Product

PTA (Purified Terephthalic Acid) Price Trend and Forecast

PTA (Purified Terephthalic Acid) Price Trend and Forecast

Purified Terephthalic Acid (PTA) Regional Price Overview

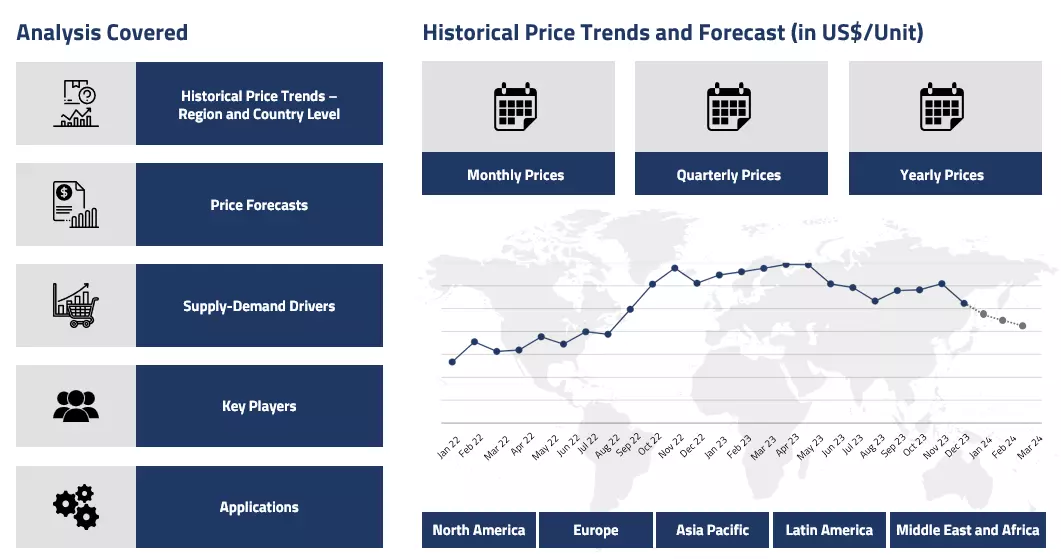

Get the latest insights on price movement and trend analysis of PTA (Purified Terephthalic Acid) in different regions across the world (Asia, Europe, North America, Latin America, and the Middle East & Africa).

Purified Terephthalic Acid (PTA) Price Trend for the Q4 of 2024

Asia

In Q4’24, PTA prices in Asia exhibited an upward trend, primarily driven by the strong performance of its key feedstock, xylene. Chinese markets led the regional price surge, particularly in December, when supply tightness in xylene created upward pressure on PTA production costs.

Purified Terephthalic Acid (PTA) Price Chart

Please Login or Subscribe to Access the Purified Terephthalic Acid (PTA) Price Chart Data

The market was further supported by steady downstream polyester demand, especially from the textile sector preparing for the spring season. Southeast Asian producers operated at reduced rates during October and November due to maintenance schedules, which helped maintain the supply-demand balance. Indian markets showed mixed sentiment, with demand remaining moderate despite the festival season.

Europe

European PTA markets witnessed volatility throughout Q4’24. The market initially struggled with high energy costs and reduced operating rates at several facilities. However, by mid-November, the situation improved as energy prices stabilized. Downstream polyester demand remained sluggish, with many converters operating at lower rates due to economic uncertainties. The market saw some support from reduced imports from Asia, as Asian producers focused on their domestic markets. December brought modest improvements in demand as textile manufacturers began preparing for the spring season.

North America

The North American PTA market showed resilience in Q4’24. The region experienced improved margins compared to other global markets, benefiting from relatively stable feedstock costs. Producer inventory levels remained balanced, though operating rates were adjusted downward in December due to seasonal factors. Demand from the packaging sector remained steady, while textile and fibre applications showed some weakness. The Mexican market saw increased activity, particularly in the bottle-grade PET segment.

Analyst Insight

According to Procurement Resource, Purified Terephthalic Acid (PTA) markets are expected to maintain their strength, supported by anticipated improvements in downstream demand and continued tightness in feedstock markets. The trajectory of crude oil prices and potential geopolitical developments in the Middle East would likely play crucial roles in determining market direction.

Purified Terephthalic Acid (PTA) Price Trend for the Q3 of 2024

Asia

The Asian market witnessed a consistent decline in prices during Q3’24. The key feedstock xylene tracked the downward movement of crude oil, leading to a significant reduction in production costs for regional PTA manufacturers. Chinese PTA producers adjusted their operating rates downward as inventories built up due to sluggish downstream demand, particularly from the polyester sector.

Buyers in the region adopted a wait-and-see approach, making minimal purchases as they anticipated further price drops. Towards the latter half of the quarter, PTA producers struggled to maintain their margins despite the lower input costs, as end-use industries showed limited buying enthusiasm.

Europe

The European domestic market followed in the footsteps of its Asian counterpart. The cascade effect of declining crude oil and naphtha values put significant pressure on regional PTA price levels. The slowdown in the construction and packaging sectors, key end-use industries for PTA, impacted the overall demand. Producers faced mounting pressure to adjust prices downward despite their efforts to protect margins. Port-related logistics challenges added complexity to material movements, though abundant product availability offset any potential supply concerns.

North America

The US purified terephthalic acid (PTA) sector witnessed a consistent decline in prices during the said quarter. Falling feedstock costs, driven by the weaker crude oil market, directly impacted the PTA market. Regional producers managed their output rates carefully as warehouse stocks remained comfortable. Downstream industries, particularly the textile and packaging sectors, showed selective buying patterns. The quarter closed with continued bearish sentiment as ample supply weighed on the demand, leading to sustained price pressure.

Analyst Insight

According to Procurement Resource, the prices of Purified Terephthalic Acid (PTA) are expected to remain volatile in the coming quarter given the current market fundamentals and the global economy.

Purified Terephthalic Acid (PTA) Price Trend for the Q2 of 2024

| Product | Category | Region | Price | Time Period |

| Purified Terephthalic Acid (PTA) | Packaging | China | 825 USD/MT to 823 USD/MT | Q2, 2024 |

Stay updated with the latest Purified Terephthalic Acid (PTA) prices, historical data, and tailored regional analysis

Asia

In Q2 2024, the Chinese purified terephthalic acid market experienced a notable downtrend due to an oversupply situation that pushed prices down significantly, particularly in early May, while the monthly average of the prices remained more or less stagnant as it shifted from 825 USD/MT to 823 USD/MT. The producers faced challenges in selling their products despite efforts to cut production and discounts on bulk purchases.

The market was even then pressurized with high inventory levels, and scheduled maintenance turnarounds and reduced import bids were insufficient to balance the excess supply. This bleak trend, escalated by a shift in downstream priorities towards essential commodities, led to reduced purified terephthalic acid purchases for non-essential applications.

The cautious purchasing behavior among market participants further strained the market momentum of the commodity. Additionally, a drop in spot ethylene prices and declining upstream crude oil futures undermined market confidence, deterring larger purchase commitments. However, the market reported a slight rebound in June with the onset of the peak season for the food and beverages packaging sector, as beverage plants ramp up bottled water distribution.

Europe

In the European region, purified terephthalic acid prices remained stable, particularly in Germany, primarily supported by the stagnancy in the cost of feedstock para-xylene. This stability was also influenced by the consistent demand from downstream packaging industries and a reduction in market activities by players, which contributed to the equilibrium.

The downstream PET resin market in Europe experienced steady improvement, with producers and buyers maintaining minimal stock levels. This created a potential for traders to raise their pricing quotations as the weather improved, although, for the time being, the market enjoyed uninterrupted supply and normal demand, ensuring stable prices. The equilibrium in the European purified terephthalic acid market was further supported by the diversion of end-user players towards domestic produce amid the limited influx from the Asian countries.

North America

In the North American region, purified terephthalic acid prices showed a mixed trend during the second quarter of 2024. The initial price surge was influenced by the increase in crude oil prices, limiting the production volumes amid moderate demand for the commodity. This upward movement was supported by a general trend of rising demand, although the physical demand was not exceedingly strong. However, as the quarter approached its termination, the trend stabilized under the ill influence of the economic downturn that caused an oversupply of naphtha and a subsequent drop in its prices. Also, the loss of export volumes due to rising freight charges and extension of lead times depreciated the interest of overseas players and exerted a negative influence on the pricing patterns of purified terephthalic acid.

Analyst Insight

According to Procurement Resource, the price trend of Purified Terephthalic Acid (PTA) is expected to oscillate amid the changing global trade dynamics and rising uncertainties in both its feedstock and end-user industries.

PTA (Purified Terephthalic Acid) Price Trend for the Q1 of 2024

Asia

In China, the domestic purified terephthalic acid market exhibited a fluctuating upward trend as the drivers of the market presented an uneven scenario during the first quarter of 2024. The market sentiments in the quarter's later phase were supported by positive factors on both the production and demand sides. The upstream ethylene glycol prices surged due to increased equipment maintenance and reduced supply.

Additionally, crude oil price fluctuations provided further support to the purified terephthalic acid price trend. Meanwhile, the operating rates of purified terephthalic acid factories decreased as the market entered the maintenance season, leading to a narrowing of the supply side. On the demand front, the downstream packaging factories experienced accelerated inventory consumption, prompting traders to initiate restocking activities.

Europe

The purified terephthalic acid prices in the European market saw a consistent upward trend, with Germany registering a significant uptick in downstream activities during the first quarter of 2024. This surge was further attributed to elevated feedstock prices and disruptions in the supply chain. Despite lackluster demand in the early phase of the quarter, the traders and manufacturers maintained their pricing of purified terephthalic acid, which further accelerated in the later phase of the quarter.

Additionally, the farmer protests across European nations against government green policies such as nitrogen emission curbs and pesticide bans intensified the constriction of already tinted supply chains and disrupted the flow of purified terephthalic acid to major countries of Europe. Additionally, high production costs and intensified competition from imports further contributed to the turmoil in the logistics department, which was already under the pressure of changing maritime routes and rising freight charges for European exports.

North America

The United States experienced significant price hikes in purified terephthalic acid due to disruptions in global ocean freight, primarily caused by events such as rebel attacks in the Red Sea and disturbances in traffic through the Suez Canal. These disruptions led companies to divert shipping routes, resulting in delays and a reduction in shipping container availability. Similarly, the European and Asian markets are grappling with shortages and rising freight rates.

Additionally, issues in the Panama Canal due to low water levels from a local drought have further complicated logistics. The US, heavily reliant on purified terephthalic acid imports and rising challenges in its domestic supply and pricing due to these logistical issues, further favored an uptick in the pricing patterns of purified terephthalic acid during Q1 of 2024.

Analyst Insight

According to Procurement Resource, the price trend of Purified Terephthalic Acid is expected to be driven by the rising demand from the downstream industries and the surging cost of oceanic transport routes.

Purified Terephthalic Acid (PTA) Price Trend for the October - December of 2023

| Product | Category | Region | Price | Time Period |

| Purified Terephthalic Acid (PTA) | Packaging | USA | 1479 USD/MT | December 2023 |

| Purified Terephthalic Acid (PTA) | Packaging | Europe | 1175 USD/MT | December 2023 |

| Purified Terephthalic Acid (PTA) | Packaging | China | 822 USD/MT | October 2023 |

| Purified Terephthalic Acid (PTA) | Packaging | China | 808 USD/MT | December 2023 |

Stay updated with the latest Purified Terephthalic Acid (PTA) prices, historical data, and tailored regional analysis

Asia

The price trend for purified terephthalic acid wavered at the lower end of the price curve during the fourth quarter of the year 2023. The Chinese market experienced a marginal depreciation during this time as the monthly average prices for purified terephthalic acid went from about 822 USD/MT in October to around 808 USD/MT in December’23.

The most extensive usability of purified terephthalic acid comes from the PET plastic industry, and because of the regular demands from the downstream polyester and PET industries, the purified terephthalic acid price trend remained consolidated within close ranges. Overall, mild fluctuations were witnessed in the purified terephthalic acid market during the said period.

Europe

The European purified terephthalic acid market closely followed its feedstock xylene prices during the given quarter of the year 2023. Hence, because of depreciating crude oil and xylene prices, the purified terephthalic acid prices swung toward the lower end of the price curve. The steady demands from the consumption sectors failed to provide any substantial cost support to the purified terephthalic acid market trend.

North America

Purified Terephthalic Acid price trend also mimicked the sluggishness in the European market during the said period. The rapid decline in crude oil prices in the domestic American market had the biggest impact on regional prices. Overall, low-tottering price trend were witnessed in Q4’23.

Analyst Insight

According to Procurement Resource, the Purified Terephthalic Acid price trend are likely to fluctuate in a narrow range in the coming months. The downfall in crude oil prices is anticipated to have long-term impacts on the Purified Terephthalic Acid market.

PTA (Purified Terephthalic Acid) Price Trend for the July - September of 2023

Asia

The PTA (Purified Terephthalic Acid) market in Asia witnessed a consistent rise throughout the span of the third quarter of 2023. The major consumption of purified terephthalic acid is usually directed towards the production of high-performance multipurpose plastics like PBTs and PETs. So, with high demands from the downstream pharma and plastics industries the purified terephthalic acid prices inclined in the Indian market.

In a similar manner, the Chinese purified terephthalic acid industry also saw a rise of around 5% as the monthly average spot prices rose from about 807 USD/MT to around 853 USD/MT in September 2023. The gradually reviving chemical industry in China contributed significantly to the upward fluctuations in the purified terephthalic acid market. Overall, positive market sentiments were experienced.

Europe

The European purified terephthalic acid market exhibited positive market inclinations during the third quarter of the year 2023. After a very moderate run in the first half of the said quarter, the market dynamics improved substantially in the following half. With a slowly normalizing inflation in the region, the downstream demands for PTA saw significant improvements from the packaging and adhesive industries. Overall, the European purified terephthalic acid market had a good run during the discussed period.

North America

The North American PTA market too reflected the global rising trend during Q3’23. Supported by a positive demand spectrum from the consuming sectors, the purified terephthalic acid market regularly registered rising numbers at the PTA price graph.

Analyst Insight

According to Procurement Resource, the Purified Terephthalic Acid market is projected to rise further in the coming times. A positive demand curve suggests an even better market performance by purified terephthalic acid.

Purified Terephthalic Acid (PTA) Price Trend for the First Half of 2023

Asia

The market dynamics of purified terephthalic acid (PTA) fluctuated in the first quarter of 2023. Initially and towards the end of this quarter, the prices were able to maintain their inclining momentum with the help of rising demand and volatile feedstock costs. During the mid-phase, some of the production units had to shut down, disrupting the supply-demand equilibrium. In the later months of the second quarter, too, the prices took a bearish turn as falling prices of crude oil, oversupply of the product, and fall in demand for purified terephthalic acid (PTA) caused the price trend to move southwards.

Europe

In the first quarter, the purified terephthalic acid (PTA) prices suffered from the rise of inflation rates, disrupted supply chains, and labor strikes. The second quarter, however, took a bullish turn with the help of a rise in the cost of feedstock materials and an increase in the number of sales in the packaging sector initially. Towards the end of this quarter, the number of offtakes from overseas industries declined while the supply remained at a normal level, leading to the shoot in the level of inventories while the price trend of purified terephthalic acid (PTA) declined.

North America

In North America, the purified terephthalic acid (PTA) price trend was supported by the rise in the cost of crude oil and disruptions in the supply chain due to the shortage of labor in the region. The demand from the downstream industries seemed weak during the first quarter but improved significantly in the second, further helping the purified terephthalic acid (PTA) prices maintain their bullish trajectory. In the end phase of this quarter, the trend, however, fluctuated with the limited purchasing potential of buyers.

Analyst Insight

According to Procurement Resource, the price trend of Purified Terephthalic Acid (PTA) is expected to follow a volatile trend as its prices will be dictated by the demand from the downstream sector and the cost of raw materials.

Purified Terephthalic Acid (PTA) Price Trend for the Second Half of 2022

Asia

In the last two quarters of 2022, the price trend of purified terephthalic acid (PTA) suffered due to the sluggish nature of domestic markets. Due to the weak sentiments of the purified terephthalic acid (PTA) market, the traders had to reduce their profit margins, which in turn proved unfavorable for its price trend. There was some relief during the end phase of this quarter, but soon, the demand from the downstream industries declined again. In addition to this, the production of feedstock materials increased, which further boosted the rates of purified terephthalic acid (PTA) production rates amid weak market scenarios that hampered the growth of its prices.

Europe

In the third quarter of 2022, the cost of feedstock materials fell considerably in the European nations, along with the market sentiments of crude oil. Additionally, the demand from the downstream industries also remained weak while the supply chains worked excessively, raising the level of inventories. In the fourth quarter, the demand fluctuated and thus resulted in the volatile nature of the purified terephthalic acid (PTA) price trend.

North America

In the first half of the third quarter, the price trend of purified terephthalic acid (PTA) witnessed a declining trajectory as inventories were high while the demand failed to match the rising rates of supply. In addition to this, consumer confidence also fluctuated during this phase under the pressure of recession and increasing inflation rates.

The situation improved in the second half of this quarter as the cost of production rose significantly. But soon, the adverse effects of poor performance of the packaging sector, large inventory build-up, and downfall of export rates led to the southwards movement of purified terephthalic acid (PTA) price trend.

Analyst Insight

According to Procurement Resource, the price trend of Purified terephthalic acid (PTA) is estimated to decline in the upcoming quarters as the demand from the downstream industries, such as packaging and polymer production, is likely to remain meek while the excess of supply only seems to raise the level of inventories.

Purified Terephthalic Acid Price Trend For the Second Quarter of 2022

Asia

In Chinese markets, PTA prices witnessed a downward trend in H1 of Q2 2022, which gained momentum in the second half of the quarter. Crude oil market remained volatile which in turn affected the prices in the petrochemical markets where the Ex-Qingdao price for PTA hovered at around 1003 USD/MT during June.

As Covid-19 cases resurfaced in China, the operating rate in PTA plants dipped as demand for PET bottles dropped from downstream industries. Meanwhile in India, the market flourished throughout the second quarter, supported by the steady demand for PET bottles from the downstream packaging segments. Since crude oil prices were firm, the market for paraxylene was strong in the regional market.

Additionally, supply constraints were created in the global market as India imported heavily from China and South Korea leading to a surge in price backed by supply chain disruption and climbing transportation costs. The Ex-Silvassa PTA price in India ultimately rose and hovered around 1250 USD/MT in June 2022.

Europe

In the European markets, PTA prices surged during the first half of Q2, which later dropped in the later half by almost 3%. As summer season approached in Europe, demand boosted from end-use industries of Polyethylene Terephthalate (PET) bottle and polyester.

The market was further hit by the crunched supply situation in Europe due to the ongoing Russia-Ukraine conflicts which kept the prices high. Additionally, global crisis abetted the skyrocketing prices in the crude oil market which ultimately affected the prices of all derivatives of petrochemical products. All these factors contributed to the price situation for PTA which fluctuated during Q2 2022 and settled at FD Hamburg 1012 USD per ton in June.

North America

In North American markets, Purified Terephthalic Acid (PTA) prices witnessed an uptrend for the months of April and June, but they later dropped in May supported by the unstable crude oil prices, which remained volatile throughout Q2 2022.

Additionally the prices of upstream raw material like Paraxylene soared high, creating a cost pressure which ultimately contributed to the rising price trend in the first and second half of the second quarter of 2022. In the domestic market, the demand for the chemical remained stable during this period but later caught its pace during June as when demand from downstream industries like packaging sectors surged. The PTA FOB Charleston prices settled at 1033 USD/MT in June.

Purified Terephthalic Acid Price Trend For the First Quarter of 2022

Asia

The prices of PTA have been increasing since the start of this quarter as a result of increased downstream demand and rising pricing pressure from xylene industries. Throughout the first quarter of 2022, demand for downstream polyester and polyethylene terephthalate remained high.

PTA per ton price was recorded at 1084.91 USD (INR 82290) Ex-Kandla at the end of Q1. The Chinese domestic market for Purified Terephthalic Acid has seen an upward trend due to high demand from the downstream PET and textile sectors, as well as rising feedstock prices.

North America

Purified Terephthalic Acid pricing in North America exhibited a seesaw pattern, with prices falling in January, rising in February, and falling again in March. Feedstock prices changed in tandem with the unpredictable crude oil price. The increase in industrial activity led to an increase in demand from consumers and other businesses in PET and polyester markets.

Furthermore, the big producers' revenue and sales have increased in tandem with the increase in consumer consumption. As a result of the rising supply dynamics and solid demand fundamentals, market participants were compelled to lower the prices of available material in the latter stages of Q1. Per ton price of PTA settled at 986 USD towards the end of this quarter.

Purified Terephthalic Acid Price Trend For the Fourth Quarter of 2021

Asia

In October, the Indian market was beset by logistical challenges, posing a significant challenge for dealers and maintaining rising pressure on local PTA pricing. Aside from transportation issues, other factors such as disruptions in production activity in the Chinese market also contributed to the significant spike in PTA prices across the APAC region.

As a result, the price increased dramatically in October, reaching 75,640 INR/MT CFR JNPT. Despite the fact that demand for PTA decreased in the downstream polymer sector in H2 of Q4, demand in other sectors, such as textiles, remained stable across regional markets. PTA prices in India, on the other hand, fell in December due to reduced offtakes from downstream polyester sections.

Europe

Throughout the final quarter, the production was unimpressive, limiting the operating prices of PET resin. PET demand remained high, with market participants remarking that the market had seen some astronomical end-user consumption levels.

The demand for PET resin was pushed up by the increased use of PET bottles in beverages and other uses across the continent. Imports were impeded by high freight costs and long turnaround times. As a result, PTA prices in Europe continued to grow in Q4 and were recorded at 890 USD/MT on a FOB basis in December.

North America

PTA imports from South America remained weak in the fourth quarter. Mexico battled with local manufacturing, which limited exports to the United States, while Asia's exports were hampered by prohibitively high freight and shipping costs.

Likewise, downstream PET resins continued to have robust volume intakes as the packaging industry's demand remained strong. Due to strong demand and uneven supply dynamics, PTA prices were estimated in broad ranges. In December, the FD price jumped to 1170 USD/MT.

Latin America

In October 2021, crude oil exported from Brazil attained an average price 0.5 USD/kg, the highest figure reported in seven years. International oil prices had collapsed in the first months of 2021, due to dramatic reductions in demand as a result of the COVID-19 pandemic. This increased price led to an increase in the price of the chemical, to which petroleum is an important feedstock.

Purified Terephthalic Acid Price Trend For First, Second and Third Quarters of 2021

Asia

The Asia Pacific region's supply chain was bolstered by the inclusion of new PTA plants in China during Q1 2021. Capacity of 7.9 MMT per year started up at the Fujian Baihong facility in Quanzhou, Shenghong petrochemicals in Lianyungang, and Yisheng petrochemicals in Ningbo.

However, the region experienced considerable difficulties as a result of multiple plant turnarounds over the Chinese lunar new year celebrations. Demand was rated solid in the first quarter, as exports to Western Europe and imports from Southeast Asia increased. FOB Shanghai prices increased steadily throughout the quarter, averaging 908 USD/MT for April delivery.

The Asia Pacific region's supply outlook exhibited a mixed pattern in the second quarter of 2021, owing to a wide range of developmental turnarounds in China and Northeast Asia, which tightened overall product supply following a period of expansion in the first half of the quarter.

Yinsheng Petrochemical, a renowned PTA maker in China, commissioned two new PTA facilities in May. Additionally, Yinsheng Petrochemicals announced the permanent shutdown of its oldest 650 KTPA line in Zhejiang province due to higher production margins on its new PTA lines. Taking into account the sequence of capacity additions, China is expected to increase its PTA capacity by an additional 3.3 MMT in H2 2021.

Against the backdrop of already stretched supplies, market participants were keenly monitoring changes in Indian consumer demands as the second wave of pandemic impacted the largest Asian PTA importer's demand. China's pricing trend remained stable, with FOB Qingdao prices averaging 859 USD/MT in June.

In Asia, PTA prices continued to rise in the third quarter of 2021, owing to strong offtakes from local downstream manufacturers and an increase in upstream pricing. In India, the outlook for the market was bright, owing to robust demand from the PBT and PET industries, despite constrained supply conditions.

Additionally, delayed supply followed by congestion at various Chinese ports, as well as expensive imports from other nations due to excessive freight charges and a lack of shipping containers, all contributed to the region's PTA price inflation. Thus, during July and September, PTA prices increased to 467.38 USD/MT from 360.44 USD/MT.

Europe

Supplies in Europe were scarce in Q1 2021, owing to hindered transportation in the northwest European region, which resulted in a shortage of critical feedstocks. The production declined significantly at the PKN Orlen facility in Poland, followed by an unforeseen outage at the INEOS PTA complex in Belgium.

Additionally, shipments to the region decreased during the third quarter due to the Suez Canal blockade and high transportation costs. However, as a result of the disturbance in the supply chain, demand from the downstream PET industry increased significantly in Q1 2021.

The European market's supply situation improved over the last quarter, as an upstream paraxylene unit completed its turnaround phase in the second quarter. However, due to its limited stock availability in the US market, export quantities to Europe decreased. Several South Korean PTA exporters were heard moving significant amounts to the European markets in order to leverage these nations' Free Trade Agreements.

Freight charges in the Atlantic region decreased, resulting in a strengthening of the arbitration window between Europe and North America. The resumption of market activity aided public movement in numerous regions of Europe, which resulted in an increase in the chemical’s demand from the textile industry.

The PTA market in Europe remained stable in the third quarter of 2021. PTA prices tracked the values of feedstocks, which were elevated throughout the quarter. Numerous reasons contributed to this, including postponed imports due to supply chain disruptions and lower production during this period, followed by Europe's natural gas crisis. Additionally, rising freight costs weighed on PTA values in this quarter.

North America

The North American market remained constrained in the first quarter of 2021, owing to production difficulties caused by the unusual arctic freeze in the US Gulf area. Due to plant shutdowns, the dramatic weather conditions resulted in the shortage of critical feedstock for several weeks.

Demand from the downstream PET market increased significantly, owing to intense competition among buyers to refill their stockpiles in anticipation of anticipated demand growth in the coming years. PTA prices increased in response to the rise in the cost of upstream benzene and paraxylene.

PTA shipments in the North American region improved significantly over the first quarter, owing to the restoration of industrial infrastructure along the US Gulf coast and the operation of large manufacturing facilities at peak efficiency. Despite this, regional supplies remained scarce in the second quarter of 2021 as a result of the disrupted imports.

Mexican PTA trade contracted in the second quarter as inventories were bolstered ahead of the forthcoming storm season in North America. Demand was bolstered by downstream polyester businesses, which saw a seasonal surge in offtakes due to the increase in textile manufacture. As a result, the price increased, with FOB Texas negotiations settling at 1250 USD/MT, a 17.92% increase in the month of June alone.

During the third quarter of 2021, the chemical’s values remained stable in the North American region. Factors such as a shortage of raw materials and high demand from the manufacturing industry following the economic recovery pushed the pricing curve upward.

Disruptions to manufacturing and supply lines caused by Hurricane Ida, which made landfall on the United States Gulf Coast in August, exacerbated the region's supply shortage. Additionally, logistical challenges, particularly truck availability, resulted in delays in product deliveries in the region, contributing to the PTA pricing trend. During the quarter, prices were assessed in the 1110-1150 USD/MT FOB Texas range.

Purified Terephthalic Acid Price Trend For the Year 2020

Asia

Purified Terephthalic Acid (PTA) became 10% cheaper in the first week of January 2020, providing significant relief to synthetic yarn manufacturers following the temporary stoppage of imports from China due to the outbreak of coronavirus.

The elimination of anti-dumping duties on this essential synthetic textile raw ingredient resulted in its reduction in price in India. PTA prices were recorded at 600-620 USD/MT. The prices are decided by crude oil prices. In the near term, the Asia Pacific region's supply glut of the chemical lessened as numerous manufacturers in China and India implemented a temporary shutdown in response to waning fears about coronavirus spread and falling polyester demand.

However, the approaching start-up of new PTA capacity in China put manufacturers and merchants under pressure due to excess production in times of lingering downstream demand.

Europe

As the European region resumed activities at a steady pace following a significant increase in lockdown restrictions, demand from the polyester and plastic industries saw a much-needed resurgence following a prolonged period of dormancy in the previous quarter.

Better market dynamics were obscured in the following months by a rise of PTA cargoes from the Asian region as a result of China's planned capacity increases. Concerns over the reemergence of coronavirus in several parts of Europe also put doubt on the chemical’s near-term demand prognosis.

North America

The North American market benefited significantly from growing demands for packaging materials as a result of escalating coronavirus. Increased demand as a result of a favorable shift in consumer attitudes toward single-use plastics benefited the US PTA business significantly.

The local market was unexpected to experience significant demand issues as long as the aluminum scarcity prevailed. However, the extended slump in the polyester industry slowed down the market's growth in the packaging sector.

Latin America

Crude oil prices fell globally during early months of 2020, following the commencement of the COVID-19 epidemic. With transportation and industrial activity almost halted, the global demand for crude oil fell to an all-time low. Due to the decreased crude oil prices and a downfall in demand, PTA prices also reduced.

Procurement Resource provides latest prices of PTA (Purified Terephthalic Acid). Each price database is tied to a user-friendly graphing tool dating back to 2014, which provides a range of functionalities: configuration of price series over user defined time period; comparison of product movements across countries; customisation of price currencies and unit; extraction of price data as excel files to be used offline.

About Purified Terephthalic Acid

PTA or Purified Terephthalic Acid, a white coloured solid, is an organic compound that mainly serves as a commodity chemical. It is used as a raw material to produce high-performance multipurpose plastics like polybutylene terephthalate (PBT), polyethylene terephthalate (PET), polytrimethylene terephthalate (PTT) and even forms of bioplastics.

Purified Terephthalic Acid Product Details

| Report Features | Details |

| Product Name | PTA (Purified Terephthalic Acid) |

| CAS Number | 100-21-00 |

| Industrial Uses | Intermediate and precursor, Polyester fibres, Adhesives and sealant chemicals, Lubricants , Paints and coatings, Plasticisers , Pharmaceuticals, Metal-organic frameworks |

| Chemical Formula | C8H6O4 |

| HS Code | 291736 |

| Molecular Weight | 166.13g/mol |

| Supplier Database | Reliance Industries Limited (RIL), Saudi Basic Industries Corporation (SABIC), Alpek S.A.B. de C.V., BP p.l.c., Eastman Chemical Company |

| Region/Countries Covered | Asia Pacific: China, India, Indonesia, Pakistan, Bangladesh, Japan, Philippines, Vietnam, Iran, Thailand, South Korea, Iraq, Saudi Arabia, Malaysia, Nepal, Taiwan, Sri Lanka, UAE, Israel, Hongkong, Singapore, Oman, Kuwait, Qatar, Australia, and New Zealand Europe: Germany, France, United Kingdom, Italy, Spain, Russia, Turkey, Netherlands, Poland, Sweden, Belgium, Austria, Ireland Switzerland, Norway, Denmark, Romania, Finland, Czech Republic, Portugal and Greece North America: United States and Canada Latin America: Brazil, Mexico, Argentina, Columbia, Chile, Ecuador, and Peru Africa: South Africa, Nigeria, Egypt, Algeria, Morocco |

| Currency | US$ (Data can also be provided in local currency) |

| Supplier Database Availability | Yes |

| Customization Scope | The report can be customized as per the requirements of the customer |

| Post-Sale Analyst Support | 360-degree analyst support after report delivery |

Note: Our supplier search experts can assist your procurement teams in compiling and validating a list of suppliers indicating they have products, services, and capabilities that meet your company's needs.

Purified Terephthalic Acid Production Process

- Production of PTA (Purified Terephthalic Acid) from p-Xylene via Amoco Process

p-Xylene serves as the feedstock for Terephthalic Acid production. In the Amoco process, p-xylene is oxidised in the presence of a cobalt–manganese–bromide catalyst, which gives Terephthalic Acid as the result.

Methodology

The displayed pricing data is derived through weighted average purchase price, including contract and spot transactions at the specified locations unless otherwise stated. The information provided comes from the compilation and processing of commercial data officially reported for each nation (i.e. government agencies, external trade bodies, and industry publications).

Assistance from Experts

Procurement Resource is a one-stop solution for businesses aiming at the best industry insights and market evaluation in the arena of procurement. Our team of market leaders covers all the facets of procurement strategies with its holistic industry reports, extensive production cost and pre-feasibility insights, and price trends dynamics impacting the cost trajectories of the plethora of products encompassing various industries. With the best analysis of the market trends and comprehensive consulting in light of the best strategic footstep, Procurement Resource got all that it takes.

Client's Satisfaction

Procurement Resource has made a mark for itself in terms of its rigorous assistance to its clientele. Our experienced panel of experts leave no stone unturned in ensuring the expertise at every step of our clients' strategic procurement journey. Our prompt assistance, prudential analysis, and pragmatic tactics considering the best procurement move for industries are all that sets us apart. We at Procurement Resource value our clients, which our clients vouch for.

Assured Quality

Expertise, judiciousness, and expedience are the crucial aspects of our modus operandi at Procurement Resource. Quality is non-negotiable, and we don't compromise on that. Our best-in-class solutions, elaborative consulting substantiated by exhaustive evaluation, and fool-proof reports have led us to come this far, making us the ‘numero uno' in the domain of procurement. Be it exclusive qualitative research or assiduous quantitative research methodologies, our high quality of work is what our clients swear by.

Related News

Table Of Contents

Our Clients

Get in Touch With Us

UNITED STATES

Phone:+1 307 363 1045

INDIA

Phone: +91 8850629517

UNITED KINGDOM

Phone: +44 7537 171117

Email: sales@procurementresource.com

-to-lintas-citra-pratama.webp)