Product

Butyl Acrylate Price Trend and Forecast

Butyl Acrylate Price Trend and Forecast

Butyl Acrylate Regional Price Overview

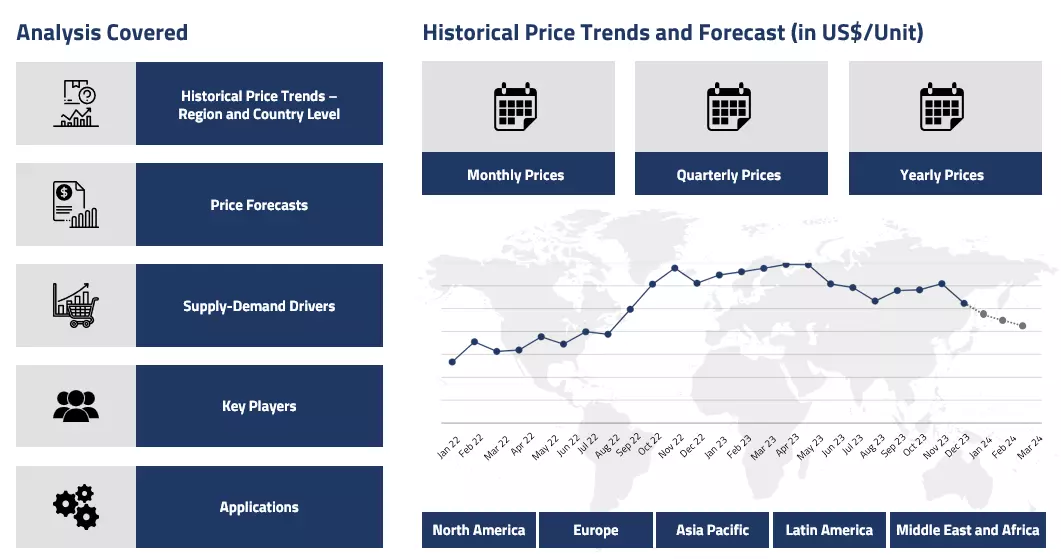

Get the latest insights on price movement and trend analysis of Butyl Acrylate in different regions across the world (Asia, Europe, North America, Latin America, and the Middle East & Africa).

Butyl Acrylate Price Trend for the Q4 of 2024

Asia

The Butyl Acrylate market in Asia exhibited a fluctuating trend throughout the fourth quarter of 2024. Early quarter saw price gains driven by the rising costs of key feedstocks, particularly n-butanol in the Chinese market. Supply tightness emerged when several regional producers underwent planned turnarounds, further supporting the upward momentum.

Butyl Acrylate Price Chart

Please Login or Subscribe to Access the Butyl Acrylate Price Chart Data

However, by mid-quarter, increased supply availability following maintenance completions and capacity restarts led to downward pressure on prices. The market was characterized by cautious buying behavior, particularly in December, as downstream industries maintained a wait-and-see approach amid economic uncertainties.

Europe

European Butyl Acrylate prices followed a relatively stable to soft trajectory during Q4'24. The market was influenced by sluggish demand from key end-use sectors, particularly the construction and automotive industries. While producers attempted to maintain margins amid fluctuating raw material costs, competitive pressure from Asian imports constrained their pricing power. The quarter was marked by sufficient inventory levels and moderate trading activity, with most buyers adhering to need-based purchasing strategies. Energy costs continued to impact production economics, though their influence was less pronounced compared to previous quarters.

North America

The North American Butyl Acrylate market demonstrated mixed sentiments throughout Q4'24. The quarter began on a firm note, supported by steady demand from the coatings and adhesives sectors. However, as the quarter progressed, prices began to soften due to improved product availability and moderate buying interest. The market dynamics were influenced by upstream acrylic acid trends and varying demand patterns across different end-use segments. Producer margins remained under pressure, particularly when feedstock costs showed volatility, though balanced supply-demand fundamentals helped maintain market stability.

Analyst Insight

According to Procurement Resource, the Butyl Acrylate market is expected to remain sensitive to feedstock price movements and downstream demand patterns in the coming months.

Butyl Acrylate Price Trend for the Q3 of 2024

Asia

In Asia, the butyl acrylate market displayed more stability, particularly in Japan, where the balance between supply and demand remained relatively steady. The Japanese market saw stability due to consistent industrial activity and reliable demand from downstream sectors, including construction and coatings. Despite the rainy season disrupting construction projects temporarily, manufacturers in Japan were able to maintain price stability by adjusting their production rates and aligning with market conditions.

The production costs for butyl acrylate remained fluctuating, with the price of one of its key feedstocks, n-butanol, declining slightly during the quarter, which helped keep butyl acrylate prices stable. Market participants adapted to these shifts, ensuring adequate supply while managing operational challenges such as weather disruptions. Although Japan's construction sector was impacted by these weather-related factors, business confidence remained stable, and new orders for future projects indicated some potential for growth, even if the short-term demand for butyl acrylate remained subdued.

Europe

In Europe, the butyl acrylate market faced a bearish trend, largely driven by stagnating demand from the downstream construction and coatings sectors. The region's construction industry, which is a key consumer of butyl acrylate, continued to struggle with reduced activity. Ongoing inflationary pressures added to the economic challenges, leading to a decline in purchasing volumes and demand from end-users. Manufacturing activities in Europe also remained sluggish, resulting in surplus inventories of butyl acrylate.

In Germany, for instance, prices declined consistently throughout the quarter as demand from the coatings and construction sectors underperformed. This downward pressure on prices was exacerbated by weak seasonal performance, leading to reduced inquiries from buyers and limiting the ability of market players to maintain previous price levels. Although there were some signs of potential improvement in housing and construction activity across parts of Europe, overall market sentiment remained bearish, with inflation and high production costs continuing to weigh on the sector.

North America

In North America, the butyl acrylate market experienced a stable yet bearish trend during Q3 2024. Prices in the region were primarily driven by lower production costs due to declines in the prices of key feedstocks, such as n-butanol and acrylic acid. The reduction in feedstock prices helped sustain stable pricing levels for butyl acrylate, even though demand from downstream sectors, particularly coatings and construction, remained weak. In the United States, the construction sector saw mixed signals during the quarter. Additionally, the impact of adverse weather condition also slowed construction activities in earlier in the quarter, further contributed to the subdued demand. Despite a stable pricing trend, the bearish outlook in North America persisted due to these sectoral challenges, as well as an oversupply of butyl acrylate in the market.

Analyst Insight

According to Procurement Resource, the price trend of Butyl Acrylate is expected to maintain its momentum in the quarters ahead as well as the key market parameters looks promising.

Butyl Acrylate Price Trend for the Q2 of 2024

Asia

In the second quarter of 2024, the butyl acrylate market in China exhibited a stable price trend, influenced by steady raw material costs for n-butanol. Throughout the quarter, despite some downstream industries reducing their prices, the market price for butyl acrylate remained consistent due to balanced cost support and stable supply. The shift of Chinese economic indicators in the green zone also extended broader support to the butyl acrylate prices.

Among the end-user industries, procurement rates in polymer and plastic industries were tepid, leading to a gradual fall in the profit margins of both manufacturers and domestic traders. In view of this, the inventory levels increased steadily; however, there is an expectation of a slight recovery in demand after a period of suppression towards the end of the quarter, stabilizing the overall dynamics. The overseas trading sector also sustained its pricing quotations of butyl acrylate as the number of overseas inquiries increased even after the significant rise in transportation charges.

Europe

The European butyl acrylate market maintained stability despite an upward trend in inflationary pressure and limited industrial growth rates. Although the European Union's inflation rate saw a slight increase, this did not significantly impact the butyl acrylate market. Additionally, the production cost of butyl acrylate in Europe decreased due to lower prices of its feedstocks, n-butanol and acrylic acid.

The inventory levels in Europe were sufficient to meet the demand from downstream construction and coating industries, ensuring a balanced supply-demand dynamic. Therefore, the pricing dynamics between n-butanol, acrylic acid, and butyl acrylate remained consistent throughout the second quarter of 2024, indicating continued market stability for this commodity.

North America

In the US, the butyl acrylate market saw a downward trend after the initial period of stability during Q2'24. This decline was primarily due to reduced market activity and sufficient inventory levels that met the demand from the downstream construction and coating sectors.

Despite a decrease in carry-over inventories, confidence within the US construction industry remained high. The construction industry noted a slight dip in infrastructure projects following the Federal Reserve's decision to maintain high interest rates, which hampered the growth of the butyl acrylate market. The fluctuating production costs of butyl acrylate were influenced by varying trends in feedstock prices, with n-butanol prices rising and acrylic acid prices declining, contributing to overall production cost instability.

Analyst Insight

According to Procurement Resource, the price trend of Butyl Acrylate is expected to be driven by the expansion of the consumer base and escalation in the cost of production.

Butyl Acrylate Price Trend for the Q1 of 2024

| Product | Category | Region | Price | Time Period |

| Butyl Acrylate | Chemicals | USA | USD 1700/MT | March 2024 |

Stay updated with the latest Butyl Acrylate prices, historical data, and tailored regional analysis

Asia

During the first three months of the year 2024, the price of butyl acrylate experienced a slight decrease in China. Despite this, the overall market stabilized after the holiday period, with steady utilization rates in production capacity. However, while factories remained bullish in their outlook and pushed up their production rates, downstream buyers adopted a cautious approach, contributing to the stagnancy in the overall dynamics of the market.

However, a significant improvement in the trading activities gave the market its required momentum but was still insufficient in driving the trajectory of butyl acrylate prices in a northward direction. The production boost in the acrylic acid and ester industry post-holiday is expected to further support the butyl acrylate market, strengthening the supply of raw materials in the region and reducing the dependency on overseas imports.

Europe

The downward trend in butanol prices reversed in the first quarter of 2024 as the downstream sectors showed signs of modest demand, helped by certain major players in the industry lifting chemical quotations.

The prices of butyl acrylate in Europe thus moved towards stability due to unexpected rises in the cost of feedstock and crude oil. Additionally, the Red Sea route disruption resulted in lower import volumes, which put stress on supply networks and depleted inventories. Despite trading challenges and rising sanctions on Russian imports, butyl acrylate prices in the region were able to sustain in the green zone of the pricing spectra.

North America

In the North American market, butyl acrylate prices attained a stable stance in the first quarter of 2024 as sufficient inventory levels meet the moderate demand from the paint and coating sector. There was a sudden rise in the cost of production due to the increase in price quotations of base chemicals by the industry giants, but in view of frail procurement rates, particularly from the overseas industries, the traders hesitated in increasing their price quotations.

On a similar note, there was also an increase in crude oil prices during the period, leading to higher energy costs for butyl acrylate production; the pricing trajectory of butyl acrylate remained stagnant throughout the quarter. This cautious approach reflects concerns about the potential oversupply of butyl acrylate despite the stable market conditions in the forthcoming quarters.

Analyst Insight

According to Procurement Resource, the price trend of Butyl Acrylate is expected to face the consequences of a gradual rise in inventory levels and meek demand dynamics of the downstream industries in the next few quarters.

Butyl Acrylate Price Trend for the October - December of 2023

Asia

In the early phase of the fourth quarter, butanol and acrylic acid, which serve as the feedstock of butyl acrylate in Asia, experienced a decline due to insufficient demand support, negatively affecting the butyl acrylate price trend. Along with this, the excess number of shipments and reduced inquiries from end-users and upstream industries also added to the list of concerns of traders. However, in the end, months, the trading activities surged, leading to an upward trend in the cost of raw materials, but other factors, such as demand and dynamics of end-user industries, restricted the momentum of the butyl acrylate prices.

Europe

In Europe, the fourth quarter saw a stable movement in butyl acrylate prices due to supply-demand imbalances caused by sanctions on Russian chemicals, which limited the raw material supply in the region. Despite these challenges, stable demand from downstream industrial and construction sectors contributed to the upward momentum in butyl acrylate prices. Additionally, the performance of the market was also driven by higher upstream propylene prices and increased trading activities. However, depleting inventories and rising costs of production also had a major influence on this surge.

North America

In North America during the fourth quarter, an increase in raw material costs along with a hike in demand and limited supply resulted in upward movement of the butyl acrylate market. However, the butyl acrylate market faced challenges towards the end of the quarter due to a substantial decline in crude oil costs. In addition to this, port congestion in the Panama Canal disrupted the supply-demand balance, leading to a fall in export rates.

Analyst Insight

According to Procurement Resource, the price trend of Butyl Acrylate are likely to be based on the movement of butanol and acrylic acid prices along with improvement in the paints and coatings sectors.

Butyl Acrylate Price Trend for July - September of 2023

Asia

Butyl acrylate price trend witnessed a positive momentum in the third quarter of 2023. The trend was influenced by the inclining number of new orders from the downstream paint and coatings sectors while the supply chains struggled to perform effectively. This inefficiency led to the depletion of the inventory levels while the consumption rates of consumers rose, disturbing the supply-demand equilibria. In addition to this, the butyl acrylate price graph also moved northwards with the surge in the cost of feedstock materials.

Europe

The butyl acrylate price analysis of the third quarter showed that the trend was exactly the opposite of what was observed in the Asia-Pacific region. The cost of feedstock materials was stagnant during this phase, and the performance of the downstream industries remained weak. In addition to this, the sluggish nature of procurement from the downstream industries caused the stockpiles of butyl acrylate to rise in the region, hurting the butyl acrylate regional prices and movement of its price trend.

North America

In North America, the butyl acrylate price trend declined during the initial months of the third quarter on account of the underperformance of the downstream industries. The condition of the feedstock and upstream market also remained feeble during this phase. However, as the quarter progressed, the demand for butyl acrylate surged positively affecting its price trend, positively influencing its price trend. This inclination in the demand pressurized the inventory and supply chains, and thus, this further supported the rise in the butyl acrylate price trend.

Analyst Insight

According to Procurement Resource, the price trend of Butyl Acrylate are expected to follow an oscillating trajectory as the demand from the downstream paints and coatings sector seems uncertain.

Butyl Acrylate Price Trend for the First Half of 2023

Asia

The price trend for Butyl acrylate in the Asia-Pacific region registered an oscillating pattern in the first two quarters of 2023. Initially, the prices turned positive and rose, given the rise in downstream demand. However, the demand was short-lived, and the prices fell. The fall in the market's productivity due to the holiday season in the Chinese domestic market affected the pricing fundamentals. The prices suffered from the rising uncertainties in the fertilizer market along with the declining demand for sulphuric acid in the regional market.

In addition, the feedstock market also suffered from low sales, and a constant struggle between supply and demand in the region led to a rise in inventory levels. This same lowered trend continued in the fourth quarter. Overall, the butyl acrylate prices kept towards the lower end in Q4 with series to inclines and declines given the market uncertainties. The prices of butyl acrylate averaged around 8485 RMB/MT in the Chinese domestic market in June '23.

Europe

The prices of butyl acrylate plummeted in Europe in view of weak demand and rising inventories. The acrylic acid demand from Asian importers decreased, and the shipments of feedstock increased, which led to an increase in the level of stockpiles in the region. The prices also suffered from the rising competition and see-saw trend followed by the supply-demand equilibria that forced the retailers to sell their products at reduced rates.

North America

The price trend for butyl acrylate in North America were similar to that observed in the European and Asia-Pacific regions. The rising inflation rates in the region supported the declining trajectory of prices. The banking sector increased the interest rates to keep up with the inflation speed, which had a negative impact on the prices of butyl acrylate. As a result, the region's economic activities slowed down, aiding the significant decline in demand, especially from the adhesives and sealant industries.

Analyst Insight

According to Procurement Resource, the price trend for butyl acrylate are expected to remain volatile in the upcoming quarter. The prices are estimated to suffer from low demand from the end-user industries and the weakening of the global economy.

Butyl Acrylate Price Trend for the Second Half of 2022

Asia

The price trend for butyl acrylate remained on the lower side of the scale during the second half of 2022. The covid mandated shutdowns by the Chinese government, coupled with the power rationing norms, affected industrial production. The falling upstream cost pressure owing to dwindling costs of crude oil and n-butanol further aided this plunge. The lowered demand from the downstream construction and adhesive industries amid the fears of a global recession negatively affected the buying sentiments of consumers, thereby affecting the overall pricing fundamentals of the market.

Europe

The acute energy crisis unveiled by the Russian invasion of Ukraine led to economic backlash giving rise to runaway inflation. With the unprecedented price rise of almost all commodities, the European markets suffered from demand destruction for the second half of 2022. Despite the high upstream cost pressure, the manufacturers were forced to lower their quotations given the weak demand. With the normalization of supply chains and opening of ports in the fourth quarter, no significant rise in the butyl acrylate prices was seen. Overall, the price trend for butyl acrylate kept negative.

North America

The US domestic market mimicked the global outlook in terms of prices and demand for butyl acrylate. The falling feedstock prices, oversupplied inventories, and plunging demand caused the price trend to decline. The port congestion and supply chain disruptions did not impact the market's falling fundamentals. The manufacturers actively participated in destocking to make room for new production.

Analyst Insight

According to Procurement Resource, the price trend for butyl acrylate are likely to remain negative in the coming quarter. As the supply chains stabilize and markets open for trade, the rate at which the demand rebounds (provided the other market variable holds constant) will dictate the trend for butyl acrylate.

Butyl Acrylate Price Trend For the Second Quarter of 2022

Asia

As the major Asian economies had divergent market emotions for butyl acrylate in Q2 2022, the Asian market as a whole displayed conflicting sentiments. After the pandemic restrictions were lifted China tried to return to normalcy, however the factories were not working at optimum rates. Due to the nation's zero covid policy, manufacturers in the country were always threatened by the possibility of a fresh wave of new cases, which had the potential to trigger new restrictions.

The price trend for butyl acrylate fell in the last month of the quarter after climbing for the previous two. The price of butyl acrylate was roughly 2210 USD/MT in the first week of May in China. On the other hand, the price dropped in June as a result of a lacklustre domestic and specialised customer demand.

Europe

Despite the ongoing war situation in the market, butyl acrylate prices increased throughout the quarter across the European market due to stable fundamentals in downstream sectors' demand. Because of growing feedstock values and inflationary pressure brought on by rising natural gas costs, butyl acrylate prices increased on the domestic market.

On the supply front, the German market saw constrained supplies as producers were under pressure due to decreased production rates and rising upstream prices. Furthermore, butyl acrylate prices increased in the European market due to high freight costs and ongoing logistical difficulties. The average price for butyl acrylate in April was estimated to be USD 3228 USD/MT FD Hamburg.

North America

The Butyl acrylate market was under constant inflationary pressure during the quarter as producers had to adjust their product prices to maintain profit margins. The Russo-Ukrainian war increased the upstream costs which had an impact on the pricing of several commodities on the US market, including butyl acrylate.

After the conflict intensified, a significant shift in demand for natural gas from Europe was seen, shifting from Russia to the USA. This led to a sharp increase in the price of gas on the domestic market. High natural gas prices put downstream consumers under inflationary pressure and unease throughout the market.

Analyst Insight

According to Procurement Resource, the market for butyl acrylate will remain sluggish in the upcoming quarter. With stagnant buying sentiments fueled by the speculations of global recession and pandemic-related supply disruptions in the industrial powerhouse China, acrylates prices are affected worldwide. Moreover, the low consumption levels from the electrical and paint/adhesives sector further affect the pricing patterns.

Butyl Acrylate Price Trend For the First Quarter of 2022

Asia

Butyl Acrylate saw a rise this year after seeing a steady fall in pricing during Q4 2021. The general price dynamics for the commodity across regional markets were supported by economic recovery and stable to firm offtakes. However, the conflict between Russia and Ukraine pushed up the price of upstream crude oil, affecting the cost of the feedstock acrylic acid in the region.

However, in China, lunar holidays combined with the Beijing Olympics contributed to a sharp increase in the price of a variety of goods, including butyl acrylate, in the local market. Butyl acrylate prices in India in February 2022 were roughly USD 2234/MT.

Europe

The European market is principally impacted by the Russia-Ukraine conflict, which has caused significant disruptions across the area as a result of the abrupt escalation of the war situation. The expected rise in natural gas prices, along with the rising price of crude oil, created uncertainty in the worldwide market, shaking market fundamentals for regional purchasers.

Due to their reliance on Russian natural gas, several German manufacturers have been heard opting for an energy surcharge, encouraging dealers to adjust their offerings on a regular basis. Furthermore, due to a persistent rise in crude oil value amidst disrupted trade activity along the Black Sea, the price of feedstock acrylic acid increased dramatically across the regional market. However, the price of the monomer in the European market remained stable during the quarter.

North America

Despite the pressure from global concerns, butyl acrylate prices in the US market continued to rise during the quarter. The product's demand fundamentals remained stable, but improved economies and rising input costs pushed price revisions in the North American market.

Furthermore, since WTI and Brent crude oil prices surged dramatically during this quarter, tensions between Russia and Ukraine remained a key factor in the sharp rise in prices of feedstock acrylic acid in the US market. According to the estimates, butyl acrylate prices in February hovered at 2355 USD/MT, which was still 8% lower than October pricing.

Butyl Acrylate Price Trend For the Fourth Quarter of 2021

Asia

Due to poor offtakes from the domestic market, the whole acrylic acid market in China was boring throughout this fourth quarter. Production restrictions imposed to decrease emissions already lowered downstream consumer demand, influencing the price trend of acrylic acid and its derivative chemicals, notably butyl acrylate.

Meanwhile, despite varying raw material costs, pricing in the Indian market remained low during this quarter. Due to low demand during the holiday season, dealers were heard modifying their offers in order to maintain offtakes, while raw materials were also following the declining demand trend. However, as a result of the Omicron threat, raw material prices have begun to rise. Finally, in November, the price of the monomer hovered about USD 2502/MT after a steady fall.

Europe

Throughout the fourth quarter, the European market remained stable in terms of product price movement. During October and November, an exponential rise in energy costs kept raw material prices high, but demand fundamentals varied in a small to steady range.

Long-term buoyancy was noted for butyl acrylate throughout this era, according to the research, owing to continuously shifting raw material costs in key European nations such as Germany, the Netherlands, and Russia. Despite the fact that butyl acrylate prices continued to fall during the quarter, prices in Germany remained extremely high in November, at USD 1825/MT.

North America

Butyl Acrylate market dynamics revealed conflicting feelings in the North American market, while demand fundamentals in the domestic market remained constant to solid. Raw material costs also fluctuated, whereas n-Butanol prices remained stable. Acrylic Acid pricing in the US market followed a distinct trend.

Feedstock prices had been rebounding from the effects of the February freeze, which impacted the price of its downstream products. Furthermore, during November's Asian trade, crude oil prices plummeted due to growing concerns about pandemic-related uncertainty. Finally, due to low feedstock prices, butyl acrylate prices in the US market varied in a limited range during the quarter.

Butyl Acrylate Price Trend For First, Second and Third Quarters of 2021

Asia

Because of the considerable spike in the price of feedstock acrylic acid, butyl acrylate prices in Asia saw a significant increase in Q3. Furthermore, throughout this era, the value of the monomer increased due to increased demand from downstream industries and restricted product supply. However, the Chinese market saw a drop in upstream n-Butanol pricing, which was ascribed to the producers' ease in providing bids.

Furthermore, decreased production rates as a result of China's new energy policy caused ripples across the market. As a result, the FOB Wuhu-China monthly average in September was 2868 USD/MT, an increase of 852 USD/MT over July's rates. Similarly, the market in India witnessed a strong uptick, owing to decreasing imports of the feedstock and strong demand. However, due to cheaper n-Butanol and improved imports, butyl acrylate prices fell somewhat in September. As a result, Ex-Hazira prices in July were 2887.09 USD/MT.

Europe

Early in the third quarter, certain European Acrylates companies announced maintenance shutdowns, restricting regional supplies. To make up for losses in past quarters, leading manufacturer Arkema announced an increase in EU Acrylic monomer pricing compared to the previous quarter.

ABS (acrylonitrile-butadiene-styrene) was benefiting from high margins as demand increased. Spot ABS prices were seen increasing by double digits as buyer reaction improved as the year progressed.

North America

The monomer’s price increased in the third quarter of 2021 due to high demand and constrained supply in North America. Acrylic Acid, which serves as its feedstock, had seen its price rise steadily, putting downward pressure on the monomer and its downstream products. Furthermore, by the end of August, Hurricane Ida in the United States had interrupted not only the operation of various production units, including Butanol and Acrylic Acid, but also the supply chain throughout the international market.

Dow, for example, was forced to shut down its Acrylic Acid factory in August owing to power shortages caused by Hurricane Harvey. Besides, there was considerable growth in the usage for the monomer from downstream paints, adhesives, and coatings sectors after the revival in the industrial and commercial activity which further supported this higher price trajectory in North America.

Procurement Resource provides latest prices of Butyl Acrylate. Each price database is tied to a user-friendly graphing tool dating back to 2014, which provides a range of functionalities: configuration of price series over user defined time period; comparison of product movements across countries; customisation of price currencies and unit; extraction of price data as excel files to be used offline.

About Butyl Acrylate

Butyl acrylate is a significant acrylic monomer from the acrylic esters group, which is generated from acrylic acid and used to give a wide range of polymers performance qualities.

Butyl Acrylate Product Details

| Report Features | Details |

| Product Name | Butyl Acrylate |

| Chemical Formula | C7H12O2 |

| Molecular Weight | 128.17g/mol |

| Synonyms | n-Butyl acrylate, 141-32-2, butyl prop-2-enoate, 2-Propenoic acid, butyl ester |

| Industrial Uses | Paints & coatings, Adhesives & sealants, Textiles, Plastic additives, Paper treatment |

| Supplier Database | Arkema S.A., BASF S.E, Nippon Shokubai Co. Ltd, Dowdupon Inc., LG Chem Ltd., Taogosei Co. Ltd., Mitsubishi Chemical Corporation, SunVic Chemical Holdings Corporation |

| Region/Countries Covered | Asia Pacific: China, India, Indonesia, Pakistan, Bangladesh, Japan, Philippines, Vietnam, Iran, Thailand, South Korea, Iraq, Saudi Arabia, Malaysia, Nepal, Taiwan, Sri Lanka, UAE, Israel, Hongkong, Singapore, Oman, Kuwait, Qatar, Australia, and New Zealand Europe: Germany, France, United Kingdom, Italy, Spain, Russia, Turkey, Netherlands, Poland, Sweden, Belgium, Austria, Ireland Switzerland, Norway, Denmark, Romania, Finland, Czech Republic, Portugal and Greece North America: United States and Canada Latin America: Brazil, Mexico, Argentina, Columbia, Chile, Ecuador, and Peru Africa: South Africa, Nigeria, Egypt, Algeria, Morocco |

| Currency | US$ (Data can also be provided in local currency) |

| Supplier Database Availability | Yes |

| Customization Scope | The report can be customized as per the requirements of the customer |

| Post-Sale Analyst Support | 360-degree analyst support after report delivery |

Note: Our supplier search experts can assist your procurement teams in compiling and validating a list of suppliers indicating they have products, services, and capabilities that meet your company's needs.

Butyl Acrylate Production Processes

- Butyl Acrylate Production from Acrylic Acid and n-Butanol via Esterification; Butyl Acrylate Production from Propylene and n-Butanol via Propylene Oxidation

Via Esterification: In this process, butanol and acrylic acid undergo a reaction in a reactor in the presence of an esterification catalyst. The water produced is entrained via distillation in a column, leaving the desired product, i.e., butyl acrylate.

Methodology

The displayed pricing data is derived through weighted average purchase price, including contract and spot transactions at the specified locations unless otherwise stated. The information provided comes from the compilation and processing of commercial data officially reported for each nation (i.e. government agencies, external trade bodies, and industry publications).

Assistance from Experts

Procurement Resource is a one-stop solution for businesses aiming at the best industry insights and market evaluation in the arena of procurement. Our team of market leaders covers all the facets of procurement strategies with its holistic industry reports, extensive production cost and pre-feasibility insights, and price trends dynamics impacting the cost trajectories of the plethora of products encompassing various industries. With the best analysis of the market trends and comprehensive consulting in light of the best strategic footstep, Procurement Resource got all that it takes.

Client's Satisfaction

Procurement Resource has made a mark for itself in terms of its rigorous assistance to its clientele. Our experienced panel of experts leave no stone unturned in ensuring the expertise at every step of our clients' strategic procurement journey. Our prompt assistance, prudential analysis, and pragmatic tactics considering the best procurement move for industries are all that sets us apart. We at Procurement Resource value our clients, which our clients vouch for.

Assured Quality

Expertise, judiciousness, and expedience are the crucial aspects of our modus operandi at Procurement Resource. Quality is non-negotiable, and we don't compromise on that. Our best-in-class solutions, elaborative consulting substantiated by exhaustive evaluation, and fool-proof reports have led us to come this far, making us the ‘numero uno' in the domain of procurement. Be it exclusive qualitative research or assiduous quantitative research methodologies, our high quality of work is what our clients swear by.

Table Of Contents

Our Clients

Get in Touch With Us

UNITED STATES

Phone:+1 307 363 1045

INDIA

Phone: +91 8850629517

UNITED KINGDOM

Phone: +44 7537 171117

Email: sales@procurementresource.com