Product

Allyl PEG Price Trend and Forecast

Allyl PEG Price Trend and Forecast

Allyl PEG Regional Price Overview

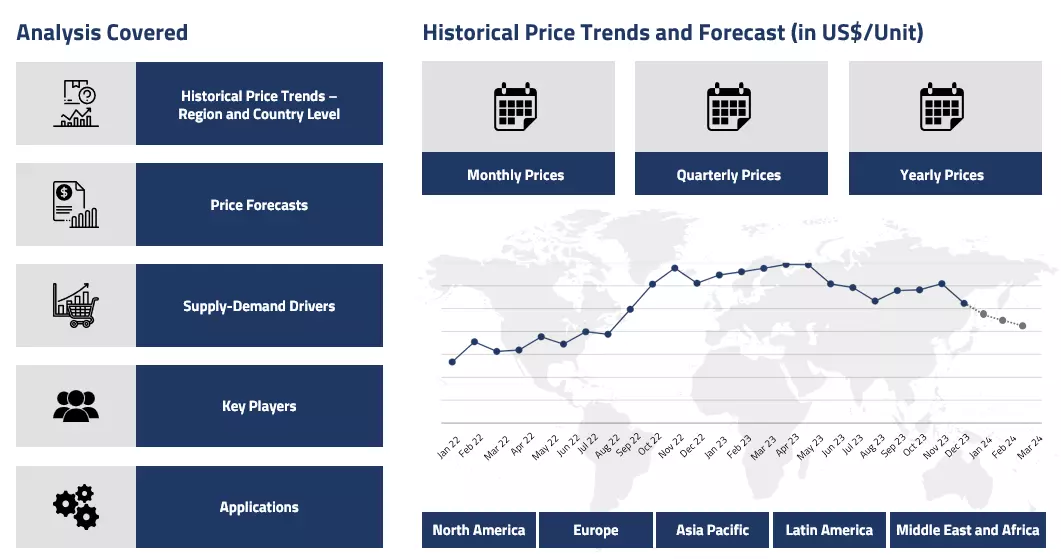

Get the latest insights on price movement and trend analysis of Allyl PEG in different regions across the world (Asia, Europe, North America, Latin America, and the Middle East & Africa).

Allyl PEG (Polyethylene Glycol) Price Trend for the Year 2023

Allyl PEG uses allyl chloride and polyethylene glycol for its manufacturing, and thus, their market behaviors closely replicate each other. The year 2023 was a turbulent one for the allyl PEG market prices. For the majority time span, swift and short ranged fluctuations were witnessed in the price curve. The year started on a positive note as the prices started to firm in the first quarter, particularly in the Asian markets. However, as the months progressed, the prices started sliding down, primarily because of low upstream cost support.

Allyl PEG (Polyethylene Glycol) Price Chart

Please Login or Subscribe to Access the Allyl PEG (Polyethylene Glycol) Price Chart Data

A persistent downfall in crude oil prices resulted in the noted depreciation in production costs. This continued until the end of the third quarter. Further, the year-ending quarter witnessed an even steeper fall in the allyl PEG price graph. Owing to the supply chain restrictions and the erupted conflict in the Middle East, the global trade dynamics were disturbed. Market demands for Allyl PEG declined substantially, and the prices fell further down. Overall, mixed market sentiments were witnessed.

Analyst Insight

According to Procurement Resource, the Allyl PEG price trend is likely to stabilize in the coming months. Demands will take some time to rebound, given the current economic outlook and other economic factors.

Procurement Resource provides latest prices of Allyl PEG. Each price database is tied to a user-friendly graphing tool dating back to 2014, which provides a range of functionalities: configuration of price series over user defined time period; comparison of product movements across countries; customisation of price currencies and unit; extraction of price data as excel files to be used offline.

About Allyl PEG

Allyl PEG, also known as APEG, is created through the reaction of ethylene oxide or EO and allyl alcohol. It is a reactive poly-ether that is used to make polycarboxylate-based water reducing agents. Liquid-based allyl PEG can be stored in iron-based drums, whereas flakes can be packed in woven bags made or composed of polypropylene.

Allyl PEG Product Details

| Report Features | Details |

| Product Name | Allyl PEG |

| Industrial Uses | Manufacture of PCA type water reducing agent, Production of synthetic polymers |

| Chemical Formula | C3H5(C2H4O)nOH |

| Synonyms | Allyl polyethylene glycol, Polyoxyethylene allyl, Allyl ether |

| Supplier Database | Lotte Chemical, Clariant, Shanghai Bronkow Chemical, Jiangsu Haishihua, Liaoning Kelong, Fengchen Group |

| Region/Countries Covered | Asia Pacific: China, India, Indonesia, Pakistan, Bangladesh, Japan, Philippines, Vietnam, Iran, Thailand, South Korea, Iraq, Saudi Arabia, Malaysia, Nepal, Taiwan, Sri Lanka, UAE, Israel, Hongkong, Singapore, Oman, Kuwait, Qatar, Australia, and New Zealand Europe: Germany, France, United Kingdom, Italy, Spain, Russia, Turkey, Netherlands, Poland, Sweden, Belgium, Austria, Ireland Switzerland, Norway, Denmark, Romania, Finland, Czech Republic, Portugal and Greece North America: United States and Canada Latin America: Brazil, Mexico, Argentina, Columbia, Chile, Ecuador, and Peru Africa: South Africa, Nigeria, Egypt, Algeria, Morocco |

| Currency | US$ (Data can also be provided in local currency) |

| Supplier Database Availability | Yes |

| Customization Scope | The report can be customized as per the requirements of the customer |

| Post-Sale Analyst Support | 360-degree analyst support after report delivery |

Note: Our supplier search experts can assist your procurement teams in compiling and validating a list of suppliers indicating they have products, services, and capabilities that meet your company's needs.

Allyl PEG Production Processes

- Production of Allyl PEG using Polymer Capping

The polymer capping process is used to produce allyl PEG from polyethylene glycol ether and allyl chloride. Polyethylene glycol (methyl-terminated) reacts with allyl chloride to produce allyloxy-methyl terminated polyethylene glycol ether, also known as allyl PEG.

Methodology

The displayed pricing data is derived through weighted average purchase price, including contract and spot transactions at the specified locations unless otherwise stated. The information provided comes from the compilation and processing of commercial data officially reported for each nation (i.e. government agencies, external trade bodies, and industry publications).

Assistance from Experts

Procurement Resource is a one-stop solution for businesses aiming at the best industry insights and market evaluation in the arena of procurement. Our team of market leaders covers all the facets of procurement strategies with its holistic industry reports, extensive production cost and pre-feasibility insights, and price trends dynamics impacting the cost trajectories of the plethora of products encompassing various industries. With the best analysis of the market trends and comprehensive consulting in light of the best strategic footstep, Procurement Resource got all that it takes.

Client's Satisfaction

Procurement Resource has made a mark for itself in terms of its rigorous assistance to its clientele. Our experienced panel of experts leave no stone unturned in ensuring the expertise at every step of our clients' strategic procurement journey. Our prompt assistance, prudential analysis, and pragmatic tactics considering the best procurement move for industries are all that sets us apart. We at Procurement Resource value our clients, which our clients vouch for.

Assured Quality

Expertise, judiciousness, and expedience are the crucial aspects of our modus operandi at Procurement Resource. Quality is non-negotiable, and we don't compromise on that. Our best-in-class solutions, elaborative consulting substantiated by exhaustive evaluation, and fool-proof reports have led us to come this far, making us the ‘numero uno' in the domain of procurement. Be it exclusive qualitative research or assiduous quantitative research methodologies, our high quality of work is what our clients swear by.

Table Of Contents

Our Clients

Get in Touch With Us

UNITED STATES

Phone:+1 307 363 1045

INDIA

Phone: +91 8850629517

UNITED KINGDOM

Phone: +44 7537 171117

Email: sales@procurementresource.com