Product

Acrylonitrile Butadiene Styrene (ABS) Price Trend and Forecast

Acrylonitrile Butadiene Styrene (ABS) Price Trend and Forecast

ABS Regional Price Overview

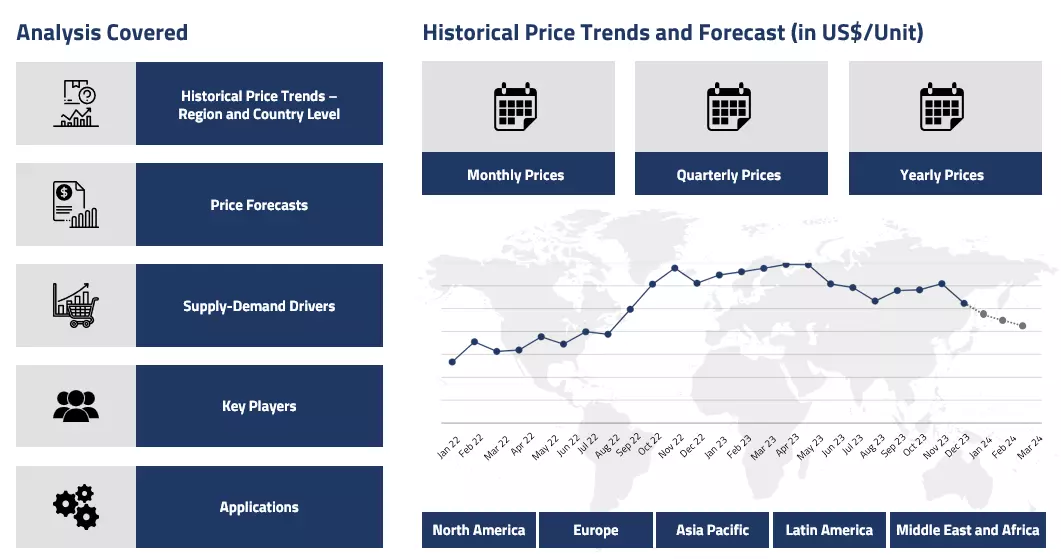

Get the latest insights on price movement and trend analysis of Acrylonitrile Butadiene Styrene (ABS) in different regions across the world (Asia, Europe, North America, Latin America and Middle East & Africa).

Acrylonitrile Butadiene Styrene (ABS) Price Trend for the Q4 of 2024

| Product | Category | Region | Price | Time Period |

| Acrylonitrile Butadiene Styrene (ABS) | Chemicals | Asia | 1,471 USD/MT | October'24 |

| Acrylonitrile Butadiene Styrene (ABS) | Chemicals | Asia | 1,426 USD/MT | December'24 |

Stay updated with the latest Acrylonitrile Butadiene Styrene (ABS) prices, historical data, and tailored regional analysis

Asia

A supply-demand imbalance in the ABS market in Asia during the fourth quarter of 2024 led to a downward trend in prices. In the early part of the quarter, production faced brief delays due to scheduled maintenance, but inventory levels remained stable, preventing any major supply shortages. Demand from home appliances and other downstream industries was lower than expected, and high inventory levels further pressured the market. While macroeconomic factors initially created some optimism, demand did not pick up.

Acrylonitrile Butadiene Styrene (ABS) Price Chart

Please Login or Subscribe to Access the Acrylonitrile Butadiene Styrene (ABS) Price Chart Data

The market remained stagnant, with both buyers and producers hesitating to make significant moves. Despite a slight increase in production toward the end of the quarter, demand did not improve enough to drive prices upward. As a result, the market continued to experience weak activity. Prices stood at approximately 1,471 USD/MT (CFR) in October and declined to around 1,426 USD/MT in December.

Europe

In Europe, the ABS market faced a challenging quarter due to rising energy expenses and stricter environmental regulations that impacted production. The increase in operating costs, combined with weak demand from key sectors such as automotive and consumer goods, created a difficult market environment. Although supply rebounded toward the end of the quarter, it was not sufficient to counterbalance the higher operational expenses. As a result, prices remained elevated despite low demand. European producers struggled to reduce prices due to ongoing supply chain disruptions that continued to affect availability. Downstream buyers found little relief, as market conditions remained relatively tight.

North America

North America's ABS market displayed mixed signals in Q4 of 2024. At the start of the quarter, production saw a slight improvement, although facilities continued to experience intermittent disruptions. Despite this, demand remained weak, particularly in key sectors such as automobiles and construction, leading to minimal buying activity. Some plants shut down, and by the end of the quarter, supply constraints emerged, with rising feedstock prices—especially for benzene and styrene—adding cost pressures. However, the increase in production costs did not translate into a significant rise in prices due to subdued demand. The North American market experienced a slow recovery, with prices showing little sign of a reversal. While the quarter ended with lingering uncertainties, the market continued to adjust to fluctuating production and demand trends.

Analyst Insight

According to Procurement Resource, the ABS market is expected to remain under pressure, with weak demand from key sectors and fluctuating production costs limiting any significant price recovery. However, gradual stabilization in supply and potential improvements in downstream industries may provide slight relief.

Acrylonitrile Butadiene Styrene Price Trend for the Q3 of 2024

Asia

In the Asian market, the acrylonitrile butadiene styrene prices demonstrated a mixed trajectory, initially showing a slight upward trend at the beginning of July. This increase was supported by a temporary boost in production and profitability in previous months, despite an overall operating load. However, the early July market was characterized by weak demand, particularly from home appliance manufacturers, who were impacted by seasonal holiday shutdowns and reduced factory operations. This trend continued into late July, with a lack of substantial improvement in demand, leading to subdued trading activity.

By mid-quarter, acrylonitrile butadiene styrene prices faced downward pressure, reflecting the weak demand and increased inventories. However, towards the end, the trend turned bullish, offering little hope to the market participants. Overall, the Asian market for acrylonitrile butadiene styrene was characterized by relative stability amidst a backdrop of cautious optimism, driven by speculative movements regarding future supply contraction.

Europe

In Europe, the acrylonitrile butadiene styrene market witnessed a slightly different dynamic as compared to the Asian countries. Although there was some correlation with trends observed in Asia and North America, the European market showed resilience amid ongoing supply chain adjustments. The prices of the commodity showcased a smooth inclining trend. However, challenges from upstream raw materials continued to impact the acrylonitrile butadiene styrene pricing patterns a little. Despite this, the butadiene market in Europe was stable, providing some necessary cost support. European manufacturers appeared more optimistic about demand recovery, particularly in sectors like construction and consumer goods.

North America

In North America, the acrylonitrile butadiene styrene market mirrored some of the challenges faced in Asia. The prices showed slight stagnancy due to low demand from key sectors such as automotive and home appliances. The weak terminal demand was further heightened by holidays affecting downstream production levels. Additionally, as crude oil prices decreased, feedstock prices for styrene stabilized, providing limited support for acrylonitrile butadiene styrene costs.

Analyst Insight

According to Procurement Resource, the price trend of Acrylonitrile Butadiene Styrene is expected to return stronger in the months ahead as the market players estimate the revival of the market based on seasonal demand.

Acrylonitrile Butadiene Styrene Price Trend for the Q2 of 2024

| Product | Category | Region | Price | Time Period |

| Acrylonitrile Butadiene Styrene (ABS) | Chemicals | Europe | 1490 USD/MT to 1534 USD/MT | Q2 2024 |

Stay updated with the latest Acrylonitrile Butadiene Styrene (ABS) prices, historical data, and tailored regional analysis

Asia

In the initial phase of the second quarter, the pricing patterns of acrylonitrile butadiene styrene were stagnant in China, but as May approached, the functioning of the market improved. During this month, the manufacturing industries reported an increase in their profit margins along with the excessive pressure on the operating sector.

The manufacturers, however, gradually increased their production volumes in accordance with the demand for the commodity. However, the costs of production were adversely affected by declining prices of feedstock commodities. Additionally, as the quarter progressed towards its end, the demand from the downstream industries eased out, weakening the market momentum, resulting in oscillations in acrylonitrile butadiene styrene price trend throughout Q2 of 2024.

Europe

The European market demonstrated resilience during the second quarter of 2024, supported by the sustained demand and production delays caused by adverse weather conditions. In the first two months of the quarter, the European ABS price quotations rose from an average of 1490 USD/MT to 1534 USD/MT. However, even after the appreciation of market momentum, the profit margins of manufacturers remained constricted.

They, on the other hand, received a stable number of both domestic and overseas inquiries. However, as the quarter progressed, the feedstock industries extended only limited support, restricting the growth potential of the acrylonitrile butadiene styrene market. The downstream activities were also challenged by the heavy rains and excessive flooding in many regions of Germany. This further intensified the already existing logistical challenges due to the diversion of the Red Sea route and rising geopolitical tensions.

North America

In the second quarter of 2024, acrylonitrile butadiene styrene prices in the North American market remained stable despite moderate demand and balanced inventory levels. However, rising geopolitical tensions globally and reduced industrial production since May have impacted the functioning of supply chains. The downstream automotive sector saw slight increases in sales, though ongoing procurement cuts posed challenges.

The export prices were stagnant due to tighter global supply outweighing increased domestic production. Also, major producers like Ineos Styrolution and Sabic faced production issues due to local water supply reductions, leading to force majeure declarations and shutdowns. Overall, market participants are cautious, with some delaying purchases in hopes of price drops, while the tight supply and steady automotive demand suggest an upward price trend.

Analyst Insight

According to Procurement Resource, the price trend of Acrylonitrile Butadiene Styrene is estimated to move in the northward direction with the help of expanding demand from the downstream industries and escalating freight charges.

Acrylonitrile Butadiene Styrene (ABS) Price Trend for the Q1 of 2024

| Product | Category | Region | Price | Time Period |

| Acrylonitrile Butadiene Styrene (ABS) | Chemicals | China | 10662 RMB/MT | January 2024 |

| Acrylonitrile Butadiene Styrene (ABS) | Chemicals | China | 12162 RMB/MT | March 2024 |

| Acrylonitrile Butadiene Styrene (ABS) | Chemicals | Europe | 1587 USD/MT | March 2024 |

Stay updated with the latest Acrylonitrile Butadiene Styrene (ABS) prices, historical data, and tailored regional analysis

Asia

Acrylonitrile Butadiene Styrene price trend continued its weak run of the past quarter for some time in January’24 as well. The first few days of the new year saw a loose market run as the inventory stocks were still able to support the downstream demands; however, soon, a supply crunch began in the region.

A sharp and consistent jump in crude oil prices in the international markets primarily propelled the commodity prices in the Asian markets. ABS prices that averaged around 10662 RMB/MT in the Chinese Acrylonitrile Butadiene Styrene market in the second week of January reached up to about 12162 RMB/MT in the latter days of March’24. This yielded a sharp rise of more than 10% in the Chinese ABS market prices within the said three months of the first quarter of 2024. Overall, a rising price trajectory was witnessed throughout the given time period.

Europe

The European Acrylonitrile Butadiene Styrene market followed its Asian counterpart during the given time period. The prices were witnessed to be inclining for the majority of the said duration even though the market had a slow start. Earlier, the consumption from the downstream industries was still underwhelming. Thus, the prices remained low as the existing stocks were worrying the suppliers.

However, as Ukraine started bombing the Russian energy facilities and the energy prices started rising rapidly, the whole region went under inflation. The downstream demands from the plastic industries also started rising swiftly. This directly resulted in a growth of Acrylonitrile Butadiene Styrene prices in the second half of the first quarter in the European markets as well.

North America

The ABS price situation in the US market was not much different from the Asian and European markets as the prices fluctuated in a similar manner here as well. A weak consumer demand at the beginning of the quarter kept the price graph restrained initially. As the quarter progressed, not much change was seen in the demand trajectory. However, a sharp rise in the feedstock costs pushed up the upstream costs, which added to the suppliers’ pressure. As a result, a steady incline was witnessed in the ABS price graph in the second half of the first quarter. Overall, mixed market sentiments were witnessed.

Analyst Insight

According to Procurement Resource, the ABS prices are likely to rise further in the coming months since crude oil prices are also expected to grow. Upstream cost pressure is stressing the Acrylonitrile Butadiene Styrene market.

Acrylonitrile Butadiene Styrene Price Trend for the October - December of 2023

Asia

In the fourth quarter, the Acrylonitrile Butadiene Styrene industry faced challenges as the cost of operation was reduced drastically. On the other hand, the product's supply was abundant, leading to a significant increase in inventory while demand from downstream industries failed to perform its role. Additionally, the upstream Acrylonitrile Butadiene Styrene materials exhibited mixed performance, with acrylonitrile prices slightly increasing due to high propylene costs. The domestic butadiene market saw a slight weakening, while styrene prices declined due to weakened crude oil and market demand.

Europe

During the months of October and November, the prices of Acrylonitrile Butadiene Styrene appreciated by almost 5% as the demand for synthetic rubber in the European countries took a positive turn. However, this relief for the traders was only short-lived.

The prices of exports dropped, and the manufacturers, during the end phase of the quarter, were forced to reduce their production outputs to keep the profit margins stable. This move also helped in controlling the rising level of inventories as the demand in the later months failed to suffice with production. A major cause of this downturn was the mixed signals given by the economic recovery rates of the region.

North America

The fourth quarter witnessed some stability in the Acrylonitrile Butadiene Styrene market. The prices seemed to be guided by the rise in the automotive and polymer industries' dynamics and some subtle and slow recovery in the economic sector of the region.

Analyst Insight

According to Procurement Resource, the price trend of Acrylonitrile Butadiene Styrene are estimated to be driven by the global revival of the automotive industries. However, the trade sanctions from Europe may prove to be a hindrance to the market.

Acrylonitrile Butadiene Styrene (ABS) Price Trend for the July - September of 2023

Asia

Acrylonitrile Butadiene Styrene or ABS is a polymer of three distinct monomeric units, namely Acrylonitrile, Butadiene, and Styrene. Acrylonitrile Butadiene Styrene is a unique blend of all their qualities and thus is extensively used for various purposes like plasticizers, food handling, equipment making, aircraft and other structure manufacturing, etc.

This wide array of utilization makes ABS a safer commodity for suppliers to stock because of low-risk involvement. This led to a rapid accumulation of Acrylonitrile Butadiene Styrene stocks in the Chinese market even before the third quarter began and widened the supply and demand gap. So, because of this disparity in supply and demand dynamics, the Acrylonitrile Butadiene Styrene prices remained on a downward journey in the Asian regional market during the said period of Q3’23.

Europe

Even around the highly uncertain economic situations in the European region, the outlook for the Acrylonitrile Butadiene Styrene market was somewhat stable. Suppliers were cautious with ordering bulk quantities, and the demands were dull. Overall, an almost plateaued price graph was observed for ABS.

North America

The North American Acrylonitrile Butadiene Styrene market almost mirrored the price trend for the Asian Acrylonitrile Butadiene Styrene market. With the parity between supply quantities and sluggish demands, the market trend were relatively stable for ABS during the said period.

Analyst Insight

According to Procurement Resource, the market dynamics are likely to improve for Acrylonitrile Butadiene Styrene (ABS) going forward since the consumption is set to rise with gradually improving the manufacturing sector.

Acrylonitrile Butadiene Styrene (ABS) Price Trend for the First Half of 2023

Asia

Acrylonitrile Butadiene Styrene (ABS) prices fluctuated on the lower end in the Asian market. Prices had a stable start in the Chinese domestic market, with spot prices averaging around 11750 RMB/MT in January, and by the end of the second quarter, prices had reached an average of about 10400 RMB/MT. Dull downstream demands contributed to these dimming trend.

Feedstock acrylonitrile, butadiene, and styrene supplies supported the upstream costs. As the Chinese industries started reviving, chemical plants started reopening, and feedstock prices were depleted further, but market demands too rose, and a muted but stable supply-demand dynamic was maintained.

Europe

European ABS prices exhibited mixed price trend in the first half of 2023. Quarter 1 started with about 1951 USD/MT (EXW Germany, ABS Pellets) and ended at around 1905 USD/MT in March’23. The same downward movement continued in the second quarter as the falling feedstock costs and stalling demands kept the market sentiments muted. Amid the acute energy crisis and contracting purchasing power, the construction businesses have taken a serious hit in Europe, impacting the overall prices of Acrylonitrile Butadiene Styrene (ABS) negatively.

North America

Like the European market, the American market also witnessed fluctuating price patterns. The first quarter witnessed a price decline because of oversupplied inventories and dull demands. Downstream construction and housing sectors struggled because of the rise in inflation and interest rates. Amid high-cost pressure, suppliers had to reduce their profit margins to compete in the international market. Prices plateaued at the beginning of the second quarter but declined as the quarter ended.

Analyst Insight

According to Procurement Resource, the Acrylonitrile Butadiene Styrene (ABS) prices are expected to continue their oscillating run in the coming quarter. Given the current inventories, a healthy demand dynamic will positively influence ABS prices in the global market.

Acrylonitrile Butadiene Styrene (ABS) Price Trend for the Second Half of 2022

Asia

The price trend for Acrylonitrile Butadiene Styrene (ABS) registered fluctuating patterns in the said quarter. Owing to the low upstream cost pressure of feedstocks butadiene and styrene, the prices of ABS suffered in the market. However, market sentiments turned viable towards the end of the quarter. With the removal of the covid restrictions, the Chinese powerhouses started churning out products at a much faster rate than the market demand, hence the ABS prices stood firm and did not record a drastic jump in prices.

Europe

The ABS prices in the European market remained on the lower side of the scale throughout the third quarter. The decreased market enquiries from the construction and automotive sectors owing to the phenomenon of demand destruction considering higher operating costs and the energy crisis dragged the prices down.

North America

The crude oil and natural gas prices fell after reaching peaks owing to the Russia-Ukraine conflict, which impacted the petrochemical industry. The lowered butadiene and styrene prices influenced the ABS price trend. The lowered demand from the market due to strong speculations of recession led to stockpiling of the product in the market further driving the prices down.

Analyst Insight

According to Procurement Resource, the price of ABS is expected to stay firm with periodic fluctuations as the market is still recovering from the turmoil of a year ago. Though the prices will remain on the lower end due to adequate supply and weak demand.

Acrylonitrile Butadiene Styrene (ABS) For the Second Quarter of 2022

Asia

ABS price increase is attributed to the supply shortages of primary raw materials like styrene, acrylonitrile, and butadiene.

The price of styrene averaged CFR 1221 USD/MT and CFR 1640 USD/MT (South-East Asia) for acrylonitrile. Raw materials shortages, along with the rising freight and transportation costs, disrupted the suppliers’ operations and pushed the prices to rise further.

Europe

Europe is already experiencing supply chain shocks for many industries because of the ongoing Russia-Ukraine confrontation. Hence, due to the rising crude oil prices and freight charges, the industries are facing an energy crisis, and the prices are increasing at a fast pace. The price of acrylonitrile averaged CFI 1788 USD/MT.

Acrylonitrile Butadiene Styrene (ABS) For the First Quarter of 2022

Asia

In March 2022, in China, the price of styrene, a key feedstock, was 9350 RMB/MT. The expansion of the ABS market was driven favourably by the increasing penetration of ABS applications in the building industry. One of the biggest elements impacting industrial growth is rising building expenditure, particularly in emerging nations, as disposable income rises.

Pipes, plastic sheets, and fittings are all made of ABS. Product development was accelerated by technological improvements and product developments, such as nylon and ABS alloys with increased strength. Furthermore, the product's design flexibility, chemical resistance, and exceptional mechanical qualities aided its use in a variety of end-use sectors.

Acrylonitrile Butadiene Styrene (ABS) For the Fourth Quarter of 2021

Asia

Upstream styrene, acrylonitrile, and butadiene performance in China was disappointing in the last quarter, owing to demand stagnation in both the domestic and international markets. As a result of falling demand and declining feedstocks, prices fell in the last quarter of the year. After the end of December 2021, ex-Shanghai Per ton price of acrylonitrile butadiene styrene was estimated to be 2432 USD/MT.

The Indian market was underwhelming as well. While the festive season boosted demand, the introduction of the new covid variant followed by a regular demand dip caused prices to fall in Q4. Imports of feedstocks were also sluggish, therefore prices for ABS low flow grade on CFR basis fell from 190,180 INR/MT in October to 155,400 INR/MT in December.

Europe

Due to strong demand from downstream sectors, the European ABS market stayed strong throughout the quarter. The price pattern validated the above sentiment as in early October, ABS prices were evaluated at 2850 USD/MT FOB, while in the last week of December, they were assessed at 3015 USD/MT.

Throughout the quarter, strong feedstock styrene price pushed up overall production costs and, as a result, ABS pricing. Demand was strong throughout the quarter, with few to no variations due to the winter vacation season. Imports from Asia remained restricted due to high freight costs, making imported goods unsustainable and uncompetitive.

Despite a reduction in upstream styrene monomer costs, ABS contract prices increased to 1195 EUR/MT FD Northwest Europe in January 2022. Butadiene and acrylonitrile price increases, on the other hand, spurred the producers to pursue higher contract price targets.

North America

Feedstock costs changed throughout the period, causing downstream ABS prices to fluctuate as well. The rehabilitation from the catastrophe due to Hurricane Ida extended until mid-Q4, putting a strain on styrene supply. While prices rose in October 2021, they fell in November and then rose again in December, reaching 2948 USD/MT on a free delivery basis. In Q4, demand was consistent, but slowed as the year progressed, owing to the winter holiday season.

Acrylonitrile Butadiene Styrene (ABS) For the First, Second, and Third Quarters of 2021

Asia

In the first quarter of 2021, the Asian market saw a significant increase in overall the demand from a variety of downstream industries. Several small-scale ABS machines in China were offline for a few days over the Lunar New Year holiday in February, halting domestic supply. Meanwhile, demand from local electronics and home appliance manufacturers increased dramatically in India, supporting its prices. Supply remained limited during the quarter, causing the ABS prices in India to rise from 2016 USD/MT in January 2021 to 2120.3 USD/MT in March 2021.

The market showed conflicting attitudes in the second quarter, with some countries' demand improving successfully while others battled with the pandemic's ramifications or a slow economic recovery. In China, demand was solid to stable, with the construction and automobile sectors showing signs of recovery as they returned to pre-pandemic levels.

In the second half of the quarter, however, vigorous restocking and lower upstream resources kept the prices stable. Meanwhile, in the Indian market, low demand and abundant supply of ABS, as well as the raw material styrene monomer, pushed prices lower in the early days, before gradually climbing in the month of June. As a result, throughout the month, ABS prices hovered at 2734 USD/MT in India and 2080 USD/MT in China.

The market had a proliferative trajectory in pricing in Q3 2021, as supply of acrylonitrile and styrene remained restricted due to China's power constraint. Following the 'duo cutbacks' on energy usage and carbon emissions in September, most Chinese businesses were forced to reduce their production activity, putting a strain on the polymer’s market.

Due to the significant scarcity of feedstocks caused by plant turnarounds in China and South Korea, the regional ABS market remained tense. In August, Shandong Hai Jiang abruptly shut down its acrylonitrile factory owing to a technical issue, while Liaoning Petrochemicals and Ningbo LG chem reported maintenance outages in the third quarter.

FOB Qingdao-China prices in September were 2817 USD/MT, up 74 USD/MT from July 2021. Because of a shortage of raw materials from South Korea and China, the Indian market remained sluggish in Q3.

Europe

ABS had substantial demand support from both domestic and international sources in the European market. Lower upstream supplies in Europe halted its production across the continent, despite robust demand throughout the quarter. Furthermore, a container shortage along the Europe-Asia route, combined with strong export demand from Asia, forced prices to rise, causing manufacturers to operate at lower capacities. Meanwhile, a leading ABS manufacturer in Europe increased its ABS prices (resin) by approximately 476.9 USD/MT, effective March 1, 2021.

In the second quarter, the revival of the European economy was the primary factor that boosted the demand in the region. Many contracts were received, according to manufacturers, with some of them booked until the end of the year.

The market confidence resulting from successful vaccination efforts and the relaxation of lockdown restrictions in most European countries was ascribed to the high demand for ABS. As a result of strong demand and improving production activity, prices in Europe skyrocketed during this quarter.

During Q3, the market in Europe showed conflicting sentiments for ABS prices. The price trend was pushed higher by a significant increase in the value of the feedstocks acrylonitrile and styrene, as well as reduced production rates in the region. The declaration of force majeure by AnQor in the Netherlands, one of the world's leading producers of acrylonitrile, pushed up the prices even further in August.

Furthermore, the exponential growth in the prices in the European market was caused by increasing interoceanic freight expenses throughout Asia-Europe and US-Europe trading lines. After the lifting of force majeure and the resumption of operations at various plants, the prices remained stable at the conclusion of the quarter.

North America

Several plant activities were impacted by winter storms in the United States in the first quarter of 2021. Several upstream materials, such as acrylonitrile and styrene, were in short supply. ABS supply in the region was still insufficient to meet regional demand. The supply chain remained interrupted as a result of dented production lines, with little hope for recovery.

In the second quarter, the market saw a sharp surge in pricing, owing to limited supply activity in the region. Following the winter shutdown in February, the prices skyrocketed in April and May, before beginning to decline as major manufacturers resumed plant operations in the country.

Following the country's successful vaccination push, the market saw a significant increase in demand from the downstream construction and automotive industries. As a result, by the end of May, there had been a significant increase in ABS prices, which then decreased in June, eventually settling at 2910 USD/MT in the United States.

ABS prices increased exponentially in the third quarter of 2021. The growing pricing trend was caused by high demand from downstream sectors and unavailability of feedstock. Hurricane Ida wreaked havoc on oil and gas refineries, as well as other manufacturing plants, in August, disrupting the supply chain and driving up the price of ABS.

Due to a power loss caused by Hurricane Ida in Louisiana, Cornerstone had to shut down its acrylonitrile factory while INEOS Styrolutions' styrene plant in Texas was shut down for repairs at the end of September. In September, FD-US Gulf monthly average prices were 2958 USD/MT, up 132 USD/MT from July.

Latin America

In March 2021, Brazilian styrene and polystyrene maker Innova declared force majeure at its Triunfo styrene monomer factory. The plant was forced to shut down due to a power outage. When Innova's operations were restarted, the catalyst was found to be severely damaged. This action hindered ABS supplies in Brazilian markets where styrene is a key ingredient.

Acrylonitrile Butadiene Styrene (ABS) For the Year 2020

Asia

Although the automotive sector is a primary driver of the Acrylonitrile Butadiene Styrene market in Asia, the market received substantial support from makers of appliances, toys, and air conditioners despite a significant decline in automobile sales in the third quarter. Chinese ABS makers reported excellent profits which did not dip below 85% in Q3. However, in Q4, China's import ABS market had four consecutive weeks of decline due to reduced demand during the year-end slump and declining styrene prices.

Southeast Asian markets, meanwhile, jumped on the bandwagon, albeit at a slower rate. The weekly aggregate of ABS prices on a CIF China basis fell by more than 150 USD/MT, or more than 6%, since the decline began in early December. Meanwhile, ABS prices on a CIF SEA basis decreased by less than 85 USD/MT in recent weeks. Reduced feedstock prices were highlighted as one of the primary reasons for the market's decline.

Europe

In Q3, European ABS makers announced a new wave of price hikes, claiming that demand for the material far outstripped regional supply. Non-automotive industries such as electrical appliances, furniture, and toys, among others, showed signs of improvement ahead of automotive, propelling Q3 results for most ABS producers.

Following the economic disruptions caused by the COVID-19 pandemic, European appliance demand increased in September, owing to increased spending on home modifications by end-consumers.

North America

The demand grew in Q3 2020, and prices began to firm up in the second week of August. Increased purchases of domestic equipment and air conditioners during the epidemic, as many people were quarantined at home and adopted a work-from-home culture, boosted market sentiments.

After suffering a huge setback as a result of the economic slowdown, demand in the US automotive sector began to pick up near the end of the year, indicating a V-shaped rebound in sectoral growth. The price in the United States increased in August due to restricting worldwide availability. Because engineered plastic is commonly utilised in the production of toys, players anticipated an increase in demand in the run-up to the Christmas holidays.

Latin America

In 2020, Brazil's demand for the polymer was estimated to be 120k MT and it continued to increase as demand for automobiles, electronic and electrical equipment, and consumer items rose.

Procurement Resource provides latest prices of Acrylonitrile Butadiene Styrene (ABS). Each price database is tied to a user-friendly graphing tool dating back to 2014, which provides a range of functionalities: configuration of price series over user defined time period; comparison of product movements across countries; customisation of price currencies and unit; extraction of price data as excel files to be used offline.

About ABS

ABS, an amorphous polymer and opaque thermoplastic, is a polymer comprised of three distinct monomers in various proportions: acrylonitrile, butadiene, and styrene. Due to its toughness, resistance to heat, and anti-corrosive properties, it is utilised in a wide variety of applications. It is the most often used plastic and the material of choice for 3-D printing. Additionally, it is easily recyclable.

ABS Product Details

| Report Features | Details |

| Product Name | Acrylonitrile Butadiene Styrene (ABS) |

| Chemical Formula | (C8H8·C4H6·C3H3N)n |

| Industrial Uses | Plasticizers, Medical Technology, Alternative Energy, Food Handling and Equipment, Aircraft, Defense and Aerospace |

| HS Code | 390330 |

| Supplier Database | Asahi Kasei, Sabic, Styron, Kumho Petrochemical Company, Formosa Plastic Company, Styrolution |

| Molecular Weight | 211.30 g/mol |

| Synonyms | Acrylonitrile butadiene styrene, 2-Propenenitrile, Polymer with 1,3-butadiene, Ethenylbenzene acrylonitrile-butadiene-styrene |

| Region/Countries Covered | Asia Pacific: China, India, Indonesia, Pakistan, Bangladesh, Japan, Philippines, Vietnam, Iran, Thailand, South Korea, Iraq, Saudi Arabia, Malaysia, Nepal, Taiwan, Sri Lanka, UAE, Israel, Hongkong, Singapore, Oman, Kuwait, Qatar, Australia, and New Zealand Europe: Germany, France, United Kingdom, Italy, Spain, Russia, Turkey, Netherlands, Poland, Sweden, Belgium, Austria, Ireland Switzerland, Norway, Denmark, Romania, Finland, Czech Republic, Portugal and Greece North America: United States and Canada Latin America: Brazil, Mexico, Argentina, Columbia, Chile, Ecuador, and Peru Africa: South Africa, Nigeria, Egypt, Algeria, Morocco |

| Currency | US$ (Data can also be provided in local currency) |

| Supplier Database Availability | Yes |

| Customization Scope | The report can be customized as per the requirements of the customer |

| Post-Sale Analyst Support | 360-degree analyst support after report delivery |

Note: Our supplier search experts can assist your procurement teams in compiling and validating a list of suppliers indicating they have products, services, and capabilities that meet your company's needs.

ABS Production Processes

- Production of ABS from the Emulsion Process

The production of ABS takes place from the emulsion process. In the emulsion process, ABS is obtained by the polymerization of acrylonitrile, butadiene, and styrene.

Methodology

The displayed pricing data is derived through weighted average purchase price, including contract and spot transactions at the specified locations unless otherwise stated. The information provided comes from the compilation and processing of commercial data officially reported for each nation (i.e. government agencies, external trade bodies, and industry publications).

Assistance from Experts

Procurement Resource is a one-stop solution for businesses aiming at the best industry insights and market evaluation in the arena of procurement. Our team of market leaders covers all the facets of procurement strategies with its holistic industry reports, extensive production cost and pre-feasibility insights, and price trends dynamics impacting the cost trajectories of the plethora of products encompassing various industries. With the best analysis of the market trends and comprehensive consulting in light of the best strategic footstep, Procurement Resource got all that it takes.

Client's Satisfaction

Procurement Resource has made a mark for itself in terms of its rigorous assistance to its clientele. Our experienced panel of experts leave no stone unturned in ensuring the expertise at every step of our clients' strategic procurement journey. Our prompt assistance, prudential analysis, and pragmatic tactics considering the best procurement move for industries are all that sets us apart. We at Procurement Resource value our clients, which our clients vouch for.

Assured Quality

Expertise, judiciousness, and expedience are the crucial aspects of our modus operandi at Procurement Resource. Quality is non-negotiable, and we don't compromise on that. Our best-in-class solutions, elaborative consulting substantiated by exhaustive evaluation, and fool-proof reports have led us to come this far, making us the ‘numero uno' in the domain of procurement. Be it exclusive qualitative research or assiduous quantitative research methodologies, our high quality of work is what our clients swear by.

Related News

Table Of Contents

Our Clients

Get in Touch With Us

UNITED STATES

Phone:+1 307 363 1045

INDIA

Phone: +91 8850629517

UNITED KINGDOM

Phone: +44 7537 171117

Email: sales@procurementresource.com