Product

Phenol Price Trend and Forecast

Phenol Price Trend and Forecast

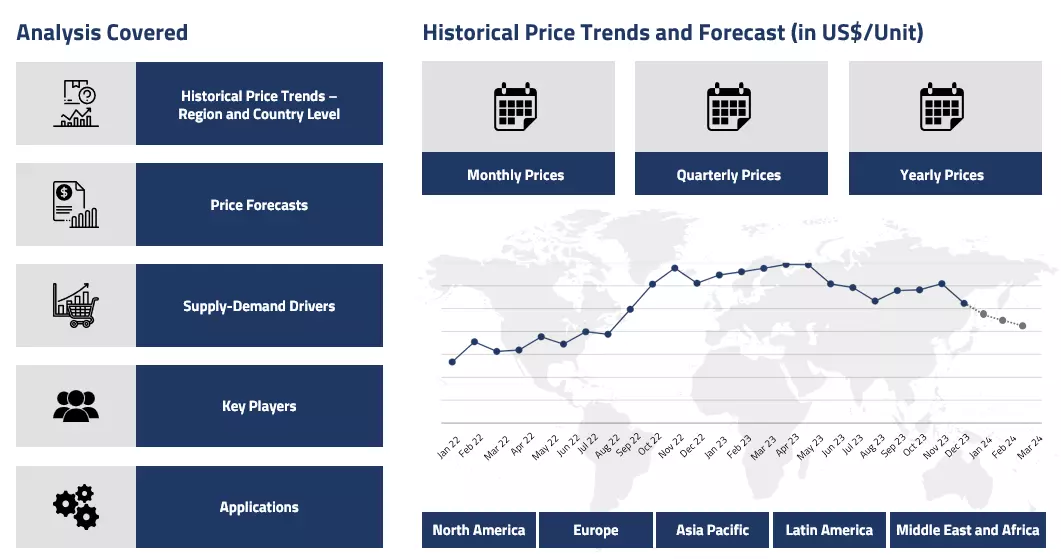

Phenol Regional Price Overview

Get comprehensive insights into the Phenol market, with a focused analysis of the Phenol price trend across Asia, Europe, North America, Latin America, and the Middle East & Africa.

Phenol Price Trend for Q1 of 2025

| Product | Category | Region | Price | Time Period |

| Phenol | Chemicals | India | 989 USD/MT | January'25 |

| Phenol | Chemicals | India | 976 USD/MT | March'25 |

| Phenol | Chemicals | North America | 1122 USD/MT | January'25 |

| Phenol | Chemicals | North America | 1145 USD/MT | March'25 |

Stay updated with the latest Phenol prices, historical data, and tailored regional analysis

Asia

Phenol prices trend in the Asian region, particularly in India, had a rough start in the first quarter of 2025, with a steady drop in the first two months of the quarter. Demand was sluggish as industries like automotive and construction held off on big purchases due to seasonal slowdown around the annual budget declaration.

Phenol Price Chart

Please Login or Subscribe to Access the Phenol Price Chart Data

The Phenol price trend reflected this weak buying sentiment, keeping prices under pressure. Still, by the mid-February mark, the market began picking up as downstream segments—mainly adhesives, laminates, and phenolic resins—placed new orders. These events supported the phenol price rise marginally, yet the market was still overall quite volatile. Towards the end of the quarter, supply and demand both established a kind of equilibrium, resulting in a stable price trend. The phenol prices ended the quarter at a lower level compared to the beginning. The monthly average prices were about 989 USD/MT in January and around 976 USD/MT in March in the Indian markets.

Europe

The European phenol market struggled with the prices of Phenol remaining weak in the first quarter. Some enthusiasm was witnessed as the downstream industries reopened after the New Year Holidays. However, as the quarter progressed, the demand from consuming sectors such as construction and automotive was slow. Buyers were not anxious to replenish their stocks, and this kept prices at a standstill for most of the quarter. In addition to that, oversupply from expanded production within Asia also exerted pressures on the market.

The Phenol price graph hardly shifted, apart from a slight rise in February when prices for benzene increased. Germany's economic slowdown further added to the volatility, lowering the demand for phenolic resins used in building materials, insulation, and furniture. The European Phenol price chart reflected negative market sentiment, showing limited price movement with occasional fluctuations.

North America

In North America, Phenol prices exhibited a stable and gradually increasing trend in the first quarter of 2025. The monthly average price stood at approximately 1122 USD/MT in January and reached around 1145 USD/MT by March. Prices saw a measured rise early in the year, supported by firm feedstock costs and steady demand from the downstream sector.

According to the Phenol price database, buyers maintained cautious inventory building, anticipating sustained market strength. The adhesives, coatings, and plastics industries continued to drive stable demand, while energy costs and raw material expenses contributed to moderate price support. By the end of the quarter, supply and demand found a balance, leading to price stabilization. The Phenol price chart reflected a well-supported market, with an initial phase of growth followed by a steady close to the quarter.

Analyst Insight

According to Procurement Resource, the Phenol price curve is expected to remain within a narrow range in the near future, since not much change is anticipated in the current supply and demand outlooks.

Phenol Price Trend for Q4 of 2024

| Product | Category | Region | Price | Time Period |

| Phenol | Chemicals | India | 1,179 USD/MT | October'24 |

| Phenol | Chemicals | India | 1,139 USD/MT | December'24 |

| Phenol | Chemicals | North America | 1,116 USD/MT | October'24 |

| Phenol | Chemicals | North America | 1,092 USD/MT | December'24 |

Stay updated with the latest Phenol prices, historical data, and tailored regional analysis

Asia

The prices of Phenol in the Asian region exhibited regional variations during the fourth quarter of 2024. In India, Phenol prices fluctuated within a narrow range at the beginning of the period but later followed a gradual downward trend. In October, the monthly average price in the Indian market stood at approximately 1,179 USD/MT, declining to around 1,139 USD/MT by December.

This decrease was driven by an increased supply, supported by steady vessel arrivals and the resumption of operations at major production facilities like Deepak Phenolics, leading to a market surplus. Additionally, lower feedstock costs, resulting from a decline in Crude Oil and Naphtha prices, reduced production expenses, further exerting downward pressure on Phenol prices. Despite expectations of seasonal demand growth from plywood manufacturers, bulk buyers remained cautious about stockpiling inventories due to ongoing weakness in upstream markets.

Consequently, the Phenol market faced persistent downward pressure throughout the quarter. In China, Phenol prices also declined during the quarter, primarily due to a weakened upstream market and increased production levels. Ample domestic supply led to bearish market sentiment, prompting suppliers facing high inventory levels to offer price reductions to stimulate sales. However, downstream buyers remained focused on fulfilling only essential demand. This cautious approach from end-user companies further restricted overall demand, preventing any significant recovery in the Phenol market.

Europe

The European Phenol market mirrored the trends observed in Asian markets during Q4'24, displaying an overall declining trend with intermittent periods of stagnation. The European construction sector has been struggling for some time, initially due to the Covid pandemic and later exacerbated by the impact of the Russia-Ukraine conflict, both of which weakened consumer purchasing power. This sustained weak demand for downstream Phenol-derived products such as phenolic resins. Additionally, fluctuating downward prices of feedstocks like crude oil and naphtha kept the upstream markets consolidated.

North America

The Phenol price curve exhibited varied pricing patterns in the North American markets during the fourth quarter of 2024. Initially, prices followed a stable upward trend as demand increased ahead of the holiday season due to stockpiling activities by some traders. Broader market stability was also supported by the presidential elections in the United States.

However, as the quarter progressed, prices declined, influenced by a downturn in global crude oil prices. Long-term demand in the downstream sector, particularly the polycarbonate industry, remained muted. Additionally, a weak construction sector and political uncertainties before the elections led to a cautious market sentiment. Prices stood at approximately 1,116 USD/MT in October and declined to around 1,092 USD/MT in December. Overall, the Phenol market experienced a fluctuating trajectory in Q4'24.

Analyst Insight

According to Procurement Resource, the prices of Phenol are expected to show a similar pricing pattern unless supply conditions change in the market. Downstream demands also don’t suggest much change in the immediate future.

Phenol Price Trend for Q3 of 2024

| Product | Category | Region | Price | Time Period |

| Phenol | Chemicals | India | 1207 USD/MT | July'24 |

| Phenol | Chemicals | India | 1187 USD/MT | September’24 |

| Phenol | Chemicals | North America | 1102 USD/MT | July'24 |

| Phenol | Chemicals | North America | 1145 USD/MT | September’24 |

Stay updated with the latest Phenol prices, historical data, and tailored regional analysis

Asia

In Q3 2024, the phenol market experienced notable fluctuations due to tight supply conditions and regional demand variations. Early in the quarter, low inventories at Jiangyin Port prompted traders to raise prices. Throughout August, the market remained constrained as domestic cargo arrivals and export shipments further tightened supply, leading to steady price increases in East and North China. However, terminal enterprises showed caution, primarily replenishing stocks rather than pursuing aggressive buying. As September progressed, inventory levels remained low, sustaining upward pressure on prices, influenced by rising crude oil costs.

The situation in the Indian phenol market was also not very different, prices were found fluctuating here as well. Prices in the phenol market remained volatile, reflecting a well-supplied environment that was offset by weak demand from downstream industries, such as laminates and agrochemicals. This reduced demand adversely impacted pricing trends in the early months as the prices saw some depreciation in the first half of the quarter; however, as the demands started aligning in the later days, the prices started recovering in the second half of the quarter. The spot price in India went from approximately 1207 USD/MT in July to approximately 1187 USD/MT in September’24. Overall, mixed market dynamics were witnessed.

Europe

The prices of phenol in the European market were observed reflecting similar trends as its global counterparts. Even though the quarter had a strong start attributed to various logistical and supply challenges, the downstream demand remained below the desired levels and showed no signs of recovery. As the quarter progressed the supply chain hindrances also got better. Phenol is majorly used as a feedstock material to prepare different resins which are used in the construction sector.

However, the troubled European real estate sector slowed down the demand for resins. The declining prices of benzene played a limited role in determining the price trajectory of the phenol as the demand from downstream sectors, such as petrochemicals and automotive industries, kept the market moderately driven. The downstream buyers were cautious in accepting higher prices and purchased only the needed amount. Overall, dull market activity was observed in the phenol sector during the third quarter of 2024.

North America

The prices of phenol in North American market fluctuated positively for the majority of the given time period. The prices increased stood at approximately 1102 USD/MT in July and with a positive supply and demand balance inclined substantially in the first half of Q3’24. However, after remaining steady for the whole of August, some retraction was seen in the later days of September. However, the market sentiments still remained intact owing to a positive supply and demand interplay. After mildly sliding in the second half of the quarter, the average monthly prices for phenol reached about 1145 USD/MT in September of 2024. Overall, mixed market performance was witnessed.

Analyst Insight

According to Procurement Resource, the price of phenol is expected to show a marginal fluctuating trend in the coming months as the regional attributes do not exhibit any drastic changes.

Phenol Price Trend for Q2 of 2024

| Product | Category | Region | Price | Time Period |

| Phenol | Chemicals | China | 1061 USD/MT | April'24 |

| Phenol | Chemicals | China | 1124 USD/MT | May'24 |

| Phenol | Chemicals | India | 1134 USD/MT to 1203 USD/MT | Q2'24 |

Stay updated with the latest Phenol prices, historical data, and tailored regional analysis

Asia

In Q2'24, phenol prices in China experienced a stable upward trend as the monthly average of the prices increased from 1061 USD/MT in April to 1124 USD/MT in May. The market was strong, driven by limited domestic supply and moderate purchasing interest from the terminal market. Despite average production, the reduced supply pressure allowed for gradual price increases. Sinopec's price adjustments also contributed to market support, with traders pushing up prices and end-user industries complying with this surge. Although downstream, bisphenol A saw fluctuations with some price increases, overall trading volumes remained limited.

The pure benzene market experienced slight declines, adding to the cautious market sentiment. Similarly, in India, the price of phenol marginally rose from approximately 1134 USD/MT to 1203 USD/MT in the second quarter. In this region, too, the trend was stabilized by the striking balance of the supply and demand sectors and the rising cost of production.

Europe

In Q2'24, phenol prices in the domestic market of Germany experienced an upward trend, primarily driven by the increasing prices of its upstream raw material, benzene, influenced by rising international crude oil prices. This rise was further supported by the expectation of a decline in crude oil stocks due to a seasonal increase in global demand and extended production cuts by OPEC+.

Despite the average demand from downstream construction industries, moderate procurement of phenol from other downstream sectors was observed. Also, manufacturing facilities operated at slightly reduced rates, balancing sufficient stock availability of the commodity. Several market players indicated significant investments in this sector as the investors anticipated a rise in demand growth for phenol in automotive and other industrial sectors.

North America

In the second quarter of 2024, phenol prices in the USA remained relatively stable despite fluctuations in the chemicals industry. The demand from the domestic construction and automotive sectors was only moderate. However, the Chinese market showed average demand for phenol, which was catered by ample stock availability and smooth functioning of supply chains.

The upstream raw material costs, on the other hand, extended major support, maintaining a steady market. Additionally, globally, crude oil prices saw a rise following OPEC+'s decision to maintain production limits, raising production costs. The rise in production costs was further driven by the expanding cost of raw materials, contributing to bullish sentiment in the Phenol market. However, the overall demand from downstream industries, such as Bisphenol A, was limited, which tempered any substantial price increase.

Analyst Insight

According to Procurement Resource, the price trend of Phenol is expected to follow the trail set by rising prices of feedstock commodities and increased rates of procurement from the end-user industries.

Phenol Price Trend for Q1 of 2024

Asia

Market sentiments in the Asian region were quite positive for phenol. Suppliers were consistent and ordered well, as the new year began on a firm note. Markets were seen inclining in both India and China as petroleum prices rose in the international markets. Russia and Iraq, two prominent members of OPEC+, faced some output decline, which eventually reflected in the whole petrochemical industry.

In the Indian phenol market, the prices went from about 1014 USD/MT in January’24 to around 1055 USD/MT in March’24. This led the Indian phenol market to incline by about 4% as the consumption too supported this growth. The downstream construction and chemical industries put forward stable demands supporting the positive growth in the regional phenol market. Overall, a rising trajectory was witnessed in Q1’24.

Europe

The European phenol market was not much different from the Asian market as the prices were observed to be in line here as well. Ukraine attacked the major Russian oil refineries, which affected the region’s energy infrastructure significantly. Russian oil output dipped by about 7% as the operations got hurdled.

The downstream demands were stable and rose steadily, which provided more push to the growing price trajectory. Europe also had to rely more on imports as many producers held off on increasing production. The geopolitical situation in the Red Sea has also impacted the market, with Middle Eastern producers facing logistical challenges.

North America

Contrary to the global trend, phenol prices observed a slight fall in the American markets during the first quarter of the year 2024. Because of the logistic issues in the Red Sea with rising Houthi attacks and the war crisis in the Middle East, export queries were facing a steady decline. In the USA, the monthly average prices stood at around 1163 USD/MT in January’24 and then receded to about 978 USD/MT in March of 2024. This caused an approximate depreciation of about 15% in the US phenol price trajectory. Overall, muted market sentiments were observed.

Analyst Insight

According to Procurement Resource, the Phenol price trends are likely to continue varying in the coming months as well. Given the current macroeconomic indicators, different markets will respond differently to the ongoing geopolitical disturbances.

Phenol Price Trend for October - December of 2023

Asia

The Asian phenol markets observed variations in price trends throughout the last quarter of the year 2023. The Indian phenol market started strong in October as the prices witnessed a notable rise from September to October. However, as the months progressed, the bulked-up inventories started influencing the market trends, and the market wavered downwards.

Despite some occasional upward fluctuations, the Indian domestic phenol market observed an overall downfall of around 11% as the monthly average spot prices went from around 1160 USD/MT in October to about 1028 USD/MT in December’23. Because of the high demand and upsurge in prices in previous months, suppliers made bulk purchases, anticipating higher revenues. However, the demands almost plateaued beyond a point, and the suppliers were almost forced to discount the prices in order to maintain the stock momentum. Despite this, the regional projections look promising for the coming months.

Europe

Compared to the other major phenol markets, the European market saw depreciating trends during the fourth quarter of the year 2023. A high number of stocked units in inventories and a major fall in the downstream demands drove these price trends negatively. The Christmas holiday season is another reason for the economic slowdown. However, the market demands fell to unprecedented levels. Overall, weak market sentiments were observed.

North America

The North American phenol market performed really well on the price front during the given period of time. In the US market, the monthly average spot prices went from around 1130 USD/MT in October’23 to around 1319 USD/MT in December’23. The impending holiday season called for higher industrial activity in the early months; hence, the prices showed a significant rise throughout the discussed period. In line with the above trends, the prices are expected to average around 1335 USD/MT in January’24.

Analyst Insight

According to Procurement Resource, the market projections for Phenol are varying. Prices are expected to vary regionally as per the regional supply and demand situations.

Phenol Price Trend for July - September of 2023

Asia

The upstream market of phenol showcased significant growth along with the downstream industries, which helped in the rise in the phenol price graph. The upward swing in the phenol price trend was also affected by the increase in crude oil prices and its limited supply. In addition to this, the bullish nature of phenol prices was also supported by a contraction in manufacturing activities and disrupted availability of the product in the market.

Europe

The third quarter of 2023 witnessed a slump in the procurement rates of phenol, and thus, in the European countries, the phenol price trend moved southwards. The downfall of the phenol prices was the consequence of weak demand and the declining cost of its feedstock materials. Additionally, the exponentially rising cost of energy production became a challenge for the producers, and with feeble market dynamics of phenol and excessive inventories, the phenol price graph took a downward turn.

North America

The downstream industries presented moderate demand in the third quarter of 2023, but it was not sufficient to keep the phenol price trend afloat. During this phase, the manufacturers struggled with the lowering of prices of feedstock materials and the poor purchasing attitude of the consumers. However, as compared to the previous quarter, the speed of inflation slowed down, and as the quarter progressed, the upstream market started to show some signs of improvement, positively influencing the phenol price trend.

Analyst Insight

According to Procurement Resource, the price trend of Phenol are expected to trace a volatile trend in the upcoming quarters as the surge in the cost of crude oil in accordance with OPEC+ restrictions and fluctuating demand will be a challenge for phenol prices.

Phenol Price Trend for the First Half of 2023

Asia

The price trend for Phenol recorded a declining pattern in the first half of 2023. In China, the spot prices went from around 1295 USD/MT in January to around 1125 USD/MT in June’23. The lowered demands due to the economic downturn negatively impacted the pricing fundamentals. However, minor fluctuations were seen in the market around February as the hoarding sentiment of buyers was on the rise, given the approaching holiday season of low productivity. But soon, the market turned to its previous rates, thereby affecting the prices.

A similar trend was observed in India, where the phenol price almost seemed flat for most of H1’23. Nonetheless, the phenol prices started actively declining towards the end of the second quarter. The stagnant market dynamics and lowered upstream cost pressure could not sustain a healthy price rise. The spot price of Phenol averaged around 1048 USD/MT in June’23.

Europe

The European phenol market had a slow start in early Q1. But soon, the market picked up pace, and the phenol prices started rising with a gentle inclination. The rise in feedstock benzene prices raised the production costs pushing up the prices, which, coupled with rising offtakes from downstream paints and coating industries, aided the price hike.

North America

The price trend for Phenol continued upward during the first half of 2023 in the US domestic market. The rising upstream cost pressure, given the increased prices of feedstock benzene, provided the necessary support for high prices. Further, the inclining demand from the downstream sectors aided this new-found momentum. The spot prices of Phenol went from around 1140 USD/Mt in January to around 1315 USD/MT in June’23.

Analyst Insight

According to the Procurement Resource, Phenol prices will likely remain unsettled in the coming quarter. The price trend are expected to exhibit mixed patterns given the regional imbalances in the global market; however, the downstream demand will remain a major driving force behind the phenol market, keeping the other variables constant.

Phenol Price Trend for the Second Half of 2022

Asia

Phenol prices showed mixed sentiments for the second half of the year 2022. The Chinese market was still recovering from the lockdown, and industrial activities remained muted. Hence the phenol prices kept declining for most of Q3. The market gained a little momentum at the end of the third quarter. Soon the freight costs and port congestions normalized, reducing the upstream cost pressure. The market strived for equilibrium, which further drove down the prices. The stagnant downstream demands, coupled with lowered upstream costs, kept the phenol prices on the lower end of scale throughout the fourth quarter.

Europe

The economic uncertainties created by the Russia-Ukraine war, coupled with high energy prices, significantly impacted European consumer behavior. This change kept the phenol prices on a declining trajectory throughout the second half of 2022. The purchase became more essential-centric in Europe. The end-user demand from the adhesive, paint, and chemical industries reduced considerably. With the normalization of supply chains, as substitute products from the Middle East and Africa entered the market, the feeble demand could not sustain stable market dynamics, causing the phenol prices to fall further.

North America

In the North American market, phenol prices witnessed fluctuating trend. The prices continued downward for most of the second half but gained a bit towards the end months of 2022. Low demand amid difficult freight and supply situations kept the market sentiments low. As the supply situations improved and industrial activities resumed, the prices in the ending months improved temporarily.

Analyst Insight

According to the Procurement Resource, the phenol prices are expected to remain low swinging as the demand dynamics seem to be weak. Given the trade normalization, rising consumer offtakes will remain the driving factor for the phenol market.

Phenol Price Trend For Second Quarter of 2022

Asia

The price trend for Phenol exhibited an oscillating movement in the Asia-pacific region during the said period. Owing to the zero-tolerance covid-19 protocols, industrial production in the Chinese domestic market was severely hampered.

Also, the high feedstock benzene and cumene prices further impacted the prices, and thus the demand suffered. However, towards the end of the second quarter, the prices began to stabilize and incline as the restrictions were lifted and factories resumed new production. The price of Phenol averaged 1660 USD/MT towards the end of Q2.

Europe

Phenol prices increased dramatically in the European region due to the high crude oil and natural gas prices. With the EU announcing an embargo on Russian oil along with retaliatory sanctions against Russian exports, a massive energy crisis engulfed the European markets. High feedstock prices coupled with downstream solid demand for phenolic resins reinforced the high costs of Phenol averaging 2100 USD/MT.

North America

The US domestic market registered mixed sentiments for phenol pricing in the said period. Initially, the prices declined as the upstream cost pressure relaxed due to the stabilizing crude oil and gas prices. The lowered demand forms the market led to stockpiling of products in the market. Towards the end of said period, prices rebounded and inclined slightly as healthy market sentiments ensured sufficient offtakes from the market.

Analyst Insight

According to Procurement and Resource, phenol prices are likely to remain anchored in their respective markets. As the upstream cost pressure relaxes, the final say will come down to the demand aspect part of the market dynamics, which presently remains bearish.

Phenol Price Trend For First Quarter of 2022

Asia

The phenol market in China declined first, then rebounded, and then fell again in March 2022. China's mainstream factories jointly raised market sentiment in early March. The price was roughly 10637.5 RMB/MT on March 31, 2022.

The chemical is primarily employed as a precursor in the production of significant industrial chemicals. Because its chemical structure is made up of firmly connected hydroxy and phenyl groups, its functional properties are comparable to those of alcohol. As a result, it is often employed as a basic ingredient in commercial house cleaning solutions.

Phenol Price Trend For Fourth Quarter of 2021

Asia

In the final quarter of 2021, the market sentiments were drifting since the festive season in October. The supply in India had improved after increased availability in China following the energy crisis in the region.

As margins were diminishing, a turnaround was imposed by Hindustan Organics at its phenol and acetone plant in India during mid-November. The prices rose phenomenally owing to the delayed resumption of operations at Hindustan Organics Phenol Plant. In the late December, phenol prices once again started to witness a drift due to a weak demand in the international markets for the product.

The demand in India had been somewhat stagnant and market players were adjusting their revisions in the prices to clear the excess stocks as the year end approached In India, amidst the narrow demand, phenol prices were close to 1480 USD/MT in December.

Europe

In the last two months of the final quarter of 2021, the prices in Europe had consistently declined. In the beginning of the quarter, the freight rates and supply chain disruption had stabilized, but the energy crisis in the region allowed high operating costs.

The demand for the chemical had remained dull, as inquiries fell because of the year end slowdown, even though manufacturing costs were firm. This weak demand and excess supply caused the prices to tumble at around 1725 USD/MT in December.

North America

In the final quarter of 2021, North America had witnessed a constant decline in demand as supply improved appreciably. In quarter 3, the supply was restored gradually after the Ida hurricane as plant operations were resumed. The plant operating capacities returned close to the normal levels by the final quarter which led to an ample supply of the product.

The demand dropped due to seasonal slowdown in the region for solvents from paints, coatings and automotive sector. The inventories had also build-up in several countries due to which export demand remained low. By the end of December 2021, however, the demand stabilized the downward trajectory of phenol in the domestic markets. In the US, FOB phenol prices were recorded at 1470 USD/MT in December.

Phenol Price Trend For First, Second and Third Quarters of 2021

Asia

In the beginning of the first quarter, the supplies in Asia improved as maintenance turnaround periods ended in several manufacturing facilities. The supplies, however, remained tight as most operations were curtailed by the advent of the Chinese Lunar Year.

The demand remained firm as the market observed a replenishment of stocks in mid-March, which was followed by a surge in demand from phenolic resin manufacturers. Acetone, which is a by-product of phenol, also witnessed high demands. The domestic phenol prices were thus driven up by the surge in demand while supplies were moderate. In India, the average prices in the first quarter of 2021 were around 1204 USD/MT and the CFR prices were 1016 USD/MT.

The Asia Pacific region witnessed a mixture of sentiments for the phenol market outlook in the second quarter of 2021. The second wave of Covid-19 had a devastating impact in several states of India but in spite of this the local phenol market demand remained mostly firm. Several producing facilities in the northeast regions of China had turnarounds which curtailed the supplies of the chemical significantly in the region.

Mitsui Chemical Phenol facility in Sakai, Japan and Kumho P&B Line 3 in South Korea had been shut down temporarily for maintenance purposes in the months of May and June. The demand in China remained strong in the second quarter as the economies expanded and downstream demand from automotive and construction industries rose. The price trend witnessed an upward slope as the upstream benzene prices surged to record highs.

The FOB Dalian phenol prices were 1555 USD/MT in June. In the third quarter of 2021, several phenol plants in Asia and Europe had been going off stream as they faced challenges in operations which affected the supply fundamentals of the product in the region. The government in China imposed dual-energy norms which directed several plants to maintain low operating costs, which restricted the supply in China in September.

The downstream industries which included construction and automotive sectors maintained consistent demands for phenol in quarter 3. The Indian markets experienced strong demand as producers continued to operate at optimum efficiencies to keep up with the local demand as global supplies of phenol dwindled. In the third quarter, phenol prices in India went from 1524 USD/MT to 1608 USD/MT.

Europe

The supplies in Europe were mostly constrained in the first half of the first quarter in 2021 as a result of turnarounds in several manufacturing facilities for maintenance and also the slowdown in activities in both commercial and industrial channels due to the onset of the second wave of Covid-19, which had caused a slump in the European economy as lockdowns were imposed. Nevertheless, the demand from the downstream industries was still high as the automotive sector witnessed recovery.

The phenolic resin offtakes were also good as demands increased from the construction sector in the beginning of the first quarter. The supplies were tightened in Europe in the second quarter of 2021 due to the turnarounds in most manufacturing facilities. Inflows improved from the US which eased the import supplies.

The construction sector pushed the demand for phenol due to the seasonal requirements, while the demands from downstream sectors like automotive also increased marginally in the second quarter. Phenol prices in Europe observed an upward trajectory amidst the erratic supply and demand fundamentals and the inflation of upstream benzene prices in the global market.

The revival in downstream industries was forecasted as vaccination programs were being promoted. In the third quarter of 2021, the price trend in Europe witnessed a downward slope. The domestic prices fell, following the price slump in the upstream benzene while the feedstock supply eased during the same time which caused phenol prices to go down in the third quarter. The Hamburg FD prices dropped from 1710 USD/MT in July to 1485 USD/MT in September.

North America

Phenol prices were impacted significantly in the first half of the quarter 1 in 2021 due to the turnarounds at plants as turnarounds in the upstream cumene plants led to a feedstock shortage.

The US Gulf region experienced harsh weather conditions which led to production outages which in turn resulted in a spike in phenol prices. The US-based Olin Corp had shut down in February, which also affected the market supplies. An extensive infrastructure plan allowed the growth of the non-residential sector, which affected the performance of the housing sector, driving up the demand.

In March, the CFR Texas prices soared high at 2570 USD/MT. A substantial amount of supplies were directed to Europe as global supplies tightened. In North America, the overall outlook for the phenol market had improved as industries recovered in the US Gulf Coast in the second quarter of 2021.

Several production units restarted with better operating rates and the increased supply of upstream benzene allowed phenol supplies to pick up pace in the region, even though a few suppliers were unable to operate their production facilities for phenol at normal rates.

The demand began to rise significantly from downstream industries such as the production facilities of Epoxy resin, Nylon and Polycarbonate which experienced high consumer demand. While the demand from the automotive sector remained slow, the major market was being driven by the demands from the building and construction sectors. In North America, FOB Texas prices eased at 1635 USD/MT in June. In the third quarter of 2021, phenol prices remained stable in North America.

The supply and demand dynamics in the industry had improved, as producers were able to restore their production capacities close to the pre-storm levels. Phenol prices in quarter 3 had dropped from those in quarter 2. The reported phenol prices in Texas were around 1280-1320 USD/MT in August. Building, construction and automotive sectors also observed high demands throughout the quarter.

Phenol Price Trend For the Year 2020

Asia

The phenol market in Asia remained dull as supplies overflowed with massive capacities of 400 KTPA in Zhejiang Petrochemicals, China. The situation was further attenuated as operations resumed in Mitsui Chemicals, Japan and Chung Chun PC, China with no known intentions of turnarounds till the quarter end. The manufacturers in the North Asia region were operating at maximum possible capacities. However, the inventories were being consumed with offtakes for derivatives.

Europe

The phenol downstream industries made no significant gains which reduced its demand in the region amid supply surpluses. Most manufacturers curtailed production as a response of the supply overhang. The market in Europe experienced dull offtakes, even though major manufacturers like Seqens and Domo Caproleuna went through a maintenance turnaround.

The coronavirus resurged in the area which impacted the demand for phenol derivatives like Caprolactam and Bisphenol A in the automotive sector which ultimately reduced the overall demand for the chemical with no hopes for recovery in 2020.

North America

The market was balanced in North America as leading manufacturers like Shell and SABIC implemented turnarounds which outstripped the surplus supplies. The Asian market was already overflowing with the supplies after China contributed massive additions, which thus distinguished the export potential for North America as it reduced the demand from major consumers.

The downstream industries of phenol, like construction and automotive, showed promising recovery but the traders were careful about the demand dynamics and uncertainties due to the consistently rising coronavirus cases in the region.

Latin America

In 2020, the Brazil phenol industry experienced a demand of 126.8 thousand tonnes. During the covid-19 pandemic, several end-user industries were shut down due to the lockdown which had severely impacted the demand in Brazil along with supply chain disruptions and trade barriers due to the restrictions in transport facilities.

Procurement Resource provides latest prices of Phenol. Each price database is tied to a user-friendly graphing tool dating back to 2014, which provides a range of functionalities: configuration of price series over user defined time period; comparison of product movements across countries; customisation of price currencies and unit; extraction of price data as excel files to be used offline.

About Phenol

Phenol is both a manufactured chemical as well as a natural substance. It belongs to aromatic group. It can be a colourless-to-white solid in its pure form. Phenol has a distinct odour which is sickeningly sweet and tarry. It is a crucial commercial commodity and is used as an intermediate to produce bisphenol A.

Phenol Product Details

| Report Features | Details |

| Product Name | Phenol |

| Industrial Uses | Abrasives, Adhesives and sealant chemicals, Finishing agents, Flame retardants, Intermediates, Ion exchange agents, Laboratory chemicals, Plasticisers |

| Chemical Formula | C6H6O |

| Synonyms | 108-95-2, Carbolic acid, Hydroxybenzene, Phenic acid |

| Molecular Weight | 94.11g/mol |

| Supplier Database | Shell Chemical Co, INEOS Phenol GmbH, Compañía Española de Petróleos, S.A.U., Mitsui Chemicals Inc., Kumho P&B Chemicals, Inc., LG Chem Ltd., Taiwan Prosperity Chemical Corporation, Honeywell International Inc., Solvay SA |

| Region/Countries Covered | Asia Pacific: China, India, Indonesia, Pakistan, Bangladesh, Japan, Philippines, Vietnam, Iran, Thailand, South Korea, Iraq, Saudi Arabia, Malaysia, Nepal, Taiwan, Sri Lanka, UAE, Israel, Hongkong, Singapore, Oman, Kuwait, Qatar, Australia, and New Zealand Europe: Germany, France, United Kingdom, Italy, Spain, Russia, Turkey, Netherlands, Poland, Sweden, Belgium, Austria, Ireland Switzerland, Norway, Denmark, Romania, Finland, Czech Republic, Portugal and Greece North America: United States and Canada Latin America: Brazil, Mexico, Argentina, Columbia, Chile, Ecuador, and Peru Africa: South Africa, Nigeria, Egypt, Algeria, Morocco |

| Currency | US$ (Data can also be provided in local currency) |

| Supplier Database Availability | Yes |

| Customization Scope | The report can be customized as per the requirements of the customer |

| Post-Sale Analyst Support | 360-degree analyst support after report delivery |

Note: Our supplier search experts can assist your procurement teams in compiling and validating a list of suppliers indicating they have products, services, and capabilities that meet your company's needs.

Phenol Production Process

- Production of Phenol via Benzene and CG Propylene; via Cumene; via Toluene; and via Benzene

The production of phenol from toluene is basically an oxidation process. This reaction is carried out in a liquid phase and toluene is further processed to form benzoic acid as an intermediate in the production of Phenol.

Methodology

The displayed pricing data is derived through weighted average purchase price, including contract and spot transactions at the specified locations unless otherwise stated. The information provided comes from the compilation and processing of commercial data officially reported for each nation (i.e. government agencies, external trade bodies, and industry publications).

Assistance from Experts

Procurement Resource is a one-stop solution for businesses aiming at the best industry insights and market evaluation in the arena of procurement. Our team of market leaders covers all the facets of procurement strategies with its holistic industry reports, extensive production cost and pre-feasibility insights, and price trends dynamics impacting the cost trajectories of the plethora of products encompassing various industries. With the best analysis of the market trends and comprehensive consulting in light of the best strategic footstep, Procurement Resource got all that it takes.

Client's Satisfaction

Procurement Resource has made a mark for itself in terms of its rigorous assistance to its clientele. Our experienced panel of experts leave no stone unturned in ensuring the expertise at every step of our clients' strategic procurement journey. Our prompt assistance, prudential analysis, and pragmatic tactics considering the best procurement move for industries are all that sets us apart. We at Procurement Resource value our clients, which our clients vouch for.

Assured Quality

Expertise, judiciousness, and expedience are the crucial aspects of our modus operandi at Procurement Resource. Quality is non-negotiable, and we don't compromise on that. Our best-in-class solutions, elaborative consulting substantiated by exhaustive evaluation, and fool-proof reports have led us to come this far, making us the ‘numero uno' in the domain of procurement. Be it exclusive qualitative research or assiduous quantitative research methodologies, our high quality of work is what our clients swear by.

Related News

Table Of Contents

Our Clients

Get in Touch With Us

UNITED STATES

Phone:+1 307 363 1045

INDIA

Phone: +91 8850629517

UNITED KINGDOM

Phone: +44 7537 171117

Email: sales@procurementresource.com

.webp)