H11NO)n |

| Synonyms | 25038-54-4, Polyamide 6 (PA6), Poly(azepan-2-one); poly(hexano-6-lactam), Poly[azanediyl(1-oxohexane-1,6-diyl)], Polycaprolactam |

| Supplier Database | BASF SE, Koninklijke DSM N.V., Ter Hell Plastic GmbH, Formosa Group , Radici Partecipazioni SpA , Rabigh Refining and Petrochemical Co SJSC or Petro Rabigh, Lanxess AG, Evonik Industries AG |

| Region/Countries Covered | Asia Pacific: China, India, Indonesia, Pakistan, Bangladesh, Japan, Philippines, Vietnam, Iran, Thailand, South Korea, Iraq, Saudi Arabia, Malaysia, Nepal, Taiwan, Sri Lanka, UAE, Israel, Hongkong, Singapore, Oman, Kuwait, Qatar, Australia, and New Zealand Europe: Germany, France, United Kingdom, Italy, Spain, Russia, Turkey, Netherlands, Poland, Sweden, Belgium, Austria, Ireland Switzerland, Norway, Denmark, Romania, Finland, Czech Republic, Portugal and Greece North America: United States and Canada Latin America: Brazil, Mexico, Argentina, Columbia, Chile, Ecuador, and Peru Africa: South Africa, Nigeria, Egypt, Algeria, Morocco |

| Currency | US$ (Data can also be provided in local currency) |

| Supplier Database Availability | Yes |

| Customization Scope | The report can be customized as per the requirements of the customer |

| Post-Sale Analyst Support | 360-degree analyst support after report delivery |

Note: Our supplier search experts can assist your procurement teams in compiling and validating a list of suppliers indicating they have products, services, and capabilities that meet your company's needs.

PA6 (Nylon 6) Production Processes

- Production of PA6 (Nylon 6) via Ring-Opening Polymerisation; and via Two Step Polymerisation

In order to produce PA6 (Nylon 6), the ring opening polymerisation process is utilised. In this process, caprolactam is used as a monomer, which undergoes hydrolytic mechanism to finally give PA6 (Nylon 6).

Methodology

The displayed pricing data is derived through weighted average purchase price, including contract and spot transactions at the specified locations unless otherwise stated. The information provided comes from the compilation and processing of commercial data officially reported for each nation (i.e. government agencies, external trade bodies, and industry publications).

Assistance from Experts

Procurement Resource is a one-stop solution for businesses aiming at the best industry insights and market evaluation in the arena of procurement. Our team of market leaders covers all the facets of procurement strategies with its holistic industry reports, extensive production cost and pre-feasibility insights, and price trends dynamics impacting the cost trajectories of the plethora of products encompassing various industries. With the best analysis of the market trends and comprehensive consulting in light of the best strategic footstep, Procurement Resource got all that it takes.

Client's Satisfaction

Procurement Resource has made a mark for itself in terms of its rigorous assistance to its clientele. Our experienced panel of experts leave no stone unturned in ensuring the expertise at every step of our clients' strategic procurement journey. Our prompt assistance, prudential analysis, and pragmatic tactics considering the best procurement move for industries are all that sets us apart. We at Procurement Resource value our clients, which our clients vouch for.

Assured Quality

Expertise, judiciousness, and expedience are the crucial aspects of our modus operandi at Procurement Resource. Quality is non-negotiable, and we don't compromise on that. Our best-in-class solutions, elaborative consulting substantiated by exhaustive evaluation, and fool-proof reports have led us to come this far, making us the ‘numero uno' in the domain of procurement. Be it exclusive qualitative research or assiduous quantitative research methodologies, our high quality of work is what our clients swear by.

Table Of Contents

Our Clients

Get in Touch With Us

UNITED STATES

Phone:+1 307 363 1045

INDIA

Phone: +91 8850629517

UNITED KINGDOM

Phone: +44 7537 171117

Email: sales@procurementresource.com