Product

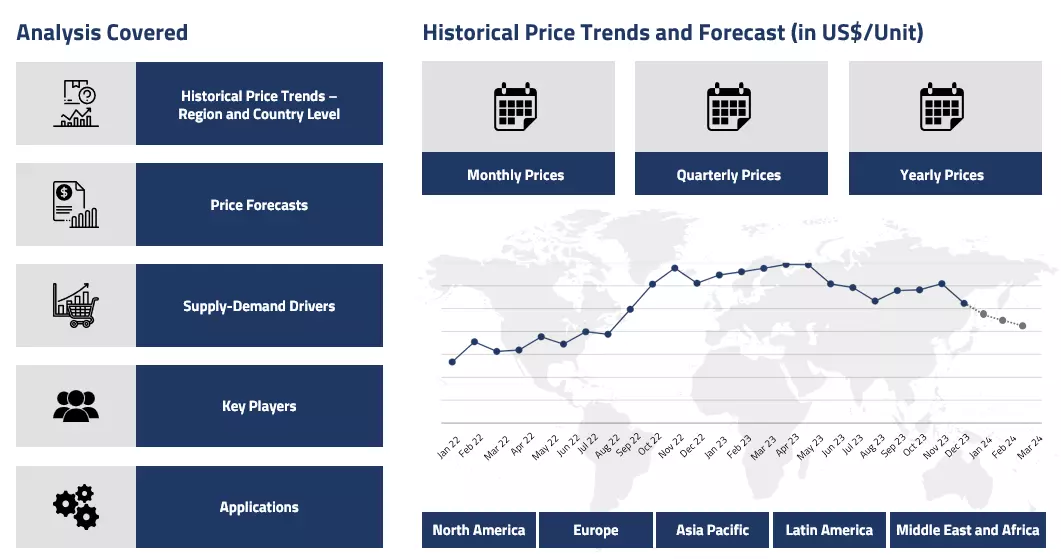

Styrene Price Trend and Forecast

Styrene Price Trend and Forecast

Styrene Regional Price Overview

Get comprehensive insights into the Styrene market, with a focused analysis of the Styrene price trend across Asia, Europe, North America, Latin America, and the Middle East & Africa.

Styrene Price Trend for Q1 of 2025

Asia

In Asia, particularly China, styrene prices exhibited a volatile pattern throughout Q1’25. January began with a sharp decline due to excessive inventory accumulation at major East China ports and increased domestic supply following the restart of key production units. By mid-January, prices rebounded slightly as pre-Lunar New Year restocking provided limited support.

Styrene Price Chart

Please Login or Subscribe to Access the Styrene Price Chart Data

February saw modest recovery driven by gradual inventory reduction and improved demand from the downstream sectors. However, March experienced another downturn as high port inventories persisted and market sentiment weakened despite some downstream buyers entering on price dips. Demand from ABS remained consistently underwhelming throughout the quarter, limiting price recovery potential in the region.

Europe

European styrene markets faced significant challenges in Q1’25, primarily influenced by supply chain disruptions. The permanent closure of LyondellBasell and Covestro's production unit in the Netherlands created supply constraints, particularly impacting Western European markets. Despite these supply-side constraints, prices remained relatively stable as subdued industrial demand, particularly from construction and automotive sectors, offset potential price hikes. Market participants adopted cautious purchasing strategies throughout the quarter, preferring just-in-time buying over building substantial inventories.

North America

North American styrene markets experienced downward pressure throughout Q1’25. Early January saw relatively stable prices, but the market gradually slowed as winter progressed. By March, market sentiment had turned decisively cautious, with prices declining steadily. This trend was influenced by fluctuating crude oil prices, weak downstream demand across sectors, and increased inventory levels. Producers in the region faced margin pressure as they struggled to pass increased production costs to consumers amid competitive market conditions.

Analyst Insight

According to Procurement Resource, Styrene markets are expected to see gradual stabilization with potential modest growth in Q2’25, supported by seasonal demand improvement and possible inventory normalization.

Styrene Price Trend for Q4 of 2024

| Product | Category | Region | Price | Time Period |

| Styrene | Chemicals | China | 1262 USD/MT | October'24 |

| Styrene | Chemicals | China | 1217 USD/MT | December'24 |

| Styrene | Chemicals | India | 1184 USD/MT | October'24 |

| Styrene | Chemicals | India | 1144 USD/MT | December'24 |

Stay updated with the latest Styrene prices, historical data, and tailored regional analysis

Asia

The styrene market in Asia followed a downward trend throughout Q4 of 2024. In China, prices remained stable at the beginning of the quarter but gradually declined due to weak demand from downstream industries such as polystyrene and ABS. This decline was further pressured by ample domestic inventories and reduced export opportunities, limiting any price recovery. Toward the end of the quarter, seasonal factors, including reduced industrial activity during the holiday period, contributed to further price softening. Monthly average prices in China were approximately 1262 USD/MT in October and declined to around 1217 USD/MT in December.

India experienced a similar downward trajectory. Styrene prices in the Indian market stood at about 1184 USD/MT (CFR) in October and dropped to around 1144 USD/MT in December. The price graph showed a gradual decline in October, but as the quarter progressed, weak demand and steady import volumes further pressured prices. The last two months of the year saw seasonal slowdowns and limited procurement activity, leading to continued price declines.

Europe

Europe's styrene market exhibited a fluctuating trend with a general downward bias in the fourth quarter of 2024. Early in the quarter, prices saw a slight increase due to short-term supply disruptions and a modest rise in demand from the construction and automotive industries ahead of the festive season. However, as the quarter progressed, demand weakened due to seasonal slowdowns and declining industrial output, particularly in the final months.

Downstream industries, including polystyrene and resins, reduced production due to lower consumer demand and inventory liquidation before the year's end. Although intermittent fluctuations occurred due to wavering feedstock costs, the overall market maintained a bearish outlook throughout the quarter.

North America

During the last quarter, in the North American region, the styrene market underwent similar shifts as its other global counterparts. At the start of the quarter, prices were supported by robust demand from downstream sectors. However, as the festive season approached, it caused a typical seasonal slowdown, with less industrial activity followed by a softening of the demand for the commodity. The styrene price graph witnessed downward movements by the end of the quarter as a result of weak demand and limited trading activity.

Analyst Insight

According to Procurement Resource, the styrene price graph is expected to show similar movements in the near future, influenced by the fluctuating prices in the upstream market.

Styrene Price Trend For the Q3 of 2024

| Product | Category | Region | Price | Time Period |

| Styrene | Chemicals | China | 1300 USD/MT | September’24 |

| Styrene | Chemicals | India | 1156 USD/MT | September’24 |

Stay updated with the latest Styrene prices, historical data, and tailored regional analysis

Asia

The Asian market observed an oscillating trend in the pricing patterns of styrene. Initially, the prices in July kept stable and steadily inclined till august. Although the prices of feedstock benzene were falling it did not impact the styrene pricing fundamentals immediately. Many of the styrene manufacturing plants were under maintenance in China which less to shortage of styrene inventories in the market thereby, aiding the price increase. However, soon production ran at full capacities only to meet with the tepid demands from the downstream industries.

The fractured terminal demand caused the buyers to adopt a wait-and-see attitude which impacted the overall styrene pricing dynamics leading to price to fall in September. The styrene prices averaged around 1300 USD/MT (spot) in the Chinese market during September’24. Almost a similar trend was seen in the Indian market where the prices averaged 1156 USD/MT (CFR) in September’24.

Europe

The European styrene market fluctuated throughout the quarter, ending with a downward trend in September. Early strength was due to firm feedstock costs; however, soon the poor demand and low stock levels pressured prices downward. The narrowing benzene-styrene spread, approaching break-even production costs, further contributed to the falling trend.

North America

The U.S. styrene market showed volatility before trending downward in September. August began with a price increase, quickly reversed due to excess supply and reduced demand from automotive and construction sectors. The market faced ongoing supply-demand imbalances, making it difficult for producers to stabilize prices. As September approached, a slight recovery was seen before resuming the downward trajectory, influenced by year-end industrial slowdowns and broader economic challenges.

Analyst Insight

According to Procurement Resource, the Styrene market to remain volatile in the coming months, with a continued downward pressure on prices. The global market's fragility and ongoing uncertainties across various sectors are likely to keep impacting the styrene industry.

Styrene Price Trend for the Q2 of 2024

Asia

In Q2 2024, the styrene market in Asia displayed resilience and stability despite some initial fluctuations. In China, after a slight drop in early May, styrene prices gradually recovered, driven by increased industrial activity and higher costs for base materials like benzene and ethylene. The last month of the quarter also saw market stabilization with modest price increases due to rising consumer spending, steady feedstock benzene costs, and growing freight charges. Additionally, the demand for styrene remained positive across sectors such as packaging, automotive, construction, and electronics. Despite supply-side pressures from plant shutdowns, continuous import activities ensured a steady supply, contributing to market stability.

Similarly, in Japan, the styrene market stabilized towards the end of May and into June; the momentum was supported by strong demand from key industrial sectors and improving manufacturing conditions. The styrene prices, although they experienced initial volatility, settled as industrial activity accelerated, particularly in the packaging, automotive, and construction sectors.

Europe

In Q2 2024, the European styrene market mirrored the mixed trends of benzene prices and the weak outlook of its downstream industries. With ample benzene supply and moderate demand from end-use manufacturing, the excess production of benzene widened the supply-demand gap, exerting downward pressure on styrene prices.

The decline in naphtha prices, a key benzene feedstock, further contributed to this trend as cheaper European naphtha boosted exports to Asia. Additionally, reduced energy prices and lower industrial goods pressure eased inflation in Europe, influencing the styrene market. Anticipated slower economic growth due to interest rate hikes by the ECB and the Bank of England further dampened demand for benzene derivatives, including styrene, leading to a cautious market outlook.

North America

In Q2 2024, the U.S. styrene market exhibited notable fluctuations, reflecting the complex interplay of economic factors and industry dynamics. After showing resilience in the first month of the second quarter, in May, styrene prices declined due to a temporary surplus and reduced demand from construction and automotive sectors, impacted by supply chain disruptions and shifting consumer preferences.

However, mid-May saw a price increase driven by an improvement in demand from the packaging and appliance industries, supported by increased consumer spending and downstream manufacturing activities. The rise in styrene costs was further fueled by increased prices for base materials like benzene and ethylene, along with higher energy and labor costs, leading to inflationary pressures on producers. The supply chain bottlenecks and logistical challenges further escalated these cost pressures.

Analyst Insight

According to Procurement Resource, the price trend of Styrene is estimated to fluctuate as styrene market's outlook appears uncertain, influenced by inflation, interest rates, and geopolitical factors that could further impact supply chains and global demand.

Styrene Price Trend for the Q1 of 2024

| Product | Category | Region | Price | Time Period |

| Styrene | Chemicals | USA | 998 USD/MT | January 2024 |

| Styrene | Chemicals | USA | 1018 USD/MT | March 2024 |

| Styrene | Chemicals | China | 1209 USD/MT | January2024 |

| Styrene | Chemicals | China | 1291 USD/MT | March 2024 |

| Styrene | Chemicals | India | 1206 USD/MT | January2024 |

| Styrene | Chemicals | India | 1257 USD/MT | March 2024 |

| Styrene | Chemicals | Europe | 1042 USD/MT | March 2024 |

Stay updated with the latest Styrene prices, historical data, and tailored regional analysis

Asia

Styrene prices were found to be consistently inching higher in the Asian markets during the said period of Q1’24. In the Chinese markets, the monthly average prices inclined by approx. 6% as they moved from about 1209 USD/MT in January’24 to around 1291 USD/MT in March’24. The biggest reason behind this upsurge in prices was the global incline in petroleum prices.

The OPEC+ limited its output, which impacted the whole petrochemical industry in general. However, the Changzhou New Solar Chemical and Anhui Jiaxi New Material have restarted their styrene monomer plants with a capacity of 350 KMTA each in March’24, which underwent maintenance shutdown in January’23 and December’23, respectively. These operations will help to balance the supply equation a little in the coming months. Following a similar inclined trajectory, the monthly average prices in the Indian markets also went from about 1206 USD/MT (CFR) in January’24 to around 1257 USD/MT in March’24; this raised the market by around 4% in the country.

Europe

Styrene prices fluctuated throughout the given span in the European market. The prices first slid marginally, driven by the dull demands in the early months of the year. However, rebounded quickly as some companies decided to raise their base prices to counter the rising processing costs and declining supplies.

The prices averaged around 1042 USD/MT (CIF) in the European domestic market for the majority of the said period. Trinseo announced a price hike for its styrene and associated products in mid-Feb after permanently shutting down its 500 KTPA styrene plant in Terneuzen back in November’23 as a part of the company’s restructuring plan. Repsol shut its 450 KTPA styrene unit in Tarragona in January for planned maintenance. These changes in the supply equation also drove the market uphill. Overall, an upward-moving price graph was observed in Q1’24.

North America

The surge in the global styrene market and the supply chain disturbances drove the styrene market uphill in the American market as well. Prices soared as the freight and logistics issues kept mounting up. Average monthly prices saw a 2% incline as they went from around 998 USD/MT in January’24 to about 1018 USD/MT in March’24.

The feedstock benzene costs were consistently inching higher, which raised the production costs for styrene in the given quarter. Similarly, the companies also raised their product prices as the shipping charges started surging globally because of the Red Sea crisis. Overall, a very positive market performance was witnessed during the given timeframe.

Analyst Insight

According to Procurement Resource, considering the heat in the petrochemical sector. Styrene prices will remain on the rising spree in the coming quarter as well. Market projections look very optimistic going forward.

Styrene Price Trend for the October - December of 2023

| Commodity | Sector | Region | Price | Time Period |

| Styrene | Chemical | North America | 1000 USD/MT | January 2024 |

| Styrene | Chemical | North America | 1035 USD/MT | December’23 |

| Styrene | Chemical | North America | 1078 USD/MT | October’23 |

| Styrene | Chemical | Europe | 1028 USD/MT | December’23 |

| Styrene | Chemical | Europe | 1168 USD/MT | October’23 |

| Styrene | Chemical | India | 1203 USD/MT | December’23 |

| Styrene | Chemical | India | 1217 USD/MT | October’23 |

| Styrene | Chemical | China | 1172 USD/MT | December’23 |

| Styrene | Chemical | China | 1214 USD/MT | October’23 |

tay updated with the latest Styrene prices, historical data, and tailored regional analysis

Asia

The Asian styrene market was witnessed to fluctuate during the given period of Q4'23. However, the slowdown in its feedstock toluene and methanol markets was reflected in the styrene's price trends as well. In the Chinese styrene market, the average monthly spot prices stood at around 1214 USD/MT in October '23 and ended up at about 1172 USD/MT in December '23. This led to a decline of about 3% in the Chinese styrene market during the said quarter.

On the other hand, in the Indian styrene market, the prices first moved up slightly in the first half of the quarter, only to decline in the latter half. The monthly average prices went from about 1217 USD/MT (CFR, India) in October '23 to around 1203 USD/MT in December '23. So, very narrow-ranged oscillations were observed in the Indian styrene market throughout the said period.

Europe

The European styrene market exuded the sluggishness of the global styrene market during the given period. Considerable fall in crude oil prices drove these market trends. The styrene prices averaged at around 1168 USD/MT (CFR) in October and fell to about 1028 USD/MT by December '23. This led to a swift depreciation of about 11% in the regional styrene prices in the domestic market.

North America

The North American market trends for styrene were no different than its Asian and European counterparts. The prices here, too, followed a downward-facing trajectory during Q4'23. The monthly average prices went from about 1078 USD/MT (CIF) in October '23 to around 1035 USD/MT in December '23, imparting an approximate downfall of about 3%. Overall, slumping market trends were witnessed in Q4'23. The current bearish trends are expected to continue in the coming month, given the demand trajectories, and the prices are expected to average around 1000 USD/MT in January '24.

Analyst Insight

According to Procurement Resource, Styrene price trends are expected to witness regional variations in the coming months. The crude oil prices and the downstream demands will drive the market trends.

Styrene Price Trend for the July - September of 2023

Asia

In India, the inclination in the prices of styrene was approximately 12%, while that in China was around 21%. This strong rise in the styrene price trend was caused by a rise in consumption rates of consumers and a shift in their spending appetite. Further, the supply chains faced several disruptions that negatively influenced the inventory levels and reduced the influx of products in the region amid high demand. In addition to this, the rise in the cost of crude oil, substantial cuts in exports and production of petrol, and a hike in input costs resulted in the northward movement of styrene price trend in the third quarter.

Europe

In Europe, similar to the styrene market growth in Asia Pacific countries, the rise in competition and elevated cost of crude oil led to the rise in the trajectory of the styrene price graph. This upswing was also a direct consequence of the high number of offtakes from overseas players. In July, the styrene prices stood at around 1089 USD/MT (CIF, Europe), and then with the help of the rise in demand and overall positive momentum of the downstream industries, they grew to around 1130 USD/MT(CIF, Europe) in September.

North America

The styrene price trend followed the same trajectory as that was seen in the European and Asia Pacific countries. Here, the northward movement of the prices was influenced by the rise in the cost of crude oil and improving economic indicators. The market also saw a reduction in inflation rates and a slowing down of interests charged by the banks that expanded the spending budget of consumers and thus helped in the rise in the styrene price trend.

Analyst Insight

According to Procurement Resource, the price trend of Styrene are estimated to continue its inclining trajectory, which is the result of the growth of the downstream industries and the strong recovery of the global economy.

Styrene Price Tends for the First Half of 2023

Asia

The styrene market witnessed a gradually declining trend as the spot prices in China fell from approximately 1223 USD/MT in January to around 1060 USD/MT in June’23. The major reason for this decline was that the manufacturers were forced to reduce their production rates amid weak demand from the polymer market. As a result, the stockpiles of the products increased in the region. To further aid this dip in the prices, the re-imposition of covid restrictions and labor strikes in South Korea hampered the supply chain of Styrene in the region.

Europe

In the first two quarters of 2023, the price trend for Styrene in the European market declined. The region witnessed volatility in the upstream costs and southward movement of demand for the product, negatively impacting the price trend of Styrene. In addition to this, the employment rate also dipped. The rising energy rates and wavering production costs further fueled the downward movement of styrene prices in Europe.

North America

In North America, the prices fluctuated throughout the first and second quarters of 2023. The trend was majorly affected by the crude oil prices and the significant gap between the demand and supply sectors. The shortage of labor and disruptions in the supply chains also led to uncertainties in the styrene market. Additionally, the purchasing tendency of the buyers was also affected, which led to the plunge in the prices of Styrene in the region.

Analyst Insight

According to Procurement Resource, the prices of Styrene are estimated to remain unsettled in the upcoming months. As the demand and supply gap widens with the rising energy costs and regional imbalances, the styrene price trend will take a long time to recover.

Styrene Price Trend for the Second Half of 2022

Asia

The Asian market in the last two quarters of 2022 did not support the rise in the prices of Styrene. The most influencing factor was the drop in the prices of feedstock materials and the slow product movement of the Asian market. The trend was also affected by the depreciation of Asian currency in comparison to the US dollar and feeble demand from the downstream industries.

Europe

In Europe, the price trend for Styrene fluctuated in the third and fourth quarters of 2022. The prices declined as a result of the volatility in crude oil costs and gradually falling demand in the domestic and international markets. Along with this, the rising inflation and dip in the prices of styrene-derived products also adversely impacted the styrene market.

North America

The styrene market in North America moved southward in the third and fourth quarters of 2022. The dip in the prices was caused by the abundant supply of the product in the region, along with decreasing crude oil prices. The automotive sector, one of the significant market drivers of Styrene, also showcased slow movement and thus less demand for the product aiding the fall of the prices.

Analyst Insight

According to Procurement Resource, the prices of Styrene are estimated to decline in the upcoming quarter. The slow demand and falling crude oil prices are expected to impact the styrene market negatively.

Styrene Price Trend For the Second Quarter of 2022

Asia

Styrene prices saw a rise in the Asia-Pacific region as the quarter came to an end. In April, the price quotations were tagged at 1360 USD/MT, CFR Shanghai, and in June, they were marked at1470 USD/MT, CFR Shanghai. Since lockdown was imposed in major cities, one of the major producers of styrene suffered from transport restrictions and supply was limited for the entire quarter. Even though these regulations were in effect, the demand from the packaging industry persisted, and as a result, styrene's domestic market sentiment was proportionally regulated.

North America

Due to rising demand, market views for styrene in the North American market continued to be favorable in the second quarter. Since styrene prices were recorded at 2150 USD/MT, FOB Texas in March, the price change happened at the conclusion of the second quarter. As demand from upstream industries surpassed supply in the North American market, crude oil prices surged. The downstream benzene and ethylene prices increased as a result, which had an adverse effect on the price of styrene in the local market.

Europe

The European Styrene market continued to grow consistently in the second quarter of 2022. Between April and June, the styrene prices ranged from 1938 USD/MT, CFR Hamburg to 1940 USD/MT, CFR Hamburg. The European Union's crude oil sanctions resulted in a supply deficit for the major producers of styrene.

The regional market's benzene and ethylene prices rose accordingly as a result of this scarcity, which had an effect on market for styrene.Styrene prices were impacted by the exaggerated production activity of European nations throughout the second quarter.The market segments for the polymer continued to be governed by the demand for food containers, packaging, and cars.

Analyst Insight

According to Procurement Resource, the prices for styrene can be expected to hit harshly in the year's second half. The drab demands from the end-user industry, languid feedstock prices, and soaring inflation rates could be held culpable in the passive price trend for styrene monomer globally.

Styrene Price Trend For the First Quarter of 2022

Asia

Styrene prices shot up in China in March 2022 with the rise in crude oil prices due to the Russia-Ukraine war. Styrene futures market rose to 9977 RMB/MT while the Jiangsu spot prices rose to 9795 RMB/MT. The maintenance units were back in use and ready to be restarted along with several new units to be put on operation. Even though demand for styrene from downstream construction industry was weak, prices rose significantly with the rise in crude oil prices.

Europe

Styrene spot prices rose consistently in the beginning of March due to disruptions in supply chain and bullish upstream markets while limited imports kept the prices high in Germany. The CFR Hamburg prices in the first week of March were around 1650 USD/MT. While the supply situation seemed to recover, the Ukraine-Russia war impacted the crude oil prices thereby affecting the prices of ethylene, benzene and styrene which continued to increase as the market supplies grew tight.

North America

The price in the North American market showed strong pace in the first quarter of 2022, rising from 1406 USD/MT FOB Texas in January to 1650 USD/MT FOB Texas by the conclusion of the quarter. As a result of the war between Russia and Ukraine, escalating styrene prices in the US market were accompanied by increasing crude oil prices. The cost of manufacturing for major producers increased, affecting market sentiments for the monomer. The demand prognosis for downstream packaging, automotive, and rubber industries remained positive, and as a result, styrene prices increased in Q1 2022.

Styrene Price Trend For the Fourth Quarter of 2021

Asia

Styrene prices remained flat in Q4 compared to Q2 and Q3. Additional domestic production and sluggish demand in the import market were viewed as putting pressure on India's and China's key styrene industries. Because of the plentiful supply, feedstock benzene prices were dropped, and market trade activity slowed. India's solid demand for automobiles and household appliances persisted, and the downstream market remained stable, with customers purchasing products on a need-to basis and anticipating additional price reductions.

Prices were 1269 USD/MT Ex-Vadodara in the last week of December, while prices in China were 1340 USD/MT FOB Qingdao. Due to the strong supply possibilities, a delay in planned maintenance of Zhejiang Petroleum & Chemical Styrene facility, as well as the restart of another styrene unit with 600 KTPA capacity, has put a strain on regional market fundamentals.

Europe

Stockpiling of styrene inventory and oversupplies lowered the prices in Europe in the fourth quarter. In Germany, sentiment appeared to be skewed due to weak demand. Expansive production edges had been viewed as an additional cost of styrene production up to this point, owing to crucial production interruptions in the fourth quarter that left the stockpiles vulnerable.

As a result of the lower demand, benzene inventories have been steadily increasing. Furthermore, the high freight cost had reduced arbitrage opportunities, leaving the European market with a glut of material and few outlets. In Q4 2021, supplies will be depleted, resulting in a steeply backward pricing curve. According to reports, the margin for styrene over benzene in the downstream market was broader in November, with the gap exceeding 500 USD/MT for the month, although a spread of 250 USD/MT normally signified a well-balanced market.

North America

Due to good demand and strong downstream sectors, styrene prices in North America remined on the higher end when compared to Q2 and Q3. In October, US exports to the world declined by more than 9% due to rising freight charges on key US trade routes and a drop in demand from key export destinations, according to a monthly analysis of the market.

Exports fell to 121,854 MT in October, according to data from the International Trade Centre (ITC). However, in lieu of growing trading and domestic use, some countries imported bigger volumes of US styrene. In October, Mexico upped its imports of US styrene to 80,595 MT. Meanwhile, prices were relatively consistent in H2 of Q4, and according to evaluations from the second week of December, US pricing increased by 3% on a FOB basis, indicating early symptoms of a market change.

Styrene Price trend For First, Second and Third Quarters of 2021

Asia

Supplies in the APAC area exhibited mixed results in the first quarter, as numerous plants' turnarounds came to a conclusion and producers worked at optimum efficiency. Several manufacturing facilities in Japan, however, were forced to shut down their operations due to power disruptions induced by the earthquake in early February. Meanwhile, demand soared in the region as demand for ABS increased, and the downstream packaging industry thrived. Styrene prices in India surged during the quarter, maintaining an average of 1084.5 USD/MT CFR JNPT due to increased demand from downstream sectors such as ABS and Polystyrene.

The supply improved in the second quarter of 2021, thanks to LyondellBasell's establishment of a new SM/PO facility in China, as well as the release of force majeure at numerous styrene manufacturing sites in the APAC area. However, despite the impact of India's second COVID wave, which curtailed industrial and commercial activities owing to a partial lockdown, buying in the Southeast Asian region remained modest.

In China, demand increased due to an influx of inquiries from downstream Polystyrene and ABS manufacturers and was claimed to have reached pre-pandemic levels in Q2. However, growing inflation and the enforcement of consumption taxes on imported heavy aromatics commodities made dealers wary, and they were hesitant to purchase high-cost raw materials. Throughout the quarter, the pricing trend remained consistent, with FOB Shanghai prices closing at 2015 USD/MT in June.

Dull buying sentiments in Asia drove down styrene prices in Q3. The polymer’s market prospects remained dim as a result of port restrictions in various nations, which restricted normal trading activity in the aftermath of the development of delta variant cases in the region. As a result of the vendors' battle to get the material, styrene prices increased. Several Asian facilities experienced a temporary maintenance shutdown, putting additional strain on supply fundamentals. As a result, the market trend in India shifted upward, with prices rising from 1183 USD/MT to 1418 USD/MT Q3 2021. Even among Chinese players, the constant increase in demand from China amid crippled supply activities continued to drive up styrene prices.

Europe

During the first quarter of 2021, supplies were scarce as a key styrene-producing factory remained closed in early February, followed by poor industrial and commercial activity amid fears of a second COVID-19 pandemic wave. High demand, on the other hand, led in a massive increase in styrene prices, despite the supply. As traders reported depleted pre-stocked inventories and delayed imports, the quarterly pattern is expected to continue.

At the start of the second quarter, run rates for the monomer increased at various manufacturing units. The supply forecast in the European region improved over the previous quarter, thanks to stronger run rates reported by numerous SM producers, while demand was reinforced by increased inquiries from downstream building and construction units amid the economic recovery. Offtakes were stable from the ABS and Polystyrene manufacturing operations, which ramped up production to meet increased end-use demand and Middle Eastern exports.

Benzene pricing trend measured optimistic attitudes in European countries during Q3. The strong price of benzene, feedstock, resulted in a price increase for practically all styrenics. The downstream building and construction sectors increased their demand for the monomer in September. Throughout the quarter, offtakes from the ABS and Polystyrene production plants were steady. In September, the price in Germany was set at 1340 USD/MT.

North America

Supplies in the North American region were tight in Q1 2021, as several factories were undergoing maintenance turnarounds throughout the first half of the year. Then, in mid-February, production was disrupted owing to freezing weather in the US Gulf region, which resulted in massive plant outages. However, demand was on the rise as downstream consumption improved, resulting in a sharp increase in regional prices from 1300 USD/MT in January to 1900 USD/MT on a CFR basis in March 2021.

Supplies improved in Q2 as the US Gulf region's industrial infrastructure recovered and heavy aromatic crackers functioned at higher rates. Due to strong domestic demand for Styrenics such as ABS and Polystyrene, Styrolution and LyondellBasell withdrew the force majeures. Adding to the tightness seen in Q1 as a result of storm-related interruptions, procuring spot material in the US market appeared to be much more difficult. Large margins were noted among buyers from downstream Polystyrene (PS) production units. With FOB Texas discussion valued at 1360 USD/MT in June, the pricing pattern showed a progressive easing equal to market supplies.

The market underwent instability in the third quarter of 2021. As Hurricane Ida made landfall on the Gulf Coast of the United States, the AmSty manufacturing facility at Saint James, Louisiana, with a production capacity of 950 KTPA, was shut down preemptively, affecting the pricing of the monomer in the region. Despite the fact that the impact was substantially smaller than that of winter storm Uri, supply remained poor owing to supply chain interruptions caused by hurricane Ida, which aggravated logistical issues in the United States. During the last week of September, the price was 1310 USD/MT.

Styrene Price Trend For the Year 2020

Asia

Ample inventories of styrene in China, along with unfavourable offtakes, casted a pall over the Southeast Asian market's fundamentals. Several firms, including SP Chemical and Abel Chemical, performed a fast turnaround in their production units to balance the narrowed demand and supply gap. Although regional fundamentals improved, inventory levels in China did not shift significantly, as numerous firms continued to operate at levels above 80% of market competency.

In August, styrene prices remained range bound between 650-680 USD/MT CFR China, in line with the bleak market picture. By the conclusion of the quarter, demand for polystyrene and ABS had returned to normal, leaving just standalone styrene makers in the red. In addition, demand fundamentals in Northeast Asia improved as a result of improved downstream consumption and longer import delays from abroad.

Europe

Since the end of August, several manufacturing and downstream industries completed scheduled turnarounds, which helped to restore demand supply fundamentals in the European region. Producers were heard operating at lower rates in order to avoid losses caused by market volatility. In September, demand for downstream derivatives such as ABS and SAN increased significantly, owing to an increase in demand for automobiles, electronics, consumer appliances, and furniture. However, owing to Covid-19, demand from the construction industry remained cloaked in containment measures, with the UK and Russia leading the way with double-digit declines.

North America

Despite many maintenance turnarounds and forced outages due to fears of a series of seasonal hurricanes, the supply in North America was found to be adequate. Styrolution, a major player in the United States, announced the closure of two of its styrene plants in Texas and Bayport. Furthermore, in the second half of the third quarter, turnarounds at derivative Polystyrene and SBR (Styrene Butadiene Rubber) factories weighed on demand fundamentals. Despite this, a modest increase in the demand from the automotive sector provided a ray of optimism for the industry's overall demand fundamentals. By the conclusion of the third quarter, the supply overhang had been resolved by a revival of demand from Asian countries such as Taiwan and South Korea.

Procurement Resource provides latest prices of Styrene. Each price database is tied to a user-friendly graphing tool dating back to 2014, which provides a range of functionalities: configuration of price series over user defined time period; comparison of product movements across countries; customisation of price currencies and unit; extraction of price data as excel files to be used offline.

About Styrene

Styrene is an organic compound derived from benzene. In appearance, it is a colourless oily liquid that evaporates quickly while leaving behind a sweet smell. Styrene is often composed of other chemicals that give it a sharp, unpleasant smell. It dissolves in some liquids but doesn't dissolve easily in water. It tends to polymerise readily at temperatures of more than 90°C. Styrene monomer finds wide applications in both the plastics and the synthetic rubber industries.

Styrene Product Details

| Report Features | Details |

| Product Name | Styrene |

| Chemical Formula | C8H8 |

| Industrial Uses | Latex, Polystyrene and copolymers, Synthetic rubber, Polystyrene resins, Solid and film polystyrene, Packaging materials, As insulation for electrical uses, Fibreglass, Plastic components, Automobile parts, CD cases |

| Molecular Weight | 104.15 g/mol |

| Synonyms | 100-42-5, Ethenylbenzene, Phenylethylene, Vinylbenzene, Phenylethene, Cinnamene, Styrol, Diarex HF 77, Styrolene, Styropol |

| Supplier Database | LyondellBasell Industries Holdings B.V., Reliance Industries Limited, Shell Chemicals, Acros Organics, Central Drug House, SABIC |

| Region/Countries Covered | Asia Pacific: China, India, Indonesia, Pakistan, Bangladesh, Japan, Philippines, Vietnam, Iran, Thailand, South Korea, Iraq, Saudi Arabia, Malaysia, Nepal, Taiwan, Sri Lanka, UAE, Israel, Hongkong, Singapore, Oman, Kuwait, Qatar, Australia, and New Zealand Europe: Germany, France, United Kingdom, Italy, Spain, Russia, Turkey, Netherlands, Poland, Sweden, Belgium, Austria, Ireland Switzerland, Norway, Denmark, Romania, Finland, Czech Republic, Portugal and Greece North America: United States and Canada Latin America: Brazil, Mexico, Argentina, Columbia, Chile, Ecuador, and Peru Africa: South Africa, Nigeria, Egypt, Algeria, Morocco |

| Currency | US$ (Data can also be provided in local currency) |

| Supplier Database Availability | Yes |

| Customization Scope | The report can be customized as per the requirements of the customer |

| Post-Sale Analyst Support | 360-degree analyst support after report delivery |

Note: Our supplier search experts can assist your procurement teams in compiling and validating a list of suppliers indicating they have products, services, and capabilities that meet your company's needs.

Styrene Production Processes

- Production of Styrene via Dehydrogenation of Ethylbenzene; from Benzene and Ethane; and from Toluene and Methanol.

Styrene is produced predominately from ethylbenzene. In this process, ethylbenzene is dehydrogenated using superheated steam (up to 600°C) in the presence of an iron (III) oxide catalyst. Typical catalysts are based on ferric oxide with the additives chromia (Cr2O3) (stabiliser) and potassium oxide (coke retardant).

Methodology

The displayed pricing data is derived through weighted average purchase price, including contract and spot transactions at the specified locations unless otherwise stated. The information provided comes from the compilation and processing of commercial data officially reported for each nation (i.e. government agencies, external trade bodies, and industry publications).

Assistance from Experts

Procurement Resource is a one-stop solution for businesses aiming at the best industry insights and market evaluation in the arena of procurement. Our team of market leaders covers all the facets of procurement strategies with its holistic industry reports, extensive production cost and pre-feasibility insights, and price trends dynamics impacting the cost trajectories of the plethora of products encompassing various industries. With the best analysis of the market trends and comprehensive consulting in light of the best strategic footstep, Procurement Resource got all that it takes.

Client's Satisfaction

Procurement Resource has made a mark for itself in terms of its rigorous assistance to its clientele. Our experienced panel of experts leave no stone unturned in ensuring the expertise at every step of our clients' strategic procurement journey. Our prompt assistance, prudential analysis, and pragmatic tactics considering the best procurement move for industries are all that sets us apart. We at Procurement Resource value our clients, which our clients vouch for.

Assured Quality

Expertise, judiciousness, and expedience are the crucial aspects of our modus operandi at Procurement Resource. Quality is non-negotiable, and we don't compromise on that. Our best-in-class solutions, elaborative consulting substantiated by exhaustive evaluation, and fool-proof reports have led us to come this far, making us the ‘numero uno' in the domain of procurement. Be it exclusive qualitative research or assiduous quantitative research methodologies, our high quality of work is what our clients swear by.

Related News

Table Of Contents

Our Clients

Get in Touch With Us

UNITED STATES

Phone:+1 307 363 1045

INDIA

Phone: +91 8850629517

UNITED KINGDOM

Phone: +44 7537 171117

Email: sales@procurementresource.com

.webp)

.png)

.webp)