Product

Polyvinyl Chloride (PVC) Price Trend and Forecast

Polyvinyl Chloride (PVC) Price Trend and Forecast

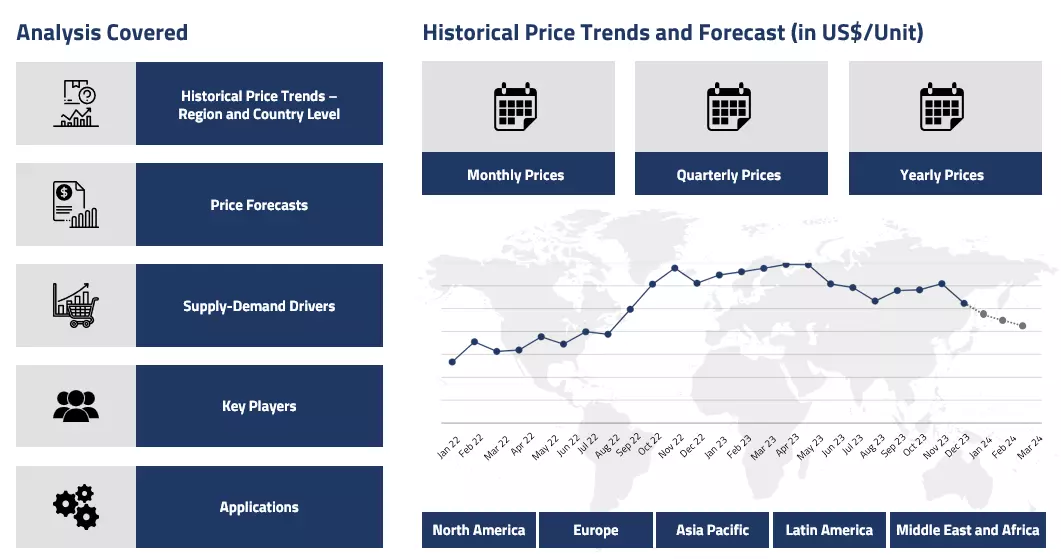

Polyvinyl Chloride Regional Price Overview

Get comprehensive insights into the Polyvinyl Chloride market, with a focused analysis of the Polyvinyl Chloride price trend across Asia, Europe, North America, Latin America, and the Middle East & Africa.

Polyvinyl Chloride (PVC) Price Trend for the First Half of 2025

Asia

In the first half of 2025, the PVC market in Asia faced a mostly bearish trend, especially in Q1, driven by weak export demand and a slow construction sector in China. Inventory levels remained high through January and February, with holiday disruptions like the Lunar New Year and Ramadan further reducing market activity. While production picked up in February, the lack of strong overseas demand and anti-dumping duties from India kept pressure on prices.

Polyvinyl Chloride (PVC) Price Chart

Please Login or Subscribe to Access the Polyvinyl Chloride (PVC) Price Chart Data

However, by late Q2, sentiment improved slightly due to a rise in trading volumes, steady domestic construction activity, and better outlooks in China’s property and manufacturing sectors. Despite weak costs from falling raw material prices, market optimism and active trading helped stabilize PVC pricing toward the end of H1.

Europe

PVC prices in Europe were mostly flat to weak in H1’25, influenced by sluggish demand and competitive import pressures. In Q1, feedstock prices dropped sharply, but suppliers were hesitant to lower PVC prices too far, attempting to protect margins. Demand, especially in the construction industry—particularly in countries like the Netherlands—remained soft, leading to high inventories.

Port congestion and Red Sea disruptions added logistical challenges. Moving into Q2, prices held steady but remained under pressure due to weak domestic consumption and an influx of low-cost imports from Asia. Even supply tightness from production cuts and force majeures couldn't offset the broader market weakness.

North America

The North American PVC market witnessed a declining trend in H1’25, particularly in Q1, with prices dropping sharply due to reduced feedstock costs and subdued construction activity. Harsh winter conditions and limited production did little to support prices, as demand stayed moderate. Export activity was weak, particularly to Latin America and Canada.

In Q2, the market found some balance as tariffs on US-China trade were postponed, boosting confidence. Producers began holding off on further discounts amid signs of a potential rebound, especially with improving margins in markets like Africa. Still, logistics constraints from increased Asian exports created upward cost pressure.

Analyst Insight

According to Procurement Resource, cautious optimism remains for H2’25, with some recovery expected as construction demand picks up and supply-demand balances improve globally.

Polyvinyl Chloride (PVC) Price Trend for Q4 of 2024

| Product | Category | Region | Price | Time Period |

| Polyvinyl Chloride (PVC) | Packaging | China | 754 USD/MT | October’24 |

| Polyvinyl Chloride (PVC) | Packaging | China | 688 USD/MT | December’24 |

| Polyvinyl Chloride (PVC) | Packaging | India | 1130 USD/MT | October’24 |

| Polyvinyl Chloride (PVC) | Packaging | India | 1129 USD/MT | December’24 |

Stay updated with the latest Polyvinyl Chloride (PVC) prices, historical data, and tailored regional analysis

Asia

In Q4 2024, PVC prices in Asia exhibited a mixed trend, initially rising before stabilizing due to supply-demand imbalances. Early in the quarter, prices gained support from increased construction sector activity in China, driven by government stimulus initiatives aimed at stabilizing the real estate market. Additionally, India’s imposition of anti-dumping duties on PVC imports from China and other regions strengthened domestic production margins, offering price support.

Monthly average EXW prices in the Indian market varied between 1130 USD/MT and 1129 USD/MT. In China, however, by mid-quarter, high inventory levels and continued robust production in China created downward pressure on prices. The monthly average prices for pipe grade PVC went from about 754 USD/MT in October’24 to 688 USD/MT in December’24.

Demand from downstream sectors such as infrastructure and manufacturing remained steady but lacked significant growth momentum. The latter half of the quarter saw prices stabilizing as winter-season slowdowns in construction tempered procurement activity. Despite these fluctuations, regulatory interventions and stable upstream costs prevented any steep declines. Looking ahead, PVC prices in Asia are expected to remain range-bound, influenced by domestic policies and global economic conditions.

Europe

The European PVC market in Q4 2024 experienced a generally stable to upward trend, supported by a combination of supply constraints and inflationary pressures. Early in the quarter, production challenges in key manufacturing facilities, including Belgium’s Vynova plant, led to tighter supplies and contributed to price resilience. Despite weaker overall demand from the construction sector, which faced ongoing economic challenges and high material costs, supply-side constraints kept prices firm.

Freight cost increases from Asian suppliers also played a role in maintaining price stability. In the UK, PVC prices remained steady throughout the quarter, supported by balanced domestic supply and stable demand from infrastructure projects. However, the German construction sector continued to contract, limiting broader market growth. By December, while European PVC prices saw minor fluctuations, steady ethylene costs and controlled production rates helped prevent significant declines.

North America

PVC prices in North America followed a declining trend in Q4 2024, influenced by weak demand and macroeconomic uncertainties. The construction sector, which constitutes the bulk of PVC consumption, exhibited mixed signals while home sales were stable in October, rising mortgage rates in November and December dampened new project activity. Additionally, subdued demand from the automotive sector, coupled with high inventory levels, pressured prices downward.

Seasonal slowdowns and cautious procurement strategies further exacerbated the bearish sentiment in the market. On the supply side, while production rates were adjusted to match lower demand, logistical challenges such as port congestion and rising imports continued to affect price stability. Despite these pressures, steady ethylene costs prevented more severe price drops. As the year ended, the market remained weak, with limited signs of immediate recovery.

Analyst Insight

According to Procurement Resource, Moving forward, market stability will depend on demand recovery in key sectors and potential changes in global trade dynamics.

Polyvinyl Chloride (PVC) Price Trend for Q3 of 2024

| Product | Category | Region | Price | Time Period |

| Polyvinyl Chloride (PVC) | Packaging | Europe | 1142 USD/MT | July'24 |

| Polyvinyl Chloride (PVC) | Packaging | Europe | 1152 USD/MT | August'24 |

Stay updated with the latest Polyvinyl Chloride (PVC) prices, historical data, and tailored regional analysis

Asia

The prices of polyvinyl chloride (PVC) exhibited a declining trend in the Chinese market during the third quarter of 2024, with occasional reverse fluctuations. Spot prices fell from approximately 766 USD/MT in July to around 735 USD/MT in September. Similarly, in the Indian PVC market the average prices went from about 1279 USD/MT in July’24 to around 1120 USD/MT in September of 2024. Low downstream procurement and ample supply contributed to the downward pressure on prices.

The production costs of PVC were primarily affected by fluctuations in raw material prices. Notably, calcium carbide prices significantly decreased due to the centralized maintenance activities of PVC plants and an increase in market supply. This decline in calcium carbide prices reduced PVC production costs but simultaneously compressed the profit margins of PVC companies. By late August, the declining cost of calcium carbide further reinforced the downward trajectory of PVC prices.

Europe

Unlike the trend observed in the Chinese market, PVC prices in the European market followed a rising trajectory in July. At the beginning of the quarter, prices increased gradually from approximately 1142 USD/MT (FD NWE) in July to around 1152 USD/MT (FD NWE) in August.

Moderate demand from the downstream construction sector, coupled with low inventory levels, contributed to this price increase. Supply constraints also benefitted manufacturers and traders, allowing them to maintain higher prices in the short term. Furthermore, factories were operating below full capacity, which restricted supply and supported the upward price movement. The rise in upstream ethylene prices added additional pressure, further driving up PVC prices.

North America

PVC prices in the North American market exhibited mixed trends during the said time period. Demand from the construction sector had weakened, along with the housing market, in particular, failing to support strong growth in the PVC market. This decline was primarily attributed to production disruptions caused by the hurricane season, coupled with rising feedstock prices.

In September, Hurricane Francine approached the coast, forcing several production companies to shut down their plants in Louisiana, which created a temporary supply crunch in the region. However, the overall demand outlook still remained underwhelming.

Analyst Insight

According to Procurement Resource, the prices of polyvinyl chloride (PVC) are expected to remain volatile depending on the prices of feedstock and downstream demand factors.

Polyvinyl Chloride Price Trend for Q2 of 2024

Asia

The prices of polyvinyl chloride fluctuated in a narrow range during the second quarter of 2024, but the momentum of the downstream industries was able to close this quarter on a positive note. In April, the strong demand and consequent increase in the pricing quotations from the manufacturing sector, supported by the peak season for plastic production and pre-holiday stocking, drove the market trend of polyvinyl chloride.

But this trend phased out as the decline in the sales figures of May and the cautious stance adopted by the consumer sector concerned the traders. However, as the quarter approached its end, overseas inquiries increased, and with that macroeconomic factor of the market also registered significant gains. Therefore, influenced by these market parameters, the traders were able to shift the monthly average of PVC prices from 767 USD/MT in April to 824 USD/MT in June.

Europe

The second quarter brought visible fluctuations in the polyvinyl chloride market as, after a weak phase initially, the market registered slight gains towards the end. During the early phase of the second quarter, the market activities were challenged by the falling cost of production and declining prices of key feedstocks such as ethylene dichloride, vinyl chloride monomer, and upstream crude oil.

The European buyers thus actively offered price concessions in order to keep the prices of the commodity above par. This trend was also fueled by the increasing pricing of shipping containers from Asia as Western retailers raised their import values in anticipation of the upcoming demand season and the imposition of heavy tariffs on Chinese imports ahead of the US election season. However, from June, the concerns of the traders eased out as the prices began to move upward, and they were able to close the quarter with slight gains.

North America

In the US, polyvinyl chloride producers maintained strong pricing throughout Q2 2024, supported by escalating domestic demand and high domestic prices. The strong domestic market dynamics led to price stability or even increases in regions where supply was tight. The high domestic prices in the US were primarily driven by sustained demand in the downstream construction industry and other sectors, which countered the downward pressure from decreasing raw material and energy costs. Additionally, US-origin polyvinyl chloride gained significant interest in the European and UK markets during this period, as European buyers turned to US suppliers to mitigate the impact of rising shipping costs and supply chain disruptions from Asia.

Analyst Insight

According to Procurement Resource, the price trend of Polyvinyl Chloride is estimated to escalate further as the seasonal demand for polyvinyl chloride downstream commodities is expected to drive the momentum of the market.

Polyvinyl Chloride (PVC) Price Trend for Q1 of 2024

| Product | Category | Region | Price | Time Period |

| Polyvinyl Chloride (PVC) | Packaging | USA | 735 USD/MT | January 2024 |

| Polyvinyl Chloride (PVC) | Packaging | USA | 755 USD/MT | March 2024 |

Stay updated with the latest Polyvinyl Chloride (PVC) prices, historical data, and tailored regional analysis

Asia

Polyvinyl Chloride (PVC) prices were observed to be wavering throughout the said period of the first quarter of the year 2024. The price progression of the said period was very confined and seemed tugged between various driving factors. Subdued and humble demands from the very beginning as the inventories were largely optimum, which exerted a little downward pressure on the market performance.

The growth in the upstream costs because of a very significant incline in the crude oil and energy prices pushed the market rates forward for PVC in the regional Asian markets. Despite a very restrained run, the Indian PVC market’s performance was better than the Chinese market during the given span.

In the Chinese markets, the PVC saw the monthly average prices (for pipe grade PVC) going from about 782 USD/MT in January’24 to around 780 USD/MT in March’24. On the other hand, In the Indian markets, the monthly average prices went from about 1058 USD/MT (EWX) to around 1086 USD/MT through the same span.

Europe

In the European PVC market, the market sentiments were mixed as the price trend showed significant variations throughout the given period. The first half of the first quarter was more inclined compared to the second quarter.

Prices went uphill first as the rise in production cost with the increased fuel and energy prices after OPEC+ announced a price hike observing around a 4% rise in the monthly average prices from January to February. However, as the inventories kept bulking up and exceeded the demands by large margins, the prices came down in a similar manner and fell by about 7% in the next couple of months. The monthly average prices (Europe, FD NEW, Suspension Grade) went from about 1232 USD/MT in January ’24 to around 1180 USD/MT in March’24.

North America

Driven by the hike in raw material prices and energy costs, the PVC market progression in the USA was pretty positive during the first quarter of 2024. Market demands were humble yet steady and well supported the pricing dynamics for the said duration. In the American market, the monthly average prices went from about 735 USD/MT (USA, FOB Texas, Suspension Grade) in January’24 to around 755 USD/MT in March of 2024. This imparted an approximate growth of about 2% in the American polyvinyl chloride market.

Analyst Insight

According to Procurement Resource, given the current supply and demand dynamic and the macroeconomic scenarios, the price projections for Polyvinyl Chloride are optimistic for the coming months.

Polyvinyl Chloride (PVC) Price Trend for Q4 of 2023

| Product | Category | Region | Price | Time Period |

| Polyvinyl Chloride (PVC) | Packaging | USA | 715 USD/MT | Jan-24 |

| Polyvinyl Chloride (PVC) | Packaging | USA | 745 USD/MT | Dec-2023 |

| Polyvinyl Chloride (PVC) | Packaging | USA | 750 USD/MT | October’23 |

Stay updated with the latest Polyvinyl Chloride (PVC) prices, historical data, and tailored regional analysis

Asia

The Asian Polyvinyl Chloride market registered consistent fluctuations during the final quarter of the year 2023. Since PVC is produced with the polymerization of vinyl chloride monomers, the market trends are affected by the price patterns of vinyl chloride monomeric units.

The Chinese Polyvinyl Chloride market wavered more on the lower side of the price curve as the average monthly spot prices for pipe grade PVC were observed to be standing at around 813 USD/MT in October’23 and then marginally slid to about 798 USD/MT in December’23. However, the Indian Polyvinyl Chloride market ascended by about 9% during the same time. In the Indian PVC market, the prices averaged around 1000 USD/MT (EXW, India) in October’23 and averaged at around 1090 USD/MT in December’23. Overall, very mixed market trends were observed for PVC during the said period.

Europe

The European PVC market was more influenced by the Chinese PVC market as the prices here, too, were observed to be declining during the last three months of 2023. The monthly average prices were observed to be declining from around 1322 USD/MT (FD, NEW, Suspension Grade) in October’23 to about 1215 USD/MT in December’23. This resulted in a depreciation of around 8% in the European PVC market trends.

North America

The PVC prices varied within very closed limits in the North American markets during the final quarter of the year 2023. In the US market, prices first fell by about 2% in the first half of the quarter and then stabilized by 2% in the latter half. As a result, the prices marginally slid by the end of the quarter.

The monthly average shifted from around 750 USD/MT (FOB, Suspension Grade, Texas) in October’23 to about 745 USD/MT in December’23. As the market is still recovering, the cautious wait-and-see approach of buyers is likely to affect the pricing, causing them to average around 715 USD/MT in January’24.

Analyst Insight

According to Procurement Resource, similar fluctuations are anticipated in the Polyvinyl Chloride markets going forward as well. Prices are expected to continue to vary regionally as per regional market demands.

Polyvinyl Chloride (PVC) Price Trend for Q3 of 2023

Asia

The Polyvinyl Chloride market observed an upward surge throughout the given period of Q3’23. Regular and astonishing demands from the downstream plastics and construction industries guided these favorable market sentiments. In the Chinese PVC market, the quarterly inclination of about 10% was experienced as the monthly average spot prices (for pipe grade PVC) inclined from about 776 USD/MT in July to around 857 USD/MT in September 2023.

The Indian PVC market was relatively more stable; however, a quarterly rise of around 2% was noticed in the Indian polyvinyl chloride market as well since the average monthly prices shifted from about 1035 USD/MT (EXW) in July’23 to around 1064 USD/MT in September of 2023. Overall, very positive market sentiments were observed in the polyvinyl chloride market as the supply and demand maintained their momentum and escalated throughout the given period.

Europe

The European polyvinyl chloride market trend were more mixed. As the first half of the quarter saw rising prices, however, the second half was more negatively tilted. The market demands guided these price patterns, but the oversupplied inventories became dominant in the latter half.

The monthly average prices rose marginally by around 1% from July to August but dipped by around 5% in the next set of months. The polyvinyl chloride prices averaged around 1450 UD/MT (FD NEW, Suspension grade) in July and stood at around 1387 USD/MT in September. Overall, varying price trend were observed.

North America

The American polyvinyl chloride market remained affected by the difficult economic situation in the region. The prices were confined to very narrow limits since not much market activity was happening around polyvinyl chloride. A marginal quarterly slip of around 1% was seen at the end. The polyvinyl chloride prices averaged around 790 USD/MT (FOB Texas, suspension grade) throughout the said quarter.

Analyst Insight

According to Procurement Resource, the Polyvinyl Chloride prices are likely to continue varying going forward. The regional market demands and supply dynamics will guide the polyvinyl chloride price trend.

Polyvinyl Chloride (PVC) Price Trend for the First Half of 2023

Asia

Polyvinyl Chloride (PVC) prices had a downward trend in the first half of 2023. After an almost stagnant start, prices declined from February to the end of June’23. Bearish demands remained the factor behind these sluggish price trend. The Chinese market recorded its lowest Producer Price Index (PPI) since 2015, with the steepest decline of 5.5% from the previous year.

The lowering demand from the packaging and construction industries aided the negative movement in PVC prices. The spot prices of PVC (Pipe grade) declined from about 908 USD/MT in January to around 776 USD/MT in June’23, recording a decline of approximately 14% in the Chinese domestic market.

Europe

The European PVC market recorded a bearish sentiment in the first half of 2023. Since the onset of the Russia-Ukraine war in 2022, inflation clouded the European markets as energy prices soared. Germany underwent an economic recession in May 2023 as a result of these inflated living costs. This seriously impacted the downstream housing and construction industries. European PVC prices registered a decline of around 18% in the first quarter. This southward movement continued well in the second quarter owing to the bearish market fundamentals.

North America

The US domestic market mimicked the same global outlook as consistently falling end-consumer demands continued to push the PVC prices. The soaring inflation and supply-chains disruptions continued to plague the downstream demand from packaging industries. Further, the arrival of cheap Chinese products caused PVC prices to fall.

Analyst Insight

According to Procurement Resource, PVC prices are expected to fluctuate and eventually get plateaued. The supply-demand dynamics will strive for equilibrium, given that all the other factors remain consistent. Market demand is expected to remain the major driving factor for PVC price trend.

Polyvinyl Chloride Price Trend for the Second Half of 2022

Asia Pacific

The prices of polyvinyl chloride saw a sluggish trend in the Asian-Pacific region throughout the third quarter. The demand saw a negative surge due to the ripple effects of the COVID-19 pandemic as consumer confidence declined in the market. The weak market affected the freight charges, and bad weather conditions contributed to the downhill movement of the market. The market uncertainties and low consumer confidence continued to lead the PVC market in the negative zone in the fourth quarter also. The South Korean market slumped the greatest as the decline in overseas demand and abundant supply shadowed the prices in the region.

Europe

The European market mirrored the trend seen in the Asian-Pacific market. The downward growth of prices was supported by the decline in domestic demand from the construction sector and a rise in energy production costs due to the ongoing Russia-Ukraine conflict.

The region also saw increasing inflation rates that further demoralized the buyers and, as a result, the manufacturers had to reduce their profit margins. The fourth quarter also followed in the footsteps of the previous one, and the negative growth in the prices continued to occur. The producers of this polymer continued to suffer due to the high uncertainties, rise in energy production costs, and inflation rates in the region.

North America

The North American market tumbled throughout the third quarter as the weak demand from end-user industries factored in the decline in the prices of the commodity. Another reason for this sluggish behaviour in the third quarter is the rise in inventories and high energy production costs. The construction sector, however, affected the market the most as the mortgage rate continued to soar, and the buyers hesitated to participate in the market. Further, the low demand and rise in inventories fueled the negative incline in the prices throughout the fourth quarter.

Analyst Insight

The prices of Polyvinyl chloride are likely to decrease during the coming month given a decline in demand from the end-user industries amid increasing cost of production and high inflation rates. The rise in inventories and low house-building activities will continue to pitch in the negative trend being followed by the prices of the commodity.

Polyvinyl Chloride (PVC) Price Trend for Second Quarter of 2022

Asia

In the Chinese market, sluggish demand for Poly Vinyl Chloride amid weak upstream feedstock Calcium Carbide led to decreasing price trend for PVC. A rise in Covid-19 cases in China led to congestion of ports which further dropped transportation activities. The uncertainty of the pandemic affected offtakes from the downstream industries. Producers reduced production rates due to continuous lockdowns and rigid quarantine protocols.

Additionally, the price of feedstock calcium carbide decreased at the beginning of April in China as the number of Covid 19 cases climbed again which reduced the demand amid abundant stocks in the domestic market of China. Most market distributors were forced to sell their stocks in the regional market due to logistical bottlenecks like unavailability of rail, car and truck services. Towards the end of May, price of PVC5 type was somewhere around 8600 RMB/MT.

Europe

Poly Vinyl Chloride market observed a surge in prices in Europe, supported by the high demand from the end-use downstream segments. The ongoing war between Ukraine and Russia led to soaring high values of energy which pushed raw material costs to rise in the European markets. Demand from downstream automotive segments for PVC also remained high in the region while supply remained limited and profits were squeezed.

PVC prices in July had dropped by 50-80 EUR/MT in Europe as a result of increased availability and high demand from downstream sectors.

North America

In North America, PVC prices surged at the end of April 2022 amid supply disruption as ports were congested at various container terminals, leading to a shortage of feedstock ethylene. Rising tensions between Ukraine and Russia eventually congested ports in the USA.

Analyst Insight

According to Procurement Resource, the prices for polyvinyl chloride are expected to devastate in the second half of the year. The crippling pathway for PVC prices could be projected on the back of the Russia-Ukraine war globally, higher feedstock prices, and lesser consumer demand amidst covid-19 restrictions in China.

Polyvinyl Chloride (PVC) Price Trend for First Quarter of 2022

Asia

The average domestic spot price of PVC5 type was 8,880 RMB/MT on March 29, down 0.56% from the previous trading day but up 3% year on year. The disc was on the strong side, and the spot market's environment was heating up because of the upward trend in futures.

The investors' offer grew, and the market's attention shifted upward. Following the price increase, downstream enquiries were usual, high-priced transactions were normal, and actual deals were mostly negotiated. Towards the end of March, the price of PVC was around 8,900-9,300 RMB/MT.

North America

The availability of raw materials for PVC was anticipated to decrease in Q1 due to a slew of turnarounds planned at chlor-alkali facilities. Players' margins are projected to narrow as they will be unable to pass on the cost pressure to customers if the demand environment continues unchanged. On the other hand, because chlorine availability is predicted to drop, a scarcity of PVC could occur in late Q1, putting the operating rate of numerous PVC plants at risk.

Polyvinyl Chloride (PVC) Price Trend for Fourth Quarter of 2021

Asia

With supply exceeding demand, Pipe Grade prices in China fell to a record low of 1345 USD/MT FOB Shanghai in December, while Calendaring Grade prices remained stable at 1740 USD/MT.

The market sentiment first increased in October before seeing a sharp decline by the end of December. PVC prices continued to rise in October, owing to strong demand from the packaging and construction sectors during the peak Christmas season.

After reaching a record high of 161.84 INR/kg on October 14, 2021, Indian manufacturers lowered their PVC resin prices weekly in response to global market conditions. PVC prices in the GCC (Gulf Cooperation Council) area of the Middle East fell by more than 20% to trade at around 1600-1650 USD/MT, down from a record high of 2050-2120 USD/MT in early November 2021.

Europe

In December, Suspension Grade PVC prices in Europe hit 2050 USD/MT FD Germany. Europe was experiencing a severe scarcity of Vinyl Chloride Monomer (VCM), forcing a major PVC producer, Vynova, to operate both of its plants in Belgium at less than 50% capacity.

Additionally, Vinnolit's force majeure at its caustic soda facility resulted in a decline in the availability of its feedstock chlorine in the first part of the quarter. Although feedstock supplies began to stabilize in late November, PVC prices continued to rise steadily as a result of lower output and high energy prices.

North America

In December, supply outstripped demand, resulting in a month-long decline in the prices. In the final week of December, the prices fell to 1680 USD/MT FOB Texas for Suspension Grade. Due to the interdependence of the Chlor-Alkali and PVC markets, constrained production of caustic soda due to low operating rates as a result of the Ida hurricane in mid-Q2 2021 continued to strain supplies in the quarter ending December. After reaching an all-time high in November, PVC prices subsequently fell owing to the off-season’s lack of demand.

Polyvinyl Chloride (PVC) Price Trend for First, Second and Third Quarters of 2021

Asia

In April, the Asian market saw robust demand from the downstream construction industry, which then dropped in May. During April, manufacturers in China were effortlessly shipping PVC to the Indian market at rather high costs. The sharp increase of pandemic cases in India lowered its demand in the related building market. As a result, PVC prices in the Indian market fell in the second half of the quarter reaching 1617 USD/MT in the final week of June.

Further, PVC prices increased rapidly during the second quarter, owing to strong demand from the local market and inadequate cargo supply. Increased shipping container pricing and increased freight costs across Southeast Asia aided in the quarter's price increase trend.

Additionally, the winter storm that swept across the US Gulf area interrupted global supplies and harmed Asia's commercial activities. Additionally, the Chinese market's bullish demand for the polymer helped the price in other APAC nations, such as India. The CFR price in India increased by approximately 30% in March and ended at 1615.97 USD/MT.

PVC prices increased significantly in the Asia Pacific area during the third quarter of 2021. The pricing trend continued to rise in the face of an active polymer market and a worldwide supply shortfall. In India, pricing increased significantly, with CFR ICD Delhi prices increasing from 1429 USD /MT to 1680 USD/MT in Q3 2021.

Europe

Europe saw a significant increase in the price of PVC, owing to a strong demand pattern and major feedstock and material shortages. During this period, shipments from Europe increased overall in Q1 2021, owing to decreasing manufacturing along the US Gulf coast. Due to rising freight costs and a lack of shipping containers, prices increased to over 113 USD/MT in several CIS nations. Domestic output remained constrained across the area owing to planned and unanticipated plant shutdowns.

In Q3 2021, the general market prognosis for the polymer in Europe indicated an increasing trend. The pricing chart demonstrated an increased trend in the market during September, owing to a severe lack of raw materials, which resulted in an increase in regional prices. Shipment costs were stable as congestion in ports remained a major concern. Additionally, logistical concerns such as container shortages and rising freight prices added value to all imported goods in Europe during this quarter.

North America

North America’s production was hampered by a severe freezing storm across the gulf, forcing the overall output to its lowest level in Q1 2021. Due to the disruption caused by the winter storm, the supply of feedstock materials such as monomer vinyl chloride was decreased, and strong demand from both the local and foreign markets pushed prices upward. As a result, the region's average price increased by 16.83% and settled at 1717.5 USD/MT in March.

After experiencing record increases through the end of April, PVC prices began to normalize in May as supply activity in the United States improved. The resurgence of the North American market following a successful immunization campaign increased demand for PVC in the domestic building industry.

Since late August, when Hurricane Ida made landfall on 29th August, key manufacturing factories from Baton Rouge to New Orleans along the Mississippi river, which accounted for over half of US PVC output, had been forced to shut down. Since the first week of September, PVC prices had been soaring, reaching an all-time high of 1960 USD/MT FOB Louisiana and 1940 USD/MT FOB Texas in September. However, prices moderated in the last week of September as output increased as a result of plant restarts in Texas and Louisiana.

Polyvinyl Chloride (PVC) Price Trend for the Year 2020

Asia

Asia witnessed supply shortage as producers dumped cargoes, resulting in smaller product inventories. The supply shortage was exacerbated further when a major manufacturer in Northeast Asia went into maintenance mode. As a result of several nations' success in containing the spread of contagion, market activity gradually rose towards the end of the quarter, owing to the region's continued relaxation of restriction measures.

Traders reported increasing purchases as customers expressed optimism about future demand resuscitation following the restart of production in the majority of downstream businesses. With multiple scheduled plant outages planned for later in the year, that the demand-supply imbalance was anticipated to worsen.

Levitating at the highest in at least five years, the market price had an increase of 60% from its level of 88.55 INR/kg a year ago and more than 125% climb from the worldwide shutdown era when the plastic raw material was quoted at 62.99 INR/kg in May 2020.

Europe

Since the rise began in early June 2020, spot K67(PVC Resin Virgin) prices in Italy and Northwest Europe increased by around 900-950 EUR/MT, or by 135%. In Europe, recent PVC offers for September suggested moderate rises despite the somewhat lower ethylene settlement.

The bullish trend began its sixteenth month, with supply-demand dynamics continuing to be critical in determining the market's tone, increasing the prices. Several regional producers increased their offerings by up to 30-50 EUR/MT, while others increased them by less than 10-20 EUR/MT.

North America

In 2020, Egypt was the fourth-largest export destination for US PVC. The export prices were 1,450 USD/MT in December 2020 which were expected to rise to as high as 2100 USD/MT. Since August 2020, when the first of two hurricanes struck Louisiana within six weeks of each other, the export supply availability was constrained, exacerbated by widespread shutdowns in response to a deep freeze that hit the US Gulf Coast in mid-February 2021 and Hurricane Ida's landfall in Louisiana.

Procurement Resource provides latest prices of PVC. Each price database is tied to a user-friendly graphing tool dating back to 2014, which provides a range of functionalities: configuration of price series over user defined time period; comparison of product movements across countries; customisation of price currencies and unit; extraction of price data as excel files to be used offline.

About Polyvinyl Chloride (PVC)

PVC or Poly Vinyl Chloride is a thermoplastic polymer that is also a synthetic resin. Owing to its versatile nature, PVC has become one of the most widely used polymers in the world. It is known to be chemically resistant to several materials such as acids, salts and fats. It is produced by a process called polymerisation. It is used in plethora of places like water pipes, electronics, packaging, etc. PVC is the third-most widely manufactured synthetic plastic polymer worldwide.

Polyvinyl Chloride (PVC) Product Details

| Report Features | Details |

| Product Name | Polyvinyl Chloride (PVC) |

| Chemical Formula | (C2H3Cl)n |

| Industrial Uses | Plastic products, Construction material, Electronics and automobile parts, Packaging, Water pipes |

| Synonyms | 9002-86-2, poly(1-chloroethylene), Polychloroethylene |

| Supplier Database | Shin-Etsu Chemical Co., Ltd, Formosa Plastics Corporation, Occidental Petroleum Corporation, LG Chem Ltd., Reliance Industries Limited |

| Region/Countries Covered | Asia Pacific: China, India, Indonesia, Pakistan, Bangladesh, Japan, Philippines, Vietnam, Iran, Thailand, South Korea, Iraq, Saudi Arabia, Malaysia, Nepal, Taiwan, Sri Lanka, UAE, Israel, Hongkong, Singapore, Oman, Kuwait, Qatar, Australia, and New Zealand Europe: Germany, France, United Kingdom, Italy, Spain, Russia, Turkey, Netherlands, Poland, Sweden, Belgium, Austria, Ireland Switzerland, Norway, Denmark, Romania, Finland, Czech Republic, Portugal and Greece North America: United States and Canada Latin America: Brazil, Mexico, Argentina, Columbia, Chile, Ecuador, and Peru Africa: South Africa, Nigeria, Egypt, Algeria, Morocco |

| Currency | US$ (Data can also be provided in local currency) |

| Supplier Database Availability | Yes |

| Customization Scope | The report can be customized as per the requirements of the customer |

| Post-Sale Analyst Support | 360-degree analyst support after report delivery |

Note: Our supplier search experts can assist your procurement teams in compiling and validating a list of suppliers indicating they have products, services, and capabilities that meet your company's needs.

Polyvinyl Chloride (PVC) Production Process

- Production of PVC via Polymerisation of Vinyl Chloride Monomer (VCM)

The initial step of polymerisation includes liquefying and putting pressure on raw VCM material. After that, it is processed in a polymerisation reactor, where it meets water and suspending agents. Then, it is fed into another reactor, where PVC is manufactured at 40 – 60°C. PVC obtained upon the completion of process is suspended in water as particles of 50~200 μm diameter and that too in slurry form.

Methodology

The displayed pricing data is derived through weighted average purchase price, including contract and spot transactions at the specified locations unless otherwise stated. The information provided comes from the compilation and processing of commercial data officially reported for each nation (i.e. government agencies, external trade bodies, and industry publications).

Assistance from Experts

Procurement Resource is a one-stop solution for businesses aiming at the best industry insights and market evaluation in the arena of procurement. Our team of market leaders covers all the facets of procurement strategies with its holistic industry reports, extensive production cost and pre-feasibility insights, and price trends dynamics impacting the cost trajectories of the plethora of products encompassing various industries. With the best analysis of the market trends and comprehensive consulting in light of the best strategic footstep, Procurement Resource got all that it takes.

Client's Satisfaction

Procurement Resource has made a mark for itself in terms of its rigorous assistance to its clientele. Our experienced panel of experts leave no stone unturned in ensuring the expertise at every step of our clients' strategic procurement journey. Our prompt assistance, prudential analysis, and pragmatic tactics considering the best procurement move for industries are all that sets us apart. We at Procurement Resource value our clients, which our clients vouch for.

Assured Quality

Expertise, judiciousness, and expedience are the crucial aspects of our modus operandi at Procurement Resource. Quality is non-negotiable, and we don't compromise on that. Our best-in-class solutions, elaborative consulting substantiated by exhaustive evaluation, and fool-proof reports have led us to come this far, making us the ‘numero uno' in the domain of procurement. Be it exclusive qualitative research or assiduous quantitative research methodologies, our high quality of work is what our clients swear by.

Related News

Table Of Contents

Our Clients

Get in Touch With Us

UNITED STATES

Phone:+1 307 363 1045

INDIA

Phone: +91 8850629517

UNITED KINGDOM

Phone: +44 7537 171117

Email: sales@procurementresource.com

.webp)