Sumitomo Chemicals sets forth with its pilot plant to carry out a single-step process for producing propylene

- Sumitomo Chemical has launched a pilot plant in Sodegaura to demonstrate its innovative single-step process for producing propylene directly from ethanol, supported by the NEDO Green Innovation Fund.

- This technology simplifies conventional production by eliminating intermediate steps, potentially reducing costs while generating hydrogen as a valuable by-product, especially when using bioethanol.

- Aiming for commercialization and licensing by the early 2030s, the initiative supports a broader industry shift from fossil fuels to sustainable feedstocks like biomass and waste-derived ethanol.

Sumitomo Chemical has initiated operations at a new pilot plant located at its Sodegaura facility within the Chiba Works, dedicated to testing an innovative proprietary method for producing propylene directly from ethanol. Supported by the NEDO Green Innovation Fund, this advancement is poised to play a significant role in helping the petrochemical sector transition toward more sustainable raw materials. The company plans to expedite its demonstration efforts with the goal of commercializing the technology and offering it through licensing agreements by the beginning of the next decade.

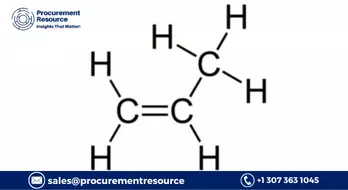

As a fundamental building block in chemical manufacturing, propylene is currently derived in Japan primarily from naphtha, a fossil fuel source. In contrast, ethanol can be sourced from renewable biomass including sugarcane, corn, and non-food sources such as wood pulp. Recent technological improvements have also enhanced the potential for generating ethanol from combustible waste, bringing industrial-scale production within reach. With growing emphasis on sustainable chemical feedstocks, ethanol is increasingly viewed as a viable alternative to conventional petroleum-derived inputs.

- Conventional Model (Naphtha Cracking)

Naphtha (C6H14) → Propylene (C3H6) + Other Products (e.g., CH4, C2H4, C4H8, H2)

- New Proposed Process (Direct Ethanol-to-Propylene)

2 C2H5OH (Ethanol) → C3H6 (Propylene) + CO2 + 3 H2

This newly developed process differentiates itself by converting ethanol into propylene in a single reaction step, bypassing intermediate compounds like ethylene. This direct pathway is anticipated to lower production expenses. An additional benefit of the method is the concurrent production of hydrogen as a by-product. When bioethanol is used as the feedstock, this feature enables the simultaneous generation of bio-based hydrogen, adding further value and sustainability benefits.

Looking ahead, Sumitomo Chemical will focus on gathering essential technical and operational data to facilitate full-scale implementation. It also intends to carry out market outreach for polypropylene manufactured from the renewably sourced propylene. The company has set a target to introduce the technology commercially and begin licensing by the early 2030s.

Read More About Propylene Production Cost Reports - Request Free Sample Copy in PDF

As part of this transformation, the company is implementing structural reforms domestically and internationally, while also expanding its technology licensing and catalyst business. Beyond 2030, Sumitomo aims to establish a green transformation (GX) solutions model, building circular value chains in collaboration with material suppliers and end-product brands, and creating monetization mechanisms for CO2 reduction achieved by its clients.

.webp)