MMAtwo Recycling Project Continues Despite Recession Woes

The European Union has given the go-ahead to the researchers of the MMAtwo recycling project, to move ahead and continue their research in order to find a suitable way to recycle PMMA (poly(methyl methacrylate)), despite the world’s economy having taken a dip amidst the COVID-19 pandemic.

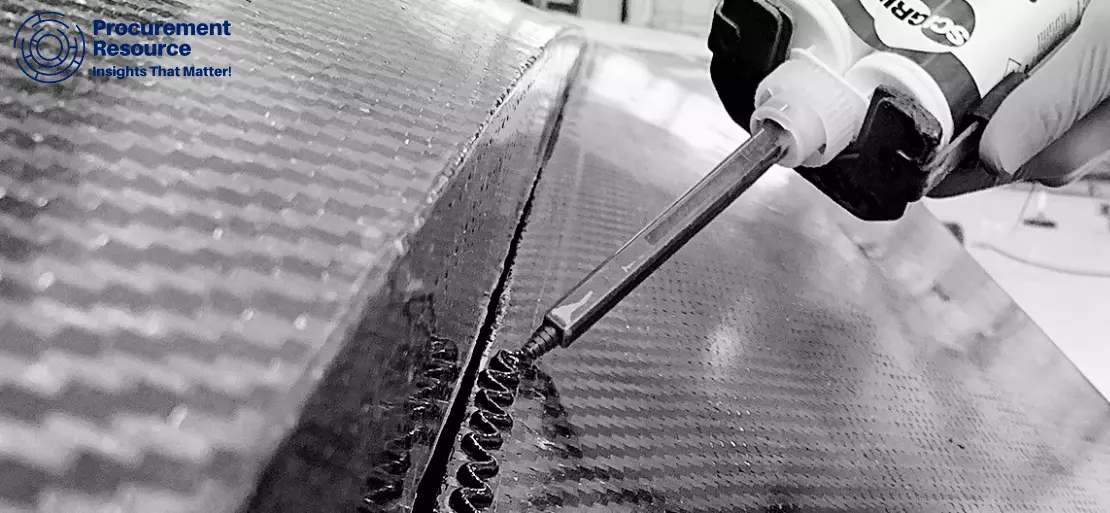

PMMA is a chain of an organic compound known as MMA (methyl methacrylate). It is a widely used compound in various industries. It is used to make products, such as automobile tail light lens, tableware, lighting plate, aquarium plate, contact lens, and others. Such an extensive usage of PMMA lead to a concern about its recycling process; thus, there was a need to innovate a new recycling process, which will make the PMMA recycling significantly easier.

However, PMMA is very difficult to recycle. Earlier, the only known method to recycle such a compound was twin-screw depolymerisation, which only synthesized the highest quality of PMMA, but, with the introduction of the MMAtwo project, the researchers now have a possible way to recycle this polymer more efficiently. Only recently, the scientists from the European Union have successfully commenced their first two days of pilot tests on June 16th, 2020, at Japan Steel Works with their partners from Heathland, Arkema, and Process Design Center. The leading scientists and research institutes have worked around the clock on this project and have established a depolymerisation unit, including a first in the field, pre-treatment plant.

The MMAtwo project was first introduced on October 1st, 2018, with an aim to develop a new and innovative way of recycling by the depolymerisation of PMMA and to allow the creation of the first commercial unit soon after the end of the project, i.e., by 2022. Previously, a process named ‘Twin-Screw Polymerisation’ was being used, but it could only depolymerise high-quality MMA and, thus, there was a need of a new recycling process, which will be able to depolymerise every kind of MMA and produce high-quality R-MMA (recycled-MMA) for industrial usage.

The main objectives of this project are:

- To build a new recycling value chain of PMMA in Europe, which includes the production waste and end of life waste, thus, covering the whole PMMA lifecycle.

- To use reactive recycling(depolymerisation), in order to produce high-grade PMMA and avoid downcycling.

- To innovate a lead-free technology which enables the recycling of lower quality waste.

This project was funded partially by the European Union, which gave EUR 6.6 million, and an additional EUR 2.9 million was invested by the other business partners. While the project aimed to build a recycling process, the European Union wanted to build a circular economy through the means of recycling the end life waste and industrial waste of PMMA, which explains as to why they want to keep continuing the project even during the pandemic.

The main motive behind this project was to provide an easier way to recycle PMMA, which will not only build an economy but also keep the environment safe, as R-MMA is considered to be environmentally-friendly. By making the recycling easier, it will also be beneficial to the industries because virgin MMA is volatile in nature.

The initial cost evaluation was also estimated to be 10-15% cheaper for recycled MMA as compared to virgin MMA. This is expected to make the R-MMA the preferred choice for a majority of the industries as it is cleaner and safer than virgin MMA, hence building a much larger industrial requirement. MMAtwo aims to secure the supply of commercial plant recycling units with at least 27000 tons feedstock PMMA scraps and end-of-life products, and, so far, they have managed to gather 12250 tonnes.

Through thorough evaluation before starting the project, these were the expected impacts:

- Expected to increase public awareness of PMMA recyclability and increase waste collection.

- Expected to recycle PMMA in Europe, including co-products fully.

- Expected to recycle waste into a high-end product.

- Expected to reduce energy consumption and CO2 emissions.

- Expected to build a positive economic business model.

- Expected to support recycling technology in order to impact people positively.

- Expected to gain knowledge on the subject.

The European Union believes that through this new and innovative recycling process, they will be able to make the recycling process of PMMA much easier for the industries. The new recycling process will also be more cost-efficient and will also produce high-quality MMA for industrial use.