Product

Rebar Price Trend and Forecast

Rebar Price Trend and Forecast

Rebar Regional Price Overview

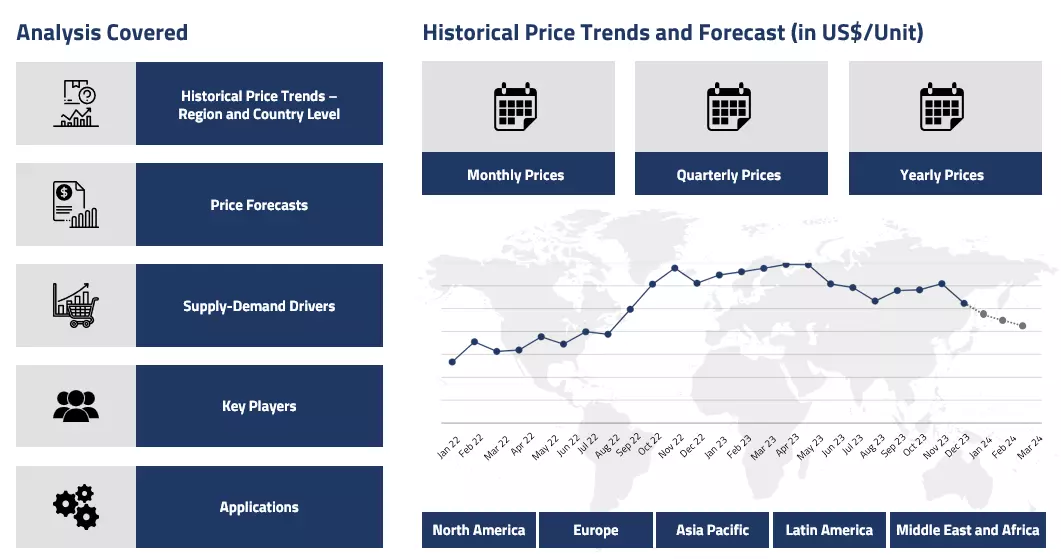

Get the latest insights on price movement and trend analysis of Rebar in different regions across the world (Asia, Europe, North America, Latin America, and the Middle East & Africa).

Rebar Price Trend for the First Half of 2025

In the first half of 2025, global rebar prices showed a generally downward trend, shaped by weak construction demand, seasonal slowdowns, and regional economic factors. Most markets, especially in Europe, the Middle East, and Asia, faced sluggish demand despite steady or rising supply levels. Ramadan and seasonal restocking played a role in dampening buying activity in the Middle East, where even strong infrastructure spending couldn’t fully support prices. Regional producers adjusted prices to keep up with lower order volumes.

Rebar Price Chart

Please Login or Subscribe to Access the Rebar Price Chart Data

In Europe, rebar prices declined across countries like Poland and Italy due to weak construction activity and limited support from import restrictions. The UK and US markets also saw soft demand, with buyers delaying projects and maintaining a cautious approach. Although Germany held prices firm for a while, even its market began to show signs of pressure as foreign offers became more attractive and scrap trends suggested potential weakening.

In Asia, oversupply from China remained a key challenge. Domestic demand in China stayed low due to poor weather, construction delays, and uncertain stimulus measures. Export volumes increased sharply, adding pressure to regional markets such as Southeast Asia and the Middle East. Turkey faced similar issues, with reduced exports and weak domestic demand driving prices lower. Raw materials like iron ore, scrap, and coking coal also dipped, reflecting reduced production appetite and margin pressures among mills.

Analyst Insight

According to Procurement Resource, Rebar prices may face continued pressure unless there’s a meaningful recovery in construction demand or stimulus from major economies, particularly China.

Rebar Price Trend for the Second Half of 2024

The prices of rebar exhibited mixed trends during the second half of 2024. In the Chinese market, the third quarter began on a weaker note as demand from various downstream sectors remained subdued. This sustained the downward trend from the previous quarter, leading to a steady decline in the prices of its primary feedstock, steel.

Prices reached their lowest point in early September, after which they briefly stabilized before beginning to rise toward the end of the quarter. This upward movement was largely driven by expectations of Federal Reserve rate cuts, which weakened the dollar and made the commodity more attractive in international markets.

However, as optimism surrounding the rate cuts faded, prices began to decline again in late October. The lack of strong demand support contributed to this downturn. Overall, global rebar prices followed a similar fluctuating pattern, influenced by the trajectory of steel prices.

Analyst Insight

According to Procurement Resource, the prices of rebar are expected to showcase similar movements going forward if the demand from the downstream construction sector remains subdued.

Rebar Price Trend for the First Half of 2024

In the first half of 2024, rebar prices experienced fluctuations driven by a combination of weak demand, sufficient supply, and varying regional market dynamics. Globally, the rebar market saw a general downward trend, with prices declining in several key regions, largely due to the subdued construction activity that failed to support a stronger market for long products. In Turkey, rebar prices saw a slight decrease initially, but towards the end of May, prices stabilized, even seeing a minor uptick as local producers tested market responses to new price floors.

The Turkish rebar market was characterized by stagnant demand, with most sales directed towards a few countries, while major European buyers remained largely inactive. This lack of demand kept Turkish mills operating at low capacity, with production expected to decline further due to upcoming maintenance and the holiday season.

In Europe, rebar prices fluctuated differently across regions. Northern Europe experienced a slight decline in prices due to fierce competition among manufacturers, with some large companies reducing prices to maintain order volumes despite the weak construction activity. In Italy, however, rebar prices managed to increase slightly in May, driven by a temporary rise in consumer activity and production cuts by local steelmakers to balance supply and demand. Despite this, the overall demand from the construction sector remained insufficient to sustain a prolonged price increase, leading to expectations of price stabilization or a potential decline in the near term.

In North America, rebar prices also declined during the first half of the year due to weakening demand and sufficient supply. The slowdown in construction activity and delayed funding for infrastructure projects added pressure on rebar prices. The North American market, similar to other regions, faced challenges from low scrap prices, which further influenced the downward trend.

Meanwhile, in China, rebar prices showed some resilience in May, supported by government incentives for the real estate market and interest rate cuts by the Chinese Central Bank. However, the market faced negative price dynamics towards the end of the period due to changes in national standards, leading to a drop in prices as traders unloaded existing stocks. Overall, rebar prices in China were expected to remain low, with high inventories and low demand continuing to influence market conditions. Across all regions, the first half of 2024 was marked by a cautious and challenging environment for rebar prices, with market participants closely monitoring supply-demand balances and external economic factors.

Analyst Insight

According to Procurement Resource, the price of Rebar is expected to remain more or less stagnant in the forthcoming quarters as well as the momentum set by the previous months is likely to be moderately supported by global demand and evolving economic policies.

Rebar Price Trend for the Second Half of 2023

In the third and fourth quarters of 2023, global rebar prices experienced fluctuations across various markets, particularly in Turkey, China, and the US. In Turkey, prices surged due to increased production costs and limited export opportunities from North African countries. However, demand began to go southwards towards the end of November, although the market received a boost from renewed purchases by Israel and Yemen, this was still insufficient in keeping the market trend of rebar upwards.

In the US, prices remained stable through most of H2 of 2023 but declined in the last month amid reduced construction activity and stagnant procurement rates of other downstream industries. Meanwhile, in China, rebar prices stabilized amid limited demand, with producers cautious about raising prices to avoid losing sales volume.

The manufacturers anticipated subdued demand to persist through the winter months, with some traders postponing purchases until after the Spring Festival. Additionally, Ukraine's exports saw a significant decline in revenues and volumes from July to December '23, projecting a negative influence on the rebar price trend.

Analyst Insight

According to Procurement Resource, the price of Rebar is estimated to struggle with continuous fluctuations in trading activities and demand dynamics from the downstream industries.

Rebar Price Trend for the First Half of 2023

Rebar prices experienced mixed market trend during the said period of H1’23. The consumer demands from the construction sector, along with the feedstock steel costs, drove the Rebar market sentiments. In Asia, especially the Chinese market, the construction industry struggled severely because of the stretched lockdowns put in place to contain Covid 19 pandemic. And when the lockdowns were abolished, the Rebar demands didn’t pick up immediately.

So, with a slow improvement in the construction business, a rise in Rebar market trend was observed in Q1’23 as the prices rose by around 2% within the first three months. However, with improved global supply chains, a slump in prices was observed in the second quarter since Q2 closed at an average spot price of about 514 USD/MT in June’23. Overall, mixed market sentiments were observed.

Analyst Insight

According to Procurement Resource, after tribulations in the Rebar market trend, the prices are anticipated to seek stability in the coming months.

Procurement Resource provides latest prices of Rebar. Each price database is tied to a user-friendly graphing tool dating back to 2014, which provides a range of functionalities: configuration of price series over user defined time period; comparison of product movements across countries; customisation of price currencies and unit; extraction of price data as excel files to be used offline.

About Rebar

Rebar (or reinforcing bar), refers to massed reinforcing of steel or steel reinforcement, that is, steel bars installed inside the plain cement concrete. Rebar, being a mesh of steel wires or steel bar , is mostly utilised as a tension device in reinforced concrete to build structures. The product is widely utilised in the construction sector as it strengthens and aids the concrete under tension. Further, it can significantly boost the tensile strength of the structure.

Rebar Product Details

| Report Features | Details |

| Product Name | Rebar |

| Synonyms | ArcelorMittal S.A, EVRAZ plc, Gerdau SA , Nucor Corporation, Tata Steel Limited |

| Industrial Uses | Reinforced masonry, Reinforced concrete, Others |

| Region/Countries Covered | Asia Pacific: China, India, Indonesia, Pakistan, Bangladesh, Japan, Philippines, Vietnam, Iran, Thailand, South Korea, Iraq, Saudi Arabia, Malaysia, Nepal, Taiwan, Sri Lanka, UAE, Israel, Hongkong, Singapore, Oman, Kuwait, Qatar, Australia, and New Zealand Europe: Germany, France, United Kingdom, Italy, Spain, Russia, Turkey, Netherlands, Poland, Sweden, Belgium, Austria, Ireland Switzerland, Norway, Denmark, Romania, Finland, Czech Republic, Portugal and Greece North America: United States and Canada Latin America: Brazil, Mexico, Argentina, Columbia, Chile, Ecuador, and Peru Africa: South Africa, Nigeria, Egypt, Algeria, Morocco |

| Currency | US$ (Data can also be provided in local currency) |

| Supplier Database Availability | Yes |

| Customization Scope | The report can be customized as per the requirements of the customer |

| Post-Sale Analyst Support | 360-degree analyst support after report delivery |

Note: Our supplier search experts can assist your procurement teams in compiling and validating a list of suppliers indicating they have products, services, and capabilities that meet your company's needs.

Rebar Production Process

- Production of Rebar via Hot-Rolling Process

The steps involved in the production of Rebar generally include conversion of steel (scrap/molten) into molten steel and then into semi-finished products through continuous casting, which is followed by direct rolling/hot rolling process and thermo mechanical treatment. Thus, melting scrap steel in an electric arc furnace and subsequently moulding it into billets that are further hot-rolled produces Rebar.

Methodology

The displayed pricing data is derived through weighted average purchase price, including contract and spot transactions at the specified locations unless otherwise stated. The information provided comes from the compilation and processing of commercial data officially reported for each nation (i.e. government agencies, external trade bodies, and industry publications).

Assistance from Experts

Procurement Resource is a one-stop solution for businesses aiming at the best industry insights and market evaluation in the arena of procurement. Our team of market leaders covers all the facets of procurement strategies with its holistic industry reports, extensive production cost and pre-feasibility insights, and price trends dynamics impacting the cost trajectories of the plethora of products encompassing various industries. With the best analysis of the market trends and comprehensive consulting in light of the best strategic footstep, Procurement Resource got all that it takes.

Client's Satisfaction

Procurement Resource has made a mark for itself in terms of its rigorous assistance to its clientele. Our experienced panel of experts leave no stone unturned in ensuring the expertise at every step of our clients' strategic procurement journey. Our prompt assistance, prudential analysis, and pragmatic tactics considering the best procurement move for industries are all that sets us apart. We at Procurement Resource value our clients, which our clients vouch for.

Assured Quality

Expertise, judiciousness, and expedience are the crucial aspects of our modus operandi at Procurement Resource. Quality is non-negotiable, and we don't compromise on that. Our best-in-class solutions, elaborative consulting substantiated by exhaustive evaluation, and fool-proof reports have led us to come this far, making us the ‘numero uno' in the domain of procurement. Be it exclusive qualitative research or assiduous quantitative research methodologies, our high quality of work is what our clients swear by.

Table Of Contents

Our Clients

Get in Touch With Us

UNITED STATES

Phone:+1 307 363 1045

INDIA

Phone: +91 8850629517

UNITED KINGDOM

Phone: +44 7537 171117

Email: sales@procurementresource.com